72

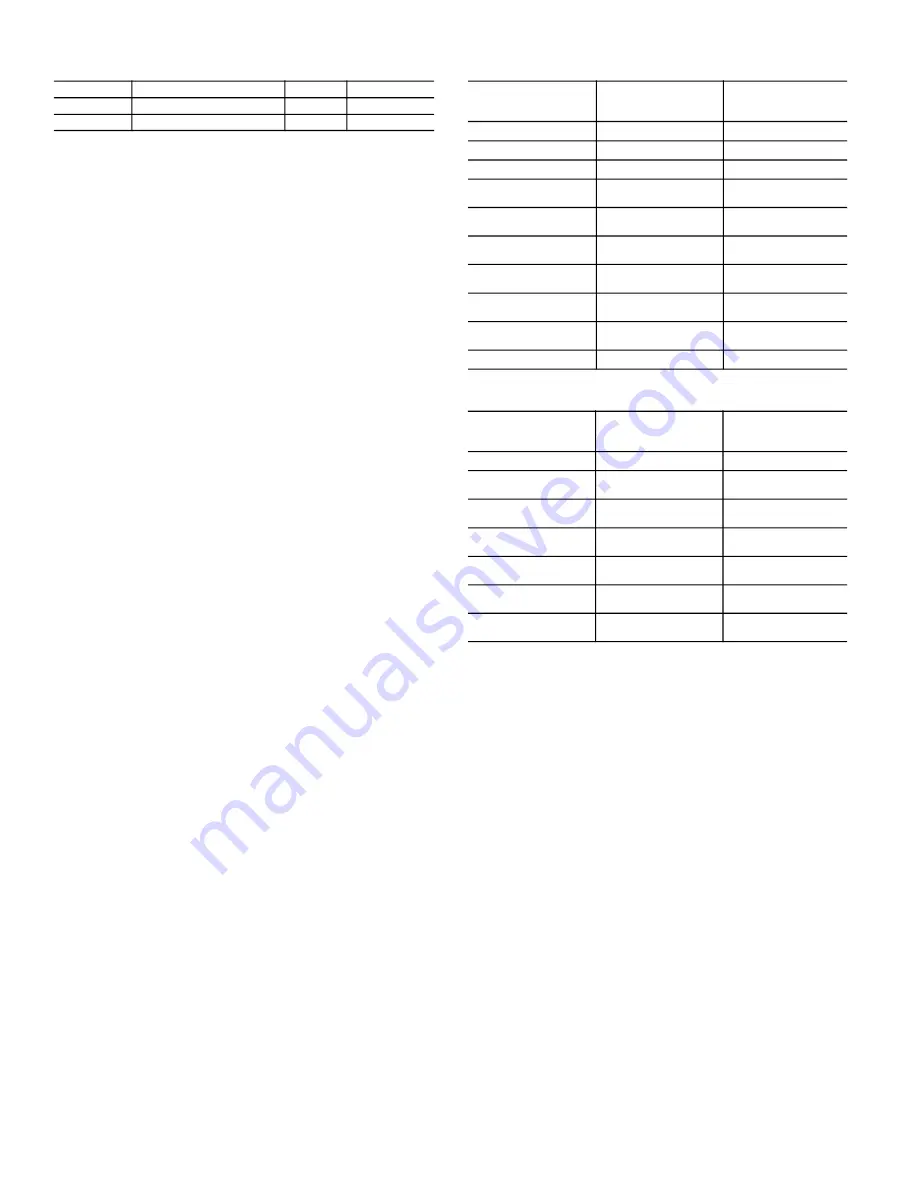

Table 48 —

Fan Status Monitoring Configuration

Fan Stat Monitoring Type (SFS.M)

This configuration selects the type of fan status monitoring to

be performed.

0 - NONE — No switch or monitoring

1 - SWITCH — Use of the fan status switch

2 - SP RISE — Monitoring of the supply duct pressure.

Fan Fail Shuts Down Unit (SFS.S)

This configuration will allow whether the unit should shut

down on a supply fan status fail or simply alert the condition

and continue to run.

YES — Shut down the unit if supply fan status monitoring

fails, and send out an alarm.

NO — Do not shut down the unit if supply fan status monitor

-

ing fails, but send out an alert.

SUPPLY FAN STATUS MONITORING LOGIC

Regardless of whether the user is monitoring a discrete switch

or is monitoring static pressure, the timings for both techniques

are the same and rely upon the configuration of static pressure

control.

The configuration which determines static pressure control is

Configuration

SP

SP.CF

. If this configuration is set to

0 (none), a fan failure condition must wait 60 continuous sec

-

onds before taking action. If this configuration is 1 (VFD), a

fan failure condition must wait 3 continuous minutes before

taking action.

If the unit is configured to monitor a fan status switch (

SFS.M

= 1), and if the supply fan commanded state does not match the

supply fan status switch for 3 continuous minutes, then a fan

status failure has occurred.

If the unit is configured for supply duct pressure monitoring

(

SFS.M

= 2), then

• If the supply fan is requested ON and the static pressure

reading is not greater than 0.2 in. wg for the time clarified

above, a fan failure has occurred.

• If the supply fan is requested OFF and the static pressure

reading is not less than 0.2 in. wg for the time clarified

above, a fan failure has occurred.

