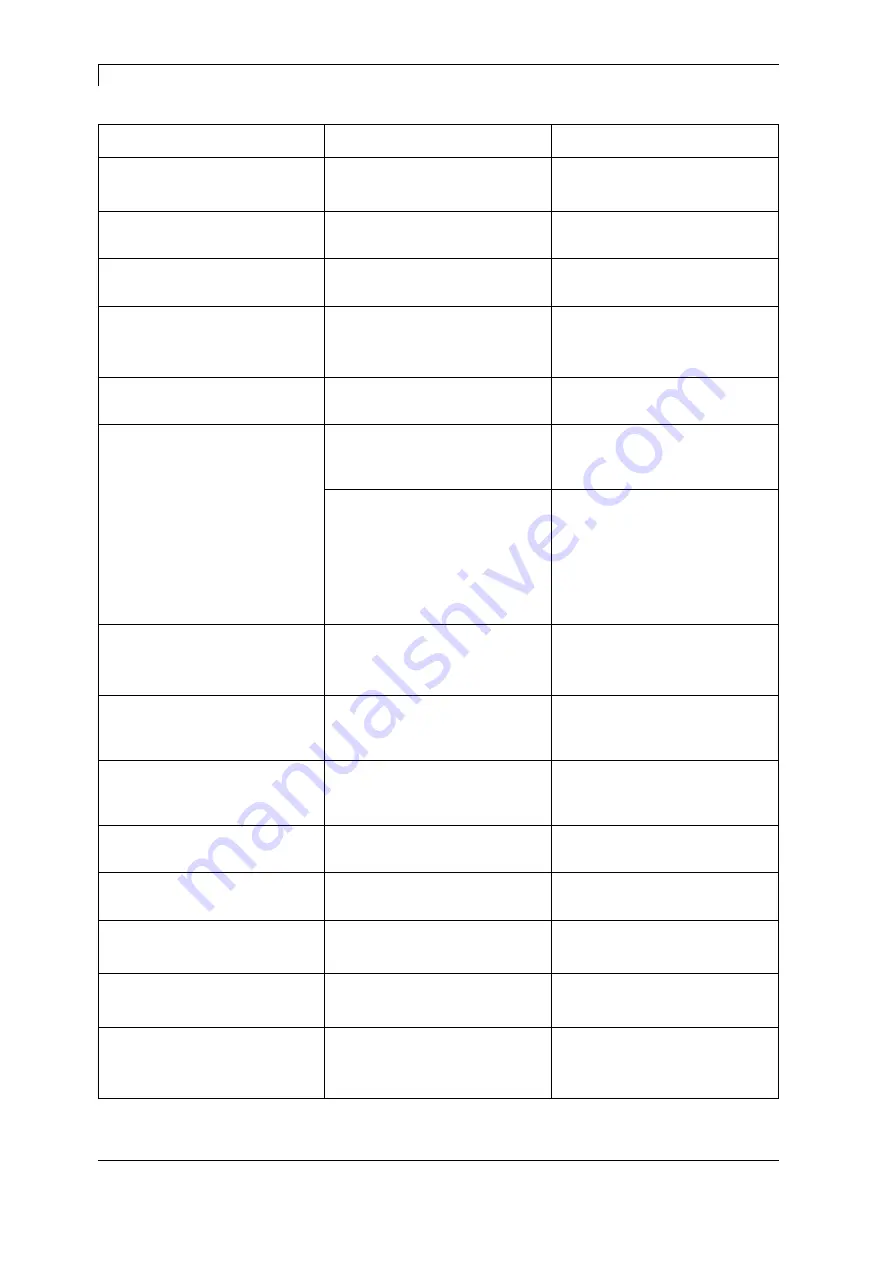

Error Correction

Compa II

100

Operating manual

03.20

Error message

Cause

Remedy

89

RFID timeout

Error at programming the RFID

label.

Label positioning.

Faulty label.

90

RFID data

Faulty or incomplete definition

of RFID data.

Check RFID data definitions.

91

RFID tag type

Definition of label data does not

correspond with the used label.

Check storage partitioning of

used label type

92

RFID lock

Error at programming the RFID

label (locked fields).

Check RFID data definitions.

Label was already

programmed.

93

RFID programming

Error at programming the RFID

label.

Check RFID definitions.

94

Scanner timeout

The scanner could not read the

bar code within the set timeout

time.

Defective printhead.

Wrinkles in transfer ribbon.

Scanner wrong positioned.

Timeout time too short.

Check printhead.

Check transfer ribbon.

Position scanner correctly,

corresponding to the set

feeding.

Select longer timeout time.

95

Scanner layout

difference

Scanner data does not

correspond to bar code data.

Check adjustment of scanner.

Check scanner settings /

connection.

96

COM break

Serial interface error.

Check settings for serial data

transmission as well as cable

(printer-PC).

97

COM general

Serial interface error.

Check settings for serial data

transmission as well as cable

(printer-PC).

98

No software

printhead FPGA

No printhead-FPGA data

available.

Please contact your

responsible distributor.

99

Load software

printhead FPGA

Error when programming

printhead-FPGA.

Please contact your

responsible distributor.

100

Upper position

Option applicator:

Sensor signal up is missing.

Check input signals /

compressed-air supply.

101

Lower position

Option applicator:

Sensor signal down is missing.

Check input signals /

compressed-air supply.

102

Vacuum plate empty

Option applicator:

Sensor does not recognize a

label at vacuum plate.

Check input signals /

compressed-air supply.

Summary of Contents for COMPA II

Page 1: ...COMPA II Operating Manual ...

Page 10: ...Introduction Compa II 10 Operating manual 03 20 ...

Page 16: ...Safety Notes Compa II 16 Operating manual 03 20 ...

Page 26: ...Technical Data Compa II 26 Operating manual 03 20 ...

Page 30: ...Installation Compa II 30 Operating manual 03 20 ...

Page 42: ...Load Media Compa II 42 Operating manual 03 20 ...

Page 64: ...Function menu Compa II 64 Operating manual 03 20 ...

Page 104: ...Error Correction Compa II 104 Operating manual 03 20 ...

Page 112: ...Environmentally Friendly Disposal Compa II 110 Operating manual 03 20 ...