the tension of the chain. Check whether the chain is

seated correctly all around the bar (Fig. 5).

2. After adjusting – the tip of the bar still pointing upward

– fully tighten the bar fastening nuts. The chain is

tensioned correctly if it is seated closely and can be

manually pulled (wear protective gloves!) all the way

around the bar.

NOTE:

If the chain cannot be pulled around the bar

smoothly, but is sluggish or even blocks, the tension is

too high. In this case, do the following minor adjustments:

A. Loosen the 2 bar fastening nut until they are finger-

tight. Decrease the tension by slowly turning the

adjusting screw ANTICLOCKWISE. Pull the chain back

and forth on the bar. Repeat this until the chain can be

moved smoothly, but is still seated closely. To increase

the tension turn the adjusting screw CLOCKWISE.

B. If the saw chain has the correct tension push the tip of

the bar fully upward and tighten the 2 bar fastening nuts.

ATTENTION ! A new chain will stretch so that read-

justment will be required after about 5 cuts. This is

normal for new chains.

ATTENTION ! If the saw chain is TOO LOOSE or TOO

TIGHT the teeth, bar, chain, and crankshaft bearing

will be subject to increased wear and tear. Fig. 6

indicates the correct cold (A) and warm tension (B)

as well as the too low tension of the saw chain (C).

MECHANICAL TEST OF THE CHAIN BRAKE

The chain saw is equipped with a chain brake designed to

reduce the risk of injuries resulting from kickbacks. The

brake actuates if the brake lever experiences pressure

as it would, for example, be the case when a kickback

occurs and the operator’s hand suddenly hits the lever. If

the brake is actuated the chain stops abruptly.

ATTENTION !

The chain brake has the function to reduce

the risk of injuries resulting from kickbacks; however, it

cannot offer a proper protection if the saw is used

carelessly. Check the chain brake before each use of the

saw and repeat the check in the course of your work.

CHECKING THE CHAIN BRAKE

1. The chain brake is DISENGAGED (chain can move) if

the BRAKE LEVER IS PULLED BACK AND LOCKED

(Fig. 7A).

2. The chain brake is ENGAGED (chain is blocked) if the

brake lever is pulled forward. In this case, the chain

must be immovable (Fig. 7B).

NOTE:

The brake lever should lock into place in both

positions. Do not use the saw if you realise a strong

resistance or the lever cannot be shifted. Take it to a

professional technical service point to have it repaired

immediately.

FUEL AND OIL

FUEL

For a maximum performance of your chain saw, use regular

petrol (two-star, unleaded) mixed with a special 40:1 2-

stroke engine oil. Please adhere to the mixing instructions.

ATTENTION !

Do not use pure petrol without oil for

this saw. This will damage the engine and you will

loose your warranty rights. Do not use fuel mixtures

that have been stored for more than 90 days.

ATTENTION !

Do not use any 2-stroke oil products

with a mixture ratio of 100:1. Inappropriate lubrication

will damage the engine and you will loose your

warranty covering the engine.

