LB 571 BTwave

6 Start up and Calibration

68847BA2 Rev.00, 10/2020

33

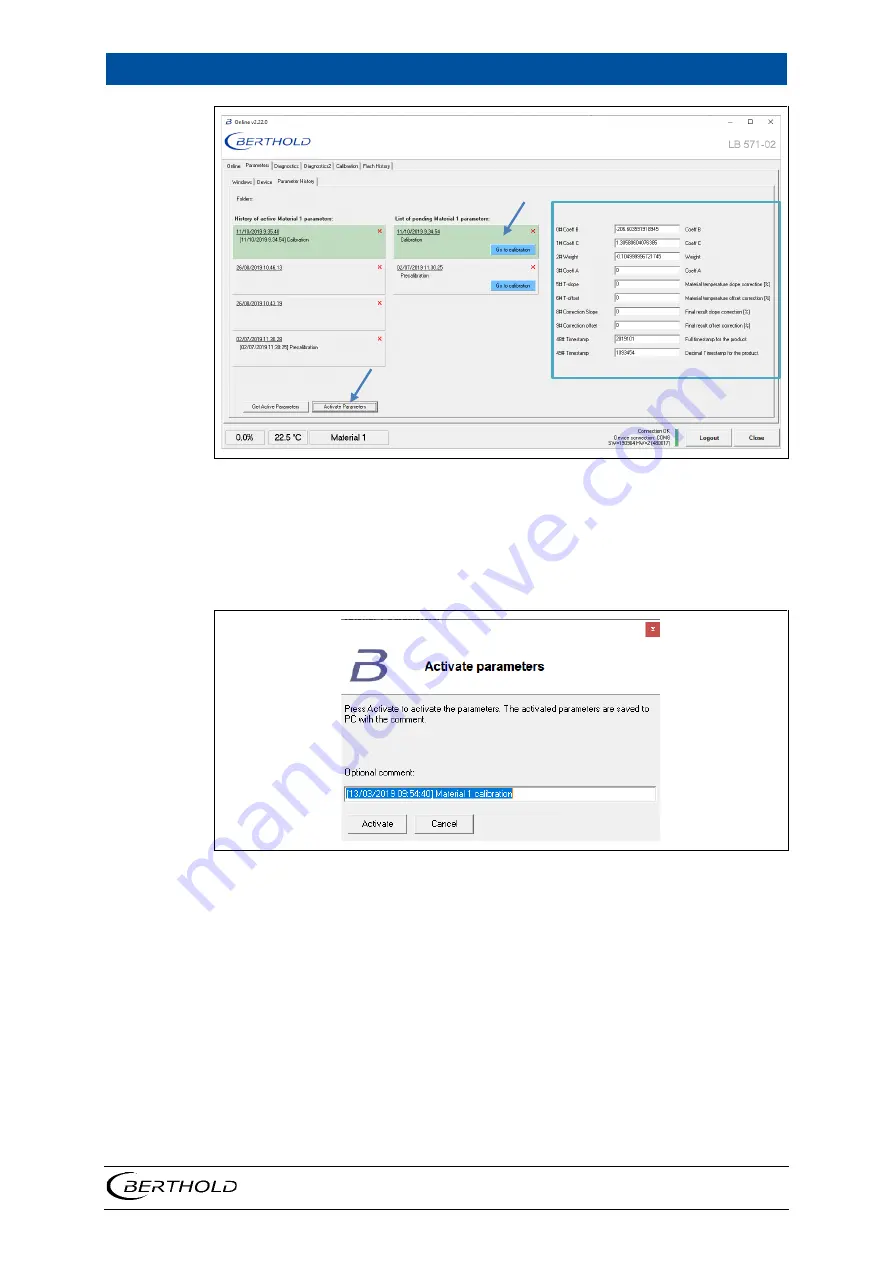

Figure 26 Parameter History

The green marked box appears under

List of pending Material 1 parameters:

. This

is the saved calibration and its calculation parameters can be seen on the right side

on the figure. This calibration still needs to be activated to MCU as follows:

9.

Click

Activate parameters

button and below view opens.

Figure 27 Activate parameters

10.

Add optional comments if needed and click

Activate

button and below

view opens.

Summary of Contents for BTwave LB 571-02

Page 1: ...BTwave LB 571 02 Operating Manual 68847BA2 Rev No 00 01 2020 ...

Page 2: ......

Page 4: ......

Page 24: ...5 Commissioning LB 571 BTwave 20 68847BA2 Rev 00 10 2020 ...

Page 44: ...7 Diagnostics LB 571 BTwave 40 68847BA2 Rev 00 10 2020 ...

Page 48: ...8 Error Codes and Alarms LB 571 BTwave 44 68847BA2 Rev 00 10 2020 ...

Page 50: ...9 Technical Information LB 571 BTwave 46 68847BA2 Rev 00 10 2020 ...