COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-169

3. OPERATION AND TIMING

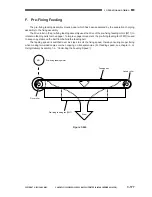

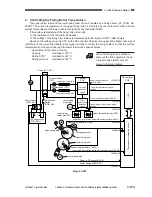

7. Operation of the Transfer Belt Lifter

A mechanism is needed to prevent adhesion of toner on the photosensitive drum to the transfer belt

when the density of Bk toner is measured (See chapter 3. E. Developing Assembly, 4-e. Measuring the

Toner by the SALT Sensor). To prevent adhesion, the drive of the pick-up motor (M10) is transmitted to the

cam through the transfer belt lifter clutch (CL17), thereby lowering (moving away) the transfer belt by the

transfer lifter arm.

When the density of Bk toner has been measured, the transfer belt is moved up back to the point of

transfer.

The lifter movement is monitored with reference to the light-blocking plate (mounted to the cam shaft)

detected by the transfer belt lifter sensor 1 (PS12) and the transfer belt lifter sensor 2 (PS13). (See Table 3-

610.)

If the transfer belt lifter does not reach a specific point over a specific period of time after the transfer belt

lifter clutch has turned on, ‘E074’ will be indicated on the control panel.

Figure 3-638

Photosensitive

drum (Bk)

Photosensitive

drum (C)

Photosensitive

drum (M)

Photosensitive

drum (Y)

Drive roller

Transfer belt

lifter clutch

Transfer lifter arm

Transfer belt

PS12

PS13

CL17

M10

Arm fulcrum

Lifter fulcrum

Light-blocking

plate

Cam

Transfer belt

lifter sensor 1

(PS12)

Transfer belt

lifter sensor 2

(PS13)

Pick-up motor

Cam shaft

Summary of Contents for 1000S

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper ...