3.4.3 Example of How to Program the Speed Control

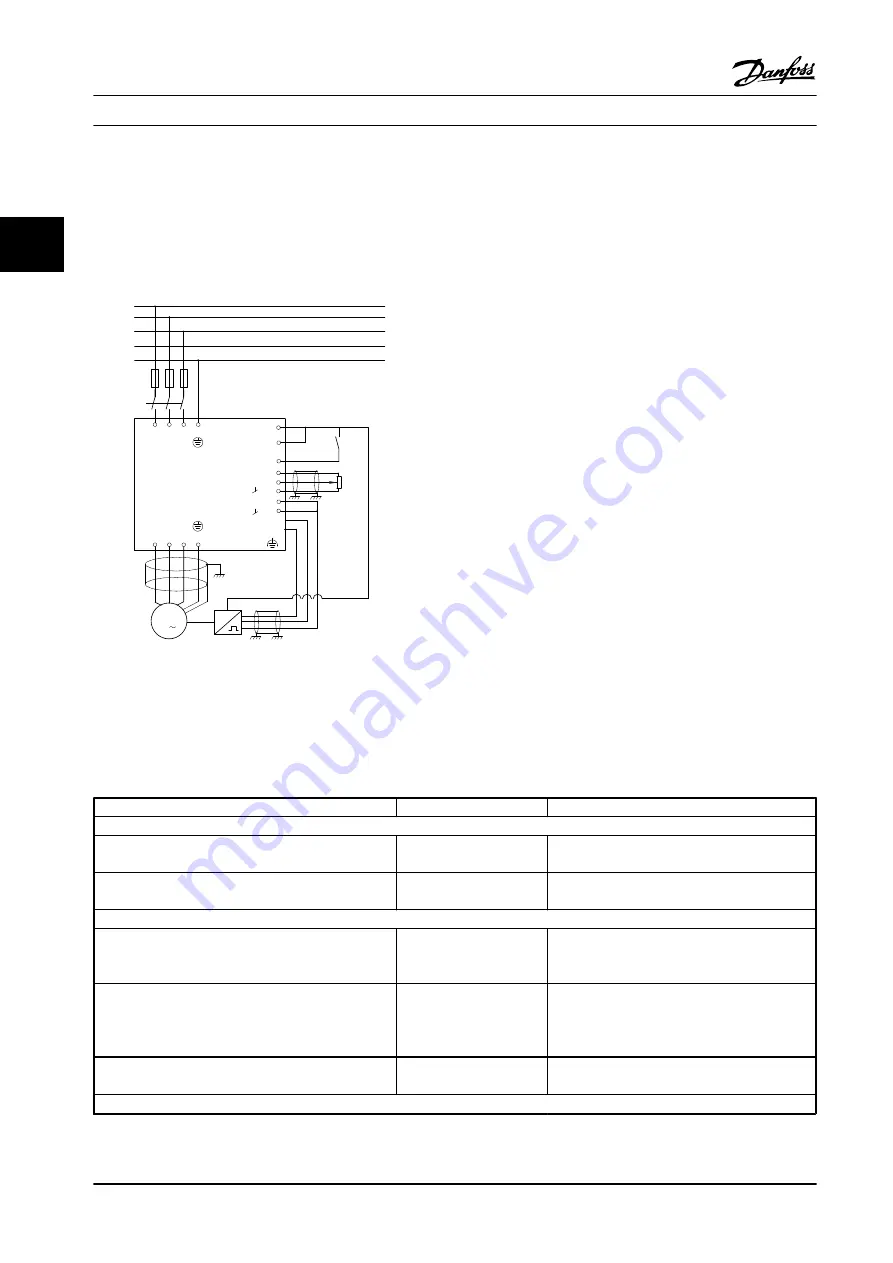

In this case, the speed PID control is used to maintain a constant motor speed regardless of the changing load on the

motor. The required motor speed is set via a potentiometer connected to terminal 53. The speed range is 0–1500 RPM

corresponding to 0–10 V over the potentiometer. Starting and stopping is controlled by a switch connected to terminal 18.

The Speed PID monitors the actual RPM of the motor by using a 24 V (HTL) incremental encoder as feedback. The feedback

sensor is an encoder (1024 pulses per revolution) connected to terminals 32 and 33.

M

3

96 97

99

98

91 92 93 95

50

12

L1 L2

L1

PE

L3

W PE

V

U

F1

L2

L3

N

PE

18

53

37

55

20

32

33

39

24 Vdc

130BA174.10

Figure 3.21 Speed Control Connections

3.4.4 Speed PID Control Programming Order

The following must be programmed in the order shown (see explanation of settings in the

VLT

®

AutomationDrive

Programming Guide

). In

, it is assumed that all other parameters and switches remain at their default settings.

Function

Parameter no.

Setting

1) To ensure the motor runs properly, do the following:

Set the motor parameters according to the nameplate

data.

1-2* Motor Data

As specified by motor nameplate

Perform Automatic Motor Adaptation (AMA).

1-29 Automatic Motor

Adaptation (AMA)

[1] Enable complete AMA

2) Check that the motor is running and that the encoder is attached properly. Do the following:

Press [Hand On]. Check that the motor is running and

note in which direction it is turning (henceforth referred

to as the “positive direction”).

Set a

positive

reference.

Go to

16-20 Motor Angle

. Turn the motor slowly in the

positive direction. It must be turned so slowly (only a

few RPM) that it can be determined if the value in

16-20 Motor Angle

is increasing or decreasing.

16-20 Motor Angle

N.A. (read-only parameter) Note: An increasing

value overflows at 65,535 and starts again at 0.

If

16-20 Motor Angle

is decreasing, then change the

encoder direction in

5-71 Term 32/33 Encoder Direction

.

5-71 Term 32/33 Encoder

Direction

[1] Counter-clockwise (if

16-20 Motor Angle

is

decreasing)

3) Make sure the drive limits are set to safe values.

Product Introduction

Design Guide

38

Danfoss A/S © Rev. 2014-02-10 All rights reserved.

MG34S222

3

3

Summary of Contents for VLT AutomationDrive FC 300

Page 2: ......