SAFETY AND MAINTENANCE MANUAL

1NO0055UK-00

PIAF 10

E

60

DANGER

BEFORE ANY MAINTENANCE, ENSURE

THE

ELECTRIC

SYSTEM

IS

DISCONNECTED FROM THE POWER

SUPPLY.

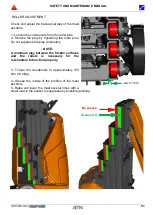

2.1. HYDRAULIC POWER UNIT

DESCRIPTION

The machine is fitted with a power unit consisting of

a pump and a 24V fan-cooled motor. It is located on

the left hand side of the machine.

GENERAL MAINTENANCE

Gear hydraulic pumps deliver reliable performance over a long period of time if operating in a

properly maintained system. This includes using clean oil of correct grade, regular filter

replacement, and frequent inspections of the system components. If a pump fails, it is however

important to determine all the causes and eliminate them to prevent repeated breakdowns.

GENERAL INFORMATION

ABRASIVE WEAR CAUSED BY FINE PARTICLES

Abrasive wear caused by fine particles is the most frequent cause of pump failure. Its symptom is

a gradual reduction in power and therefore of the

machine’s performances. Fine particles or other

foreign bodies circulating through the system cause wear on all components and can be noticed

on pressure plates, housings and shaft bearing areas. Always clean tank caps, funnels and areas

around the filler neck before opening the tank. Cap every disconnected hose, fitting and various

openings.

AERATION OR CAVITATION

Aeration occurs when air mixes with the oil. Air can enter the system through a small suction leak

or by agitation of the oil surface in the tank. Surface agitation occurs when the return oil is dumped

back above the oil level. This can occur when the oil level is too low.

Cavitation is the formation and collapse of vapour bubbles in the oil. This is the result of restricted

pump suction. Cavitation occurs usually when the oil is cold. A pump either cavitating or function

with aerated fluid is noisy and the system functions in a jerky manner.

LACK OF OIL

When a failure is due to lack of oil, deteriorations are usually quick. This kind of breakdown can

occur for two reasons;

(a) the oil level is low in the tank, or (b) there is a leak in the suction hose.

Summary of Contents for PIAF 10E 2018

Page 2: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 2 DISTRIBUTOR STAMP...

Page 8: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 8...

Page 10: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 10...

Page 13: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 13 Chapter I OPERATION AND SAFETY...

Page 14: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 14...

Page 18: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 18...

Page 24: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 24...

Page 42: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 42...

Page 43: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 43 Chapter II MAINTENANCE...

Page 44: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 44...

Page 66: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 66 2 3 HYDRAULIC SCHEMATIC...

Page 78: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 78 3 10 ELECTRIC SCHEMATIC...

Page 79: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 79...

Page 80: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 80 NOTES...

Page 81: ...SAFETY AND MAINTENANCE MANUAL 1NO0055UK 00 PIAF 10E 81 NOTES...