28

28

Blade structure

Bi-metal blades are the most commonly used. They consist of a silicon-steel blade backing by a

laser welded high speed steel (HHS) cutting edge. The type of stocks are classified in M2, M42,

M51 and differ from each other because of their major hardness due to the increasing

percentage of Cobalt (Cc) and molybdenum (Mo) contained in the metal alloy.

Blade type

They differ essentially in their constructive characteristics, such as:

•

Shape and cutting angle of tooth

•

Pitch

•

Set

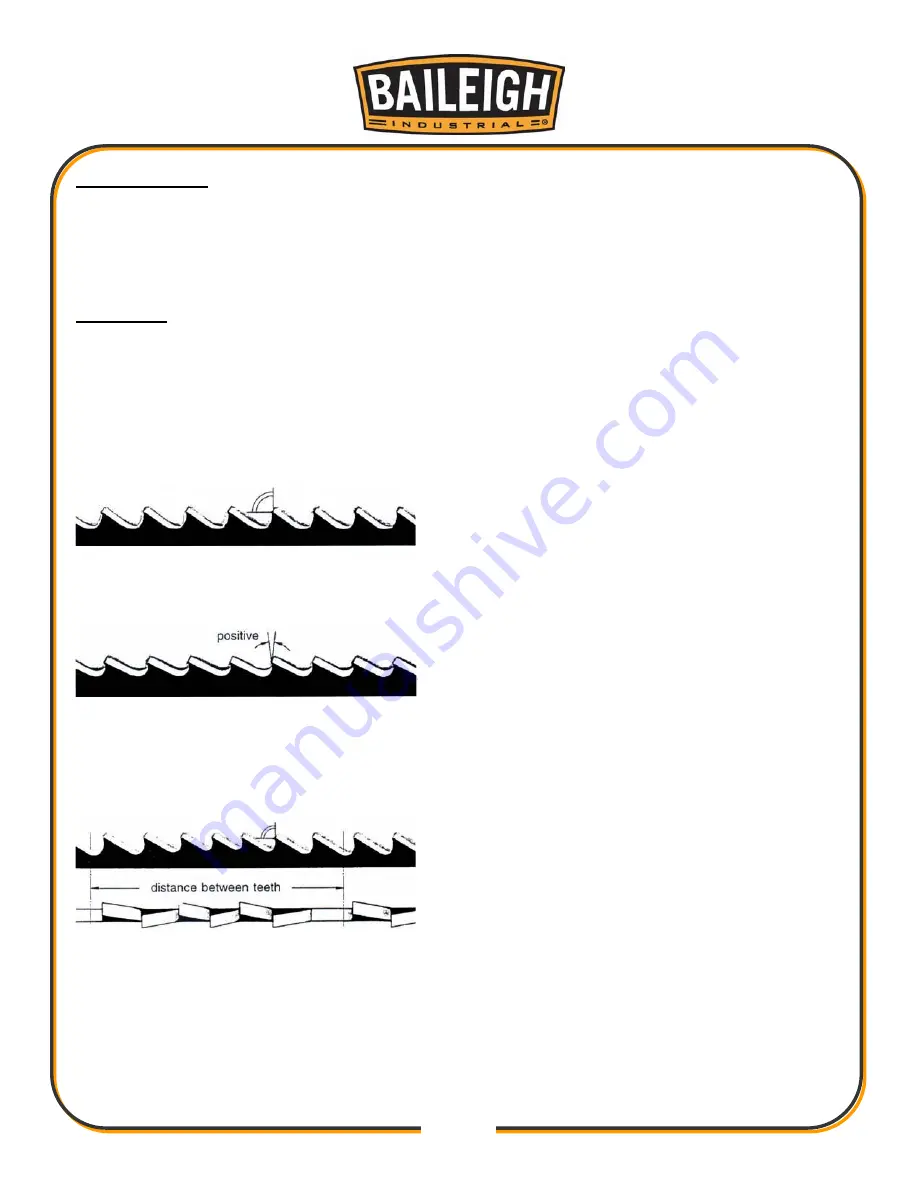

Shape and angle of tooth

REGULAR TOOTH: O° rake and constant pitch.

Most common form for transversal or inclined cutting of solid small and average cross-sections

or pipes, in laminated mild steel and gray iron or general metal.

POSITIVE RAKE TOOTH: 9° - 10° positive rake and constant pitch.

Particular use for crosswise or inclined cuts in solid sections or large pipes, but above all harder

materials (highly alloyed and stainless steels, special bronze and forge pig iron).

COMBO TOOTH: pitch varies between teeth and consequently varying teeth size and varying

gullet depths. Pitch varies between teeth, which ensures a smoother, quieter cut and longer

blade life owing to the lack of vibration.

Another advantage offered in the use of this type of blade in the fact that with an only blade it is

possible to cut a wide range of different materials in size and type.

Summary of Contents for BS-330SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 21: ...18 18 DESCRIPTION OF MACHINE PARTS A G F E H C I J B K L O P Q D M N...

Page 34: ...31 31...

Page 54: ...51 51 ELECTRICAL SCHEMATIC...

Page 55: ...52 52...

Page 56: ...53 53 Terminal Strip Connections...

Page 57: ...54 54 Switch Designation...

Page 59: ...56 56 HYDRAULIC LAYOUT...

Page 61: ...58 58 PARTS DIAGRAM...

Page 62: ...59 59...

Page 75: ...72 72 NOTES...