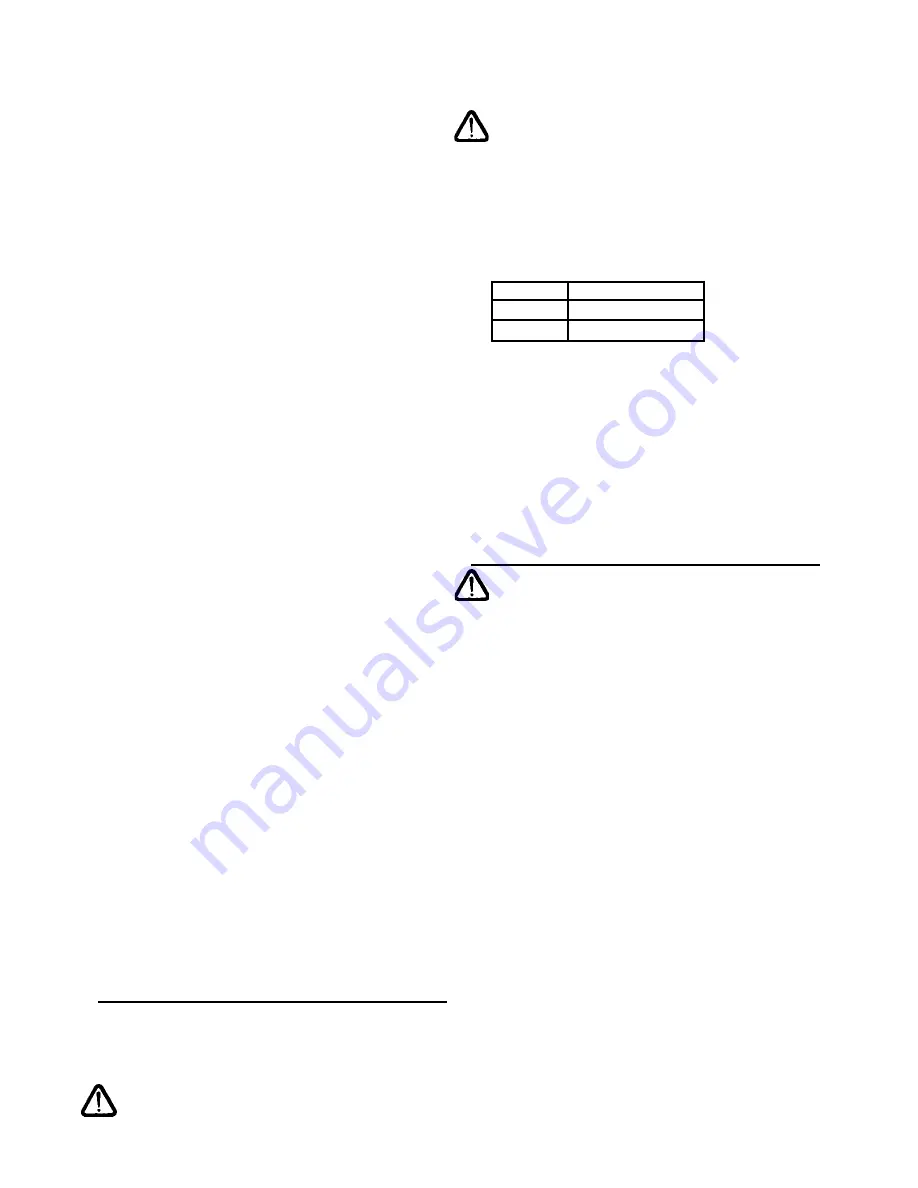

FUEL MIXTURE

Mix the fuel with 2-stroke oil in an approved container.

Refer to the mixing table to find the required mixture ratio

for the fuel and oil. Shake the container to properly mix

the two fluids.

Petrol

2-stroke oil/40:1

1 Litre

25 ml

5 Litre

125 ml

ATTENTION ! If you should you use an improper mixture

ratio you will loose your warranty rights.

RECOMMENDED FUELS

Some common petrol brands have additives like alcohol or

ether compounds to meet the standards for cleaner exhaust

gases. The engine runs satisfactorily with all sorts of petrol.

CHAIN OIL

The chain oil tank must be filled every time you fill the

fuel tank. We recommend the use of special chain oil.

CHECKS BEFORE STARTING THE ENGINE

ATTENTION !

Do never start or operate the saw if

the bar and chain are not properly assembled.

1. Fill the fuel tank (A) with the proper fuel mixture (Fig. 8).

2. Fill the oil tank (B) with the proper chain and bar oil

(Fig. 8).

3. Make sure that the chain brake (C) has been disen-

gaged before the engine is started (Fig. 8).

STARTING THE ENGINE

There are 3 starter positions: BETRIEB (OPERATION) (A),

HALB (HALF THROTTLE) (B), and CHOKE (C) (Fig. 9A).

1. To start the engine slide the red STOP switch (D) upward

(Fig. 9B).

2. Put the yellow choke actuating lever (E) in position

(CHOKE) (Fig. 9C).

3. Push the button (F) of the fuel pump 10 times (Fig. 9D).

4. Slide the operation lock forward: Push and hold down

the lock (A), push the throttle lever (B), let go of the

throttle lever and then the lock (Fig. 10A).

5. Put the saw on a solid, level rest. Hold the saw as

shown on the picture. Pull the starter 4 times quickly.

Beware of the running chain! (Fig. 10B).

6. Put the yellow choke actuating lever (D) in position

(HALB (HALF)) (Fig. 10C).

7. Hold the saw fast and quickly pull the starter 4 times.

The engine should start now (Fig. 10D).

8. Let the engine run up for 10 seconds. Push the throttle

lever (E) and put it in position LEERLAUF (IDLE); proceed

to step 9 (Fig 10E).

9. Put the yellow choke actuating lever (F) in position

(BETRIEB (OPERATION)) (Fig. 10F). If the motor

does not start repeat the steps described above.

GB-4

Summary of Contents for 1735-01 BKS

Page 2: ......

Page 5: ...1 2a 2b 3a 3b 3c 3d 3e A C B D E G F 1 3 2 4 A A A B A B C B 4 ...

Page 6: ...4a 4b 5 6 7a 7b 8 9a 9b A D C B B A B C A C B D B A C 5 ...

Page 7: ...9c 9d 10a 10b 10c 10d 10e 10f E F A B D E F 6 ...

Page 8: ...7 11 12 13 14a 14b 15 16a 16b 16c 17 B C B A A B A 2 2 1 C B A A ...

Page 9: ...8 20a 20b 21 22 23 24 18 19 C B A A B A E F D C B A ...

Page 50: ......

Page 51: ......