Dirty Filter Switch

This unit is equipped with several filter stages. It is important

to maintain clean filters to reduce the energy consumption of

the system. This unit is designed to provide several ways to

achieve this goal. Table 49 shows the 9 configurations for filter

monitoring in this unit. If the configuration for either the main

or final filter is set to 0-Disable then the input is set to read

“Clean all the time.” There are several controls which need to

be used in conjunction with the filter configuration so that each

corresponding setting will operate correctly.

The fault status timer is a parameter that sets the number of

minutes the filter status must be in a fault state before the fault

latch is closed. To set the fault time, use

Configuration

FLTC

FS.FT

; the range is between 0 and 10 minutes. The

default for this parameter is 2 minutes.

Filter types (

MF_TY, PF_TY

) and final resistance (

MF_FR,

PF_FR

) are used for the Delta Pressure and Predictive Life

configurations for the main and post filter. The final resistance

will be automatically set when the filter type is selected. After

selecting a filter type, it is possible to change the filter final re

-

sistance. Settings for filters based on Tables 49 and 50 for main

and post filters.

Table 49 —

Main Filter Types

Table 50 —

Post Filter Types

To change the filter type for the main filter, use

Configura

-

tion

FLTC

MF.TY

set between 0 and 9 according to the

main filter type table. To change the filter type for the post fil

-

ter, use

Configuration

FLTC

PF.TY

set between 0 and 6

according to the post filter type table. To adjust the final resis

-

tance for the main filter after a filter type has been selected, use

Configuration

FLTC

MF.FR

and set from 0 to 10. To ad

-

just the final resistance for the post filter, use

Configura

-

tion

FLTC

PF.FR

and set between 0 and 10.

1 = Switch

If the Filter configuration for either the main or post filter is set

to 1 (Switch), then a filter status switch should be installed.

The monitoring of the filters is based on a clean/dirty switch

input.

Monitoring of the main and post filter status switches is dis

-

abled in the Service Test mode and when the supply fan is not

commanded on. If the fan is on and the unit is not in a test

mode and either the main or post filter status switch reads

“dirty” for a user set continuous amount of time, an alert is

generated. Recovery from this alert is done through a clearing

of all alarms or after cleaning the filter and the switch reads

“clean” for 30 seconds.

2 = Schedule

Filter configuration for either main or post filter can be set to 2

(Schedule). In this mode the filter status is based on a schedule

set by the user. The status is determined by the amount of time

remaining in the filter life. The user sets the lifetime for the fil

-

ter in months from 1 to 60 (5 years). The default for this pa

-

rameter is 12 months. It is also possible to set a reminder and

reset the schedule.

ITEM

EXPANSION

RANGE

CCN POINT

SFS.S

Fan Fail Shuts Down Unit

No/Yes

SFS_SHUT

SFS.M

Fan Stat Monitoring Type

0 to 2

SFS_MON

MAIN FILTER TYPE

(MF_TY)

DESCRIPTION

MAIN FILTER FINAL

RESISTANCE

(MF_FR)

0

Std 2 in. MERV

1

1

4-in. MERV 8

1

2

4-in. MERV 14

1.5

3

12-in. MERV 14

Bag with 2 in. pre-filter

2

4

12-in. MERV 14

Bag with 4 in. pre-filter

2

5

19-in. MERV 15

Bag with 2 in.pre-filter

2

6

19-in. MERV 15

Bag with 4 in. pre-filter

2

7

12-in. MERV 14

Cart with 2 in. pre-filter

2.5

8

12-in. MERV 14

Cart with 4 in. pre-filter

2.5

9

Strion Air

2

POST FILTER TYPE

(PF_TY)

DESCRIPTION

POST FILTER FINAL

RESISTANCE

(PF_FR)

0

None

0

1

12-in. MERV 14 Cart

with 2 in. pre-filter

2.5

2

12-in. MERV 14 Cart

with 4 in. pre-filter

2.5

3

19-in. MERV 15

Bag with 2 in. pre-filter

2

4

19-in. MERV 15

Bag with 4 in. pre-filter

2

5

12-in. MERV 17

Bag with 2 in. pre-filter

3

6

12-in. MERV 17

Bag with 4 in. pre-filter

3

Summary of Contents for WeatherExpert 48N2

Page 135: ...135 Fig 18 48 50N Typical Power Schematic Nominal 075 Ton Unit Shown ...

Page 136: ...136 Fig 19 48 50N Typical Power Schematic Nominal Ton 90 150 Units Shown ...

Page 137: ...137 Fig 20 48 50N Main Base Board Input Output Connections ...

Page 138: ...138 Fig 21 48 50N RXB EXB CEM Input Output Connections a48 9307 ...

Page 139: ...139 Fig 22 48 50N EXV SCB Input Output Connections a48 9308 ...

Page 140: ...140 Fig 23 48N Typical Modulating Gas Heat Unit Control Wiring ...

Page 141: ...141 Fig 24 50N Typical Electric Heat Unit Control Wiring ...

Page 144: ...144 Fig 27 48N Typical Gas Heat Section Wiring Nominal Ton 120 to 150 Units ...

Page 145: ...145 Fig 28 48 50N Typical Power Component Control Wiring 460 v ...

Page 146: ...146 Fig 29 48 50N Component Control Wiring 575 v Nominal Ton 075 to 150 Units ...

Page 147: ...147 Fig 30 48 50N Component Arrangement Power Box ...

Page 148: ...148 Fig 31 48 50N Component Arrangement Control Box ...

Page 240: ...240 APPENDIX D VFD INFORMATION CONT Fig G VFD Bypass Wiring Diagram WHEN USED ...