MRO 3 & 4 MANUAL

20

98-0140

Rev. F

19b. If the MRO is connected to a small direct-feed loop during disinfection, then the entire

loop must test positive for PAA throughout the loop. Using a fresh test strip at each

dialysis machine water outlet, test the water. The result must be at least 0.5% (250

ppm).

19c. If the small direct-feed loop is using a Product Recovery, the presence of PAA must

test positive at the Chloramine Sample Port at the front of the MRO in addition to each

dialysis machine water outlet. The result must be at least 0.5% (250 ppm).

NOTE:

Water loop systems will vary in size and in volume for each installation. If a small

loop is to be disinfected along with the MRO, then PAA must be drawn into the

MRO using only the disinfection function, pumped into the loop by the MRO through

the PRODUCT WATER hose connection. After each container of PAA solution is

drawn into the MRO, then the MRO must be stopped without delay, and each water

outlet must be tested for PAA at the minimum amount. Continuing to run the MRO

after all the PAA solution is drawn out of the PAA container will only result with

diluting the strength of the PAA, which reduces the disinfecting capability.

If the PAA at each water outlet has not been found to be positive at the minimum

required amount, another container must be drawn into MRO, and into the loop,

until the minimum strength is tested and verified using a PAA test strip. If the

minimum required level of PAA cannot be achieved after a reasonable number of

volumes from the PAA container (usually around 5, or determined by your facility

manager), refer to the “large” loop disinfection procedure outlined in the following

section.

UNTIL THE PAA IS FOUND TO BE POSITIVE AT EACH WATER OUTLET TEST

POINT AT 0.5% MINIMUM, THE LOOP SYSTEM CANNOT BE RELIABLY

DISINFECTED.

20.

Label the MRO with appropriate WARNING signs (Example: “DO NOT USE /

CONTAINS DISINFECTANT”).

21.

To assure that the MRO will not be accidently used for dialysis, leave the MRO in the

DISINFECT ENABLED mode, and allow the PAA solution to soak for 60 minutes

within the MRO, and in the loop (if connected to one).

WARNING:

Soaking longer than 12 hours may cause damage to the membrane.

22.

Record the Start and Stop times on the Log to have a record of how long the

membrane soaked in PAA disinfecting solution.

23.

Flush the residual PAA from the disinfectant draw plumbing.

a.

Rinse and fill the PAA Container to the red line with dechlorinated water from the

Incoming Tap Water Test Port and connect the PAA tubing to the PAA

connection on the front of the MRO.

Summary of Contents for MRO3

Page 8: ...MRO 3 4 MANUAL 5 98 0140 Rev F SECTION 3 COMPONENTS AND SCHEMATICS 3 1 EXTERNAL FRONT VIEW...

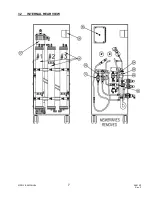

Page 10: ...MRO 3 4 MANUAL 7 98 0140 Rev F 3 2 INTERNAL REAR VIEW...

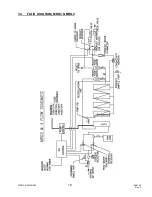

Page 12: ...MRO 3 4 MANUAL 9 98 0140 Rev F 3 3 ELECTRICAL DIAGRAM MRO3 MRO4...

Page 13: ...MRO 3 4 MANUAL 10 98 0140 Rev F 3 4 FLUID DIAGRAM MRO3 MRO4...

Page 34: ...MRO 3 4 MANUAL 31 98 0140 Rev F FIGURE 6 2...

Page 35: ...MRO 3 4 MANUAL 32 98 0140 Rev F FIGURE 6 3...

Page 52: ...MRO 3 4 MANUAL 49 98 0140 Rev F SECTION 11 MRO3 4 SPARE PARTS LISTING...