Page 85

Ci Scanner Service Manual

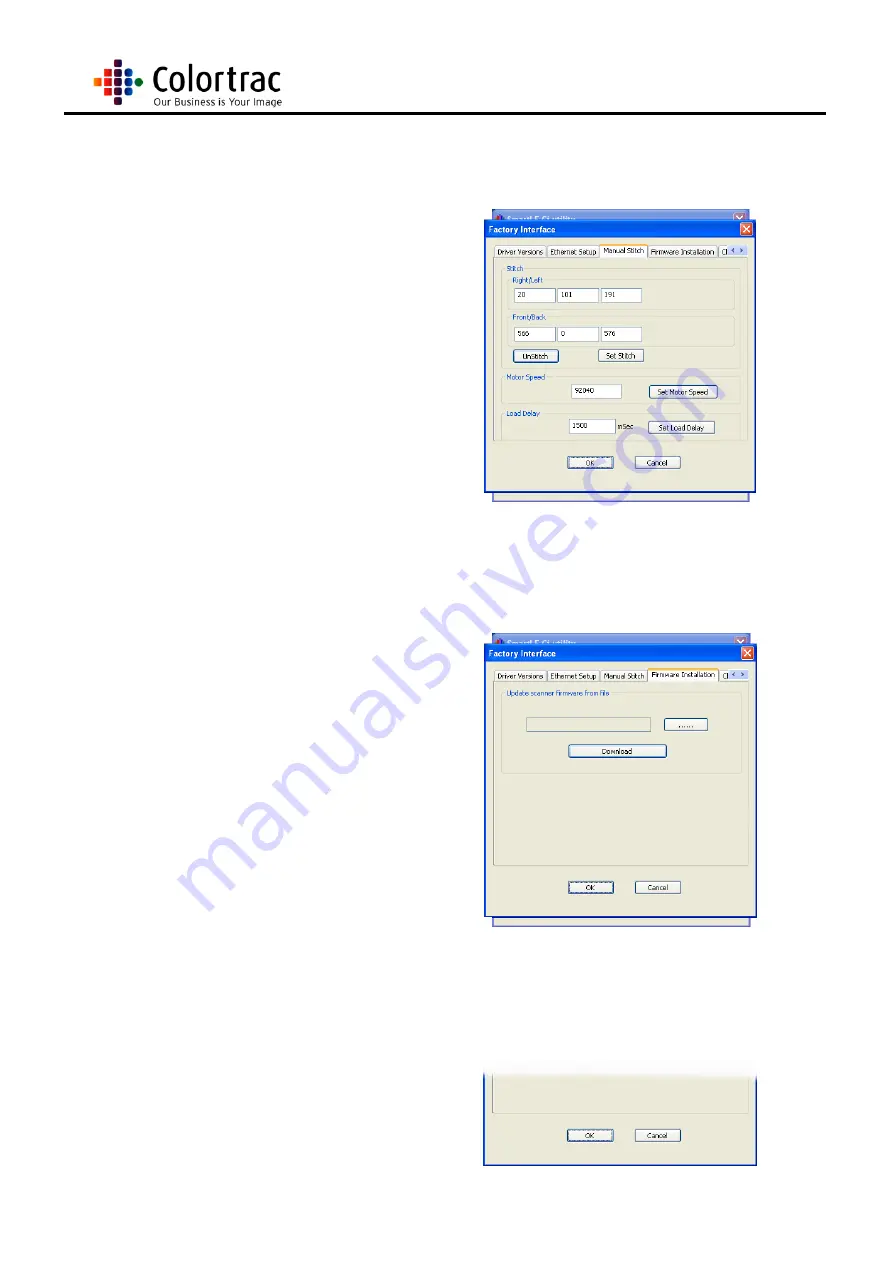

8. The Manual Stitch tab

allows for manual

adjustments to be made to

the stitch values, and

correct any differences

between CIS arrays.

9. Set Motor Speed. This can

be adjusted by over writing

a value and clicking ‘Set

Motor Speed’

10. Set Load Delay changes

the time it takes for media

to me taken in by the

scanner. 1500mSec equals

1.5 seconds, increase this

for a longer delay.

(Image shown is the stitch layout for the Ci24 with 3 CIS)

11. Firmware Installation will

allow the firmware to be

updated. The firmware can

be downloaded from the

website, or sent via email,

and stored on the PC

connected to the scanner.

Use the browse button

(“…..”) to find the stored

file, and ‘Download’ to

update the file into the

scanner*. Restart the

scanner and software on

completion.

* IMPORTANT NOTE: UNDER NO CIRCUMSTANCES MUST

COMMUNICATION BE LOST WITH THE SCANNER DURING

FIRMWARE DOWNLOAD AS THIS WILL DESTROY THE MAIN

BOARD

12.

Click ‘OK’ to close the

utilities screen.

Summary of Contents for SmartLF Ci 40

Page 12: ...Page 12 Ci Scanner Service Manual...

Page 40: ...Page 40 Ci Scanner Service Manual 13 Close the Lid Unit...

Page 45: ...Page 45 Ci Scanner Service Manual 7 Close the Lid Unit...

Page 96: ...Page 96 Ci Scanner Service Manual...

Page 97: ...Page 97 Ci Scanner Service Manual...

Page 98: ...Page 98 Ci Scanner Service Manual 17 4 MAIN BOARD...

Page 99: ...Page 99 Ci Scanner Service Manual...

Page 100: ...Page 100 Ci Scanner Service Manual...