7. ADJUSTMENTS

S-7300A

118

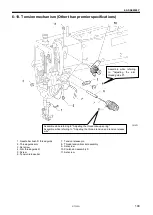

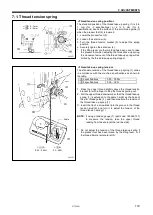

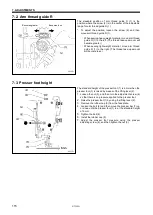

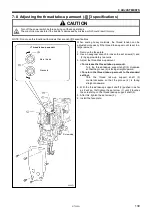

8. Prepare a block (21) with a suitable thickness. Turn the

machine pulley (12) to raise the needle bar (22) so that

the block (21) is clamped by the needle bar bush (23) and

the needle bar thread guide (24). Read the upper shaft

angle at this time (at the position in figure [A]).

9. Remove the block (21), and then turn the machine pulley

(12) again to raise the needle bar (22) until it passes its

highest position and starts to drop. (Figure [B])

Clamp the block (21) between the needle bar bush (23)

and the needle bar thread guide (24) once more. Read the

upper shaft angle at this time (at the position in figure [C]).

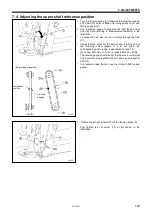

10. Use the upper shaft angles which were read at the

positions in figure [A] and figure [C] to calculate the angle

at the highest needle bar position.

For example, if A=320° and C=20°, the position

relationship is as shown below, and so

B=320°+60°/2=350°.

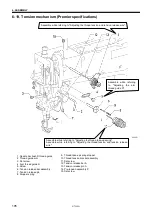

11. Turn the machine pulley (12) to increase the angle from

the highest needle bar position by 55° (for -[][]3

specifications) or 51° (for -[][]5 specifications).

*

For example, if the angle at the highest needle bar

position is 350°, turn the machine pulley (12) so that the

angle is 45° (for -[][]3 specifications) or 41° (for -[][]5

specifications).

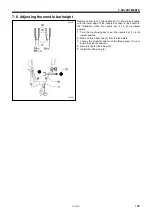

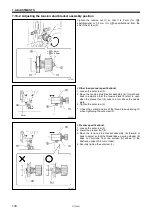

12. Turn off the power.

NOTE:

Do not touch the machine pulley (12).

13. While touching the menu key (16) and the home key (25),

press the power switch (17).

14. Select "U-shaft REF position ADJ" (26).

15. Press the OK key (27).

0986D

0969D

(16)

(25)

(26)

(27)

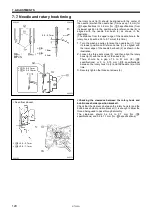

Needle bar passes highest position

Highest needle bar position

[B]

[A]

[C]

B

A

C

30

°

30

°

60

°

320

°

20

°