49

49

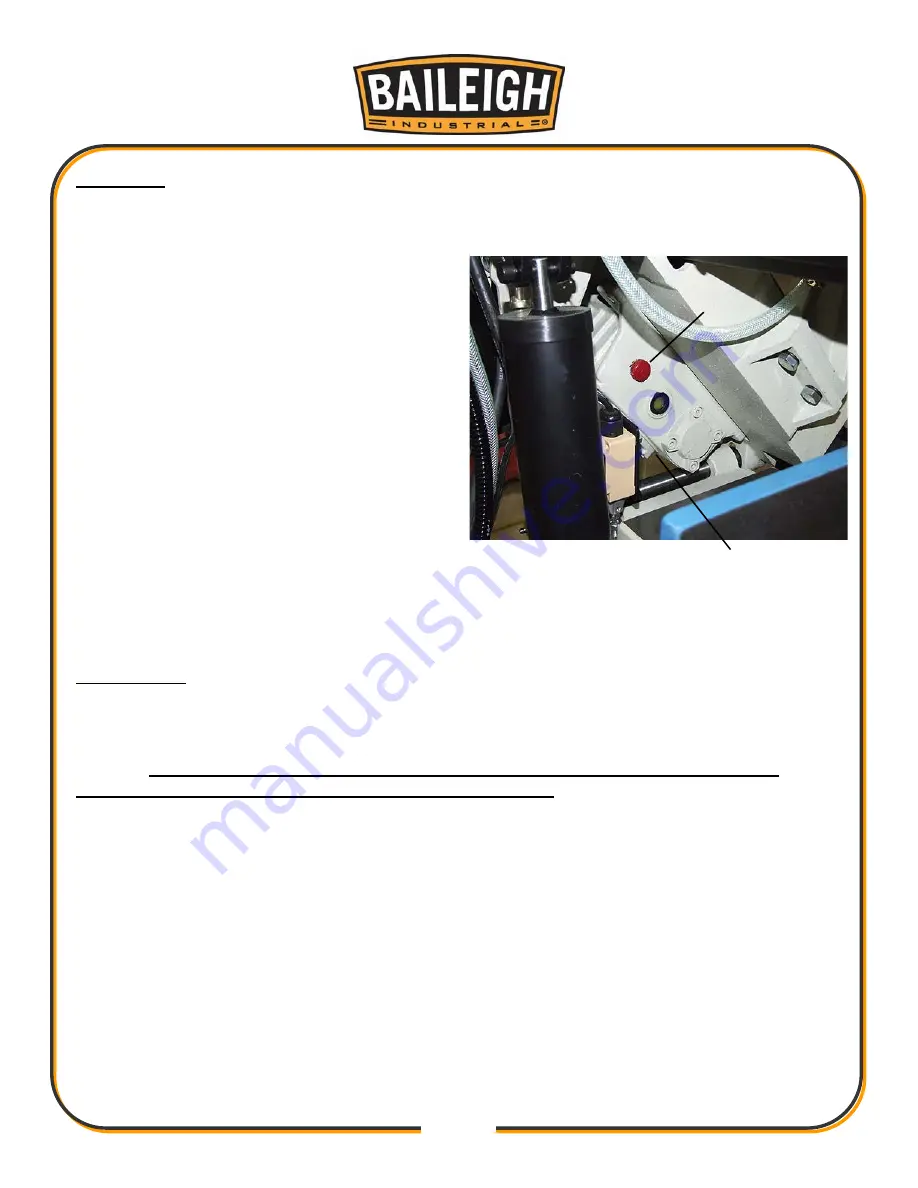

Gear Case

The gear box lubricant should be changed after the first 3 months of operation then changed

every year.

1. Disconnect machine from the power source.

2. Remove drain plug (A) and drain all of the

oil out of the gear box.

3. Replace the drain plug.

4. Remove oil filler plug (B) located

underneath the right blade wheel and fill the

gear box with 1-1/2 pints (.7L) of MOBIL

CYLINDER OIL # 60W or equivalent.

5. Verify that the oil level reaches dot in middle

of sight glass.

6. Replace filler cap.

7. Connect machine to the power source.

8. Use a light machine oil to lubricate all other

moving parts as needed.

Hydraulic Oil

The hydraulic oil is the primary medium for transmitting pressure and also must lubricate the

running parts of the pump.

After installation of the machine and before machine startup, bring the oil level up to 90% of

capacity.

A shortage of hydraulic oil can cause hydraulic system breakdown and

damage to major mechanical parts due to overheating

.

1. Use SHELL BRAND #46 or #68 hydraulic oil or an equivalent with similar specifications.

(Based upon location temperature and availability.)

2. Keep hydraulic reservoir filled to 90% of capacity.

3.

DO NOT

rely totally on the oil gauge as they can sometimes indicate an incorrect level

reading. Do a visual inspection with the oil fill cap removed as well.

4. A shortage of hydraulic oil will cause hydraulic system breakdown to major mechanical

components due to overheating.

5. Change the hydraulic oil every 12 months along with the oil filter.

A

B

Summary of Contents for BS-330SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 21: ...18 18 DESCRIPTION OF MACHINE PARTS A G F E H C I J B K L O P Q D M N...

Page 34: ...31 31...

Page 54: ...51 51 ELECTRICAL SCHEMATIC...

Page 55: ...52 52...

Page 56: ...53 53 Terminal Strip Connections...

Page 57: ...54 54 Switch Designation...

Page 59: ...56 56 HYDRAULIC LAYOUT...

Page 61: ...58 58 PARTS DIAGRAM...

Page 62: ...59 59...

Page 75: ...72 72 NOTES...