3. OPERATION AND TIMING

COPYRIGHT © 2001 CANON INC. CANON CLC1000/1000S/3100 REV.2 MAY 2001 PRINTED IN JAPAN (IMPRIME AU JAPON)

3-108

b.

Measuring the Color Toner Density

The Y, M, and C developing assemblies each are equipped with a color toner density sensor inside them

(Figure 3-535), and each sensor is used to measure the density of toner retained on its respective cylinder.

Figure 3-535

The mechanism of measurement is as follows:

The CLC1000’s developer is a two-component developer consisting of carrier and toner. When exposed

to infrared light, the color toner will reflect infrared light while the carrier will absorb it. In other words, when the

amount of toner decreases because of consumption over time, the reflection of infrared light will decrease

because of the changing toner/carrier ratio of the developer.

Using an infrared diode, the toner/carrier ratio

is computed from the intensity of the infrared light

reflected by the developer on the developing

cylinder.

To make up for the deterioration occurring in

the infrared diode and changes in temperature, the

direct light is also measured at the same time.

Figure 3-536

Y

M

C

CL

Bk

Color toner density sensor

DC controller PCB

Toner supply signal

Transfer belt

Toner supply clutch

Developing

cylinder

Direct intensity/reflected intensity signal

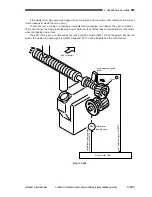

Detection of direct light

Mirror

Cylinder

Detection of

reflected light

LED

Direct intensity signal

Reflected intensity signal

Summary of Contents for 1000S

Page 12: ......

Page 30: ......

Page 44: ......

Page 86: ......

Page 254: ......

Page 372: ......

Page 374: ......

Page 418: ......

Page 438: ......

Page 442: ......

Page 754: ......

Page 764: ......

Page 766: ......

Page 840: ...0501GR PRINTED IN JAPAN IMPRIME AU JAPON This publication is printed on 100 reprocessed paper ...