12

English

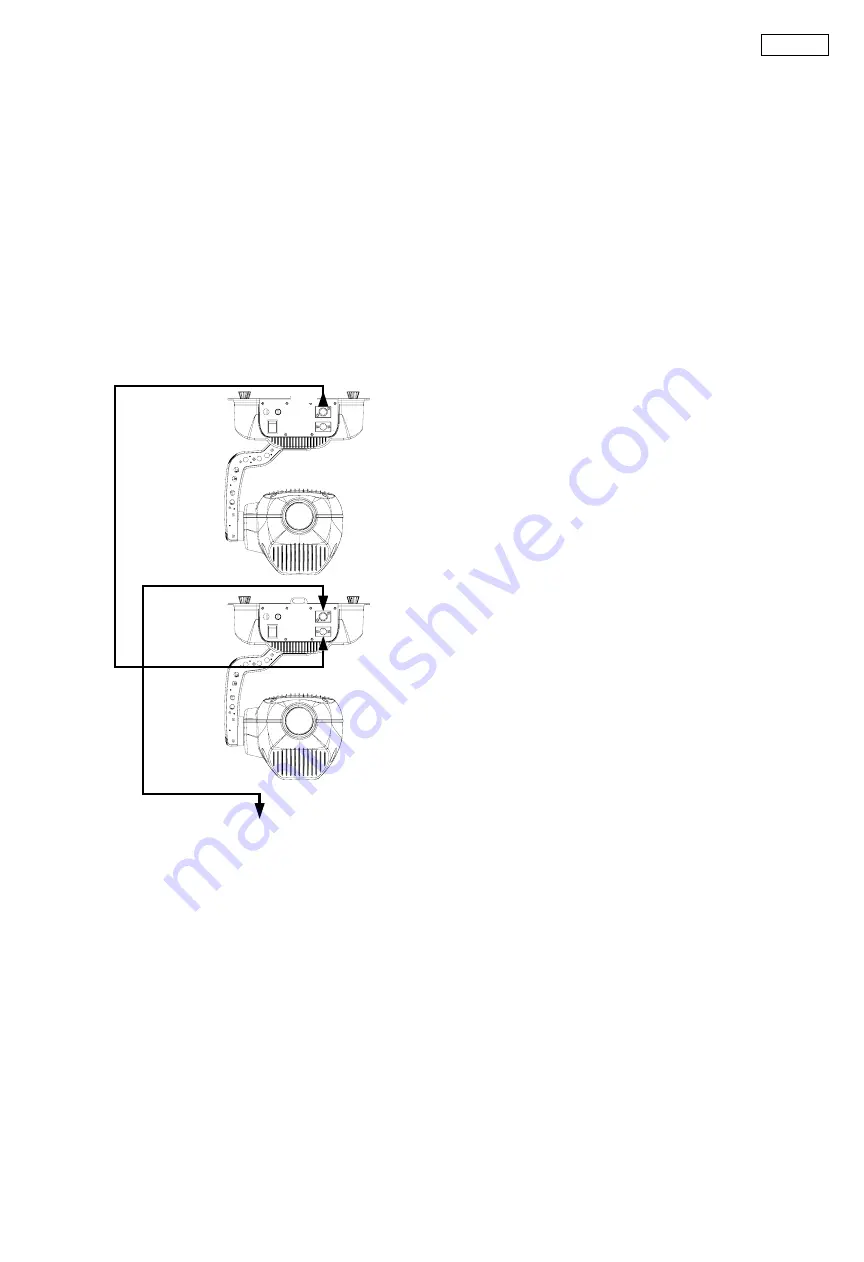

8.3. Synchronising multiple ProSpot 150 LX fixtures without DMX

The output of multiple

ProSpot 150 LX

units may be synchronised without using an incoming DMX 512 signal, by utilising the fix-

ture’s synchronising signal and internally stored programs.

Multiple

ProSpot 150 LX

fixtures may be utilised, operating in sequence and controlled by a MASTER fixture controlling multiple

SLAVE units.

Selecting which

ProSpot 150 LX

is to be utilised as the MASTER is simply a matter of which fixture allows easiest access to the LED

display and menu buttons:

Connect the XLR3 output of the master unit to the XLR input of the first slave unit. The XLR output of the first slave is then connec-

ted to the XLR input of the second slave, and so on up to a maximum total of 32 projectors.

If connecting more than 10 units, we recommend the us of a suitable opto-isolated connecting unit to amplify the signal as requi-

red.

Pin connections conform to the international standard:

pin 1= gnd

pin 2= data –

pin 3= data +

Ensure that all data conductors are isolated from one another and the metal housing of the connector.

Note: the housing of the cannon XLR connectors being used must be isolated

.

Ad altri

ProSpot 150 LX

(slave)

Connect to other

ProSpot 150 LX

(slave)

out

in

out

master

slave