11-3. Initializing the Color

Initializing the color display.

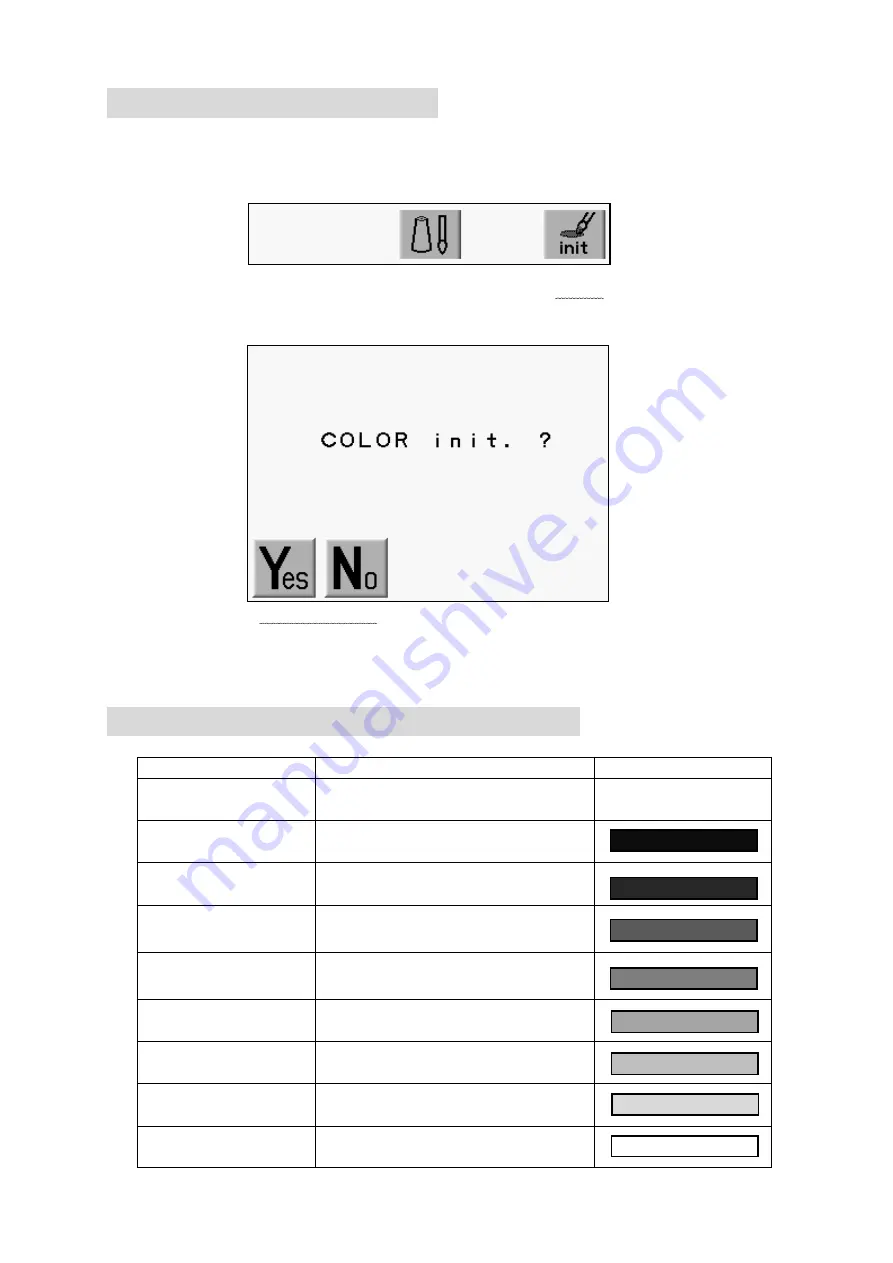

1) refer to “Changing the Color in the Display” and find the Color Set-Up Menu.

2) Press and hold the E-Key for 2 short beeps.

(A-Key) (B-Key) (C-Key) (D-Key) (E-Key)

3) Press the A-Key to start initialization.

(A-Key) (B-Key) (C-Key) (D-Key) (E-Key)

Press the B-Key to Cancel the initialization.

11-4. Items that can have colors changed

Item

Description

Default Color

Shows all the items in the thumb

nail in set color

All

Memory Location, Design file nam

e, Needle No.

No, Name

rpm, st

Speed and Stitch Count

Icon

Icon

Back

Background

The background clor of

(Visual)

design thumbnail

The back ground color for Drive

Mode

(Drive )

The background color for

(Float )

Float

The back ground color for

(NET AB)

Time-Out in the Network System

3-15

Summary of Contents for BEVT Series

Page 1: ...Instruction Manual...

Page 15: ...1 Automat 3 2...

Page 74: ...3 Press the E Key to start loading designs A Key B Key C Key D Key E Key 6 17...

Page 148: ...Embroidery Machine BEVT series Mechanical Guide...

Page 156: ...BEVT Series Mechanical Guide Machine Basics 1 6 Z9 Sewing Head...

Page 159: ...1 9 Machine Basics BEVT Series Mechanical Guide...