EFD1000 E5 Dual Electronic Flight Instrument (EFI) Install Manual

DOCUMENT # 900-00041-001

PAGE 71-226

REVISION D

© Copyright 2019 Aspen Avionics Inc.

6)

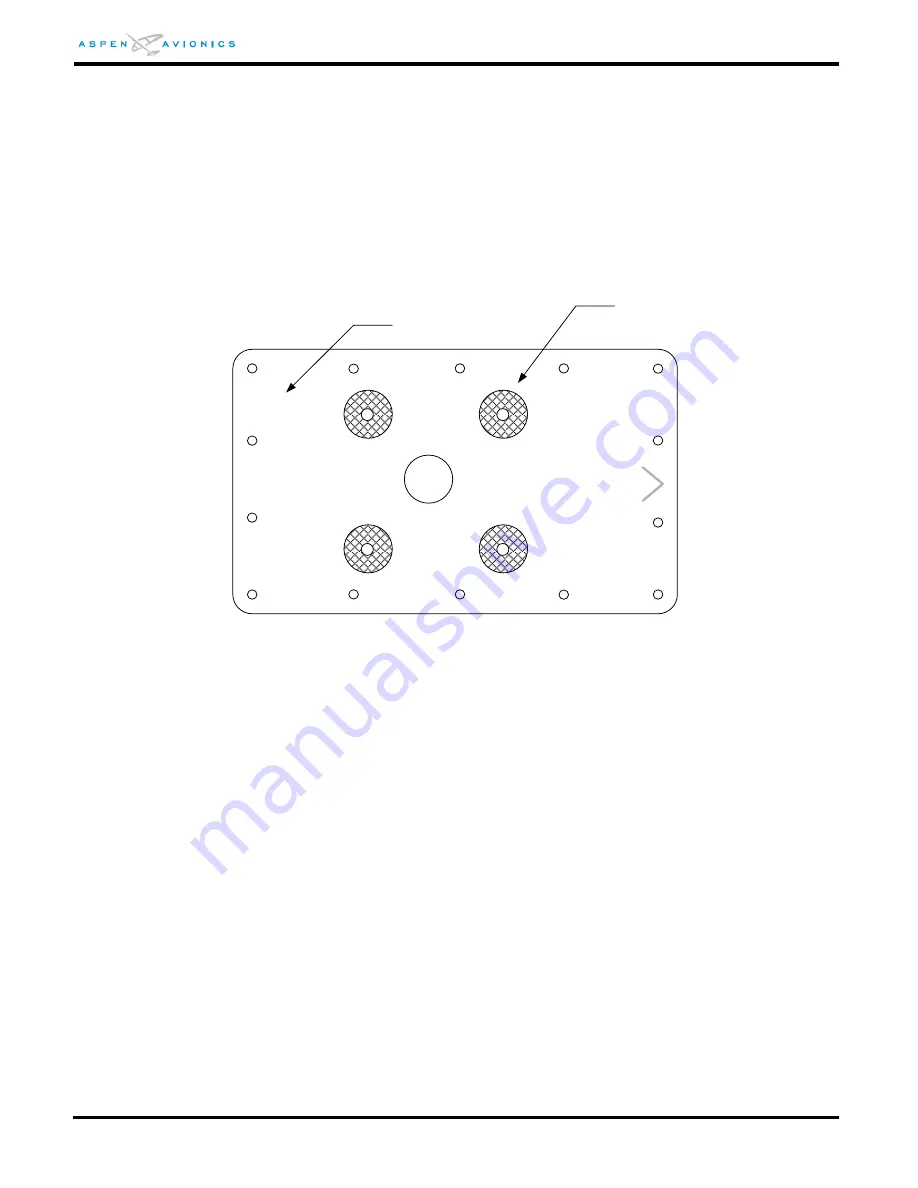

Mask around the four (4) mounting holes the diameter of the mounting washers or

1/2" on the down side of the doubler (see Figure 6-22). Prime that side with epoxy

primer per MIL-P-23377. Do not prime the side that faces the aircraft skin. This

allows for a doubler to aircraft skin bond and mounting washer to doubler bond.

7)

Mark forward direction on doubler because pattern is not symmetrical.

8)

Using the doubler as a template match drill holes in aircraft fuselage at location

determined from Section 6.9.4. Doubler must be aligned to the longitudinal axis of

the aircraft to within ±4º (see Figure 6-14).

Figure 6-20: Masking of Doubler

9)

Remove burrs and break sharp edges on the aircraft skin (0.005” – 0.015”)

10)

Burnish the aircraft skin on the inner surface in the area where the doubler will

mount. Apply Alodine 1201 and do not prime.

11)

The doubler is attached to the inside surface of the aircraft skin with solid rivets.

12)

For aircraft skin less than 0.032 thick install with MS20470AD4 protruding head

rivets.

13)

For aircraft skin thickness of 0.032 install with NAS1097AD4 rivets flush in the

fuselage skin. Carefully control the countersink depth to not knife-edge the

fuselage skin.

14)

For aircraft skin thicknesses 0.040 to 0.050 install with NAS1097AD4 rivets flush in

the fuselage skin.

15)

For aircraft skins 0.063 or thicker install with NAS1097AD5 rivets flush in the

fuselage skin.

F

W

D

Mask four (4) places

Do not primer

Allows for electrical bond

between washer and doubler.

Down side

Primer