MRO 3 & 4 MANUAL

11

98-0140

Rev. F

SECTION 4 MRO STARTUP & OPERATION

4.1

CAUTION

NOTE:

This entire Operations Manual should be read before operating or servicing

the MRO system. The Operations Manual should then be kept near the

system and used as a reference and troubleshooting guide.

WARNING: This Reverse Osmosis System (RO) contains a preservative solution to

prevent microbiological growth and freezing. Discard all product water for

at least two hours of operation before placing the RO in service.

CAUTION:

No person should attempt to operate or service the MRO without prior

authorization or instruction from your medical facility director.

The following operating or water supply conditions could cause an accident or the MRO

system to fail:

1.

The electrical source for the controller must be single phase, 3-conductor type

provided with a hospital grade receptacle and a ground fault interrupter (GFI) at 115V,

60Hz. The proper polarity and ground integrity must be initially checked and thereafter

maintained. Failure to do so may result in electrical shock to the operator or patient. It

is suggested that the MRO be placed on an electrical supply with emergency backup.

2.

The MRO must only be plugged directly into a GFI receptacle. It must not be plugged

into an extension cord or power strip that could cause low amperage.

3. All local plumbing and electrical requirements should be met.

To avoid electrical shock, always unplug the MRO system before opening

the access panel or the face of the electrical controller.

4.

Incoming water should be between 41° F and 90° F (5° C and 33° C). It is not

recommended to use water at temperatures below 41° F (5° C) because it will reduce

membrane performance significantly. Use only the cold water supply unless using an

automatic blending valve to get 77° F (25° C) water. Never use water warmer than 90°

F (33° C).

5.

Water with silt density index (SDI) above 5 SDI will foul the membrane.

6.

The MRO system may be equipped with a pretreatment system to remove chlorine

and chloramines. It is important to test for chlorine and chloramines at the

CHLORAMINES SAMPLE PORT before each use of the system. Chlorine will

deteriorate the membrane and cause system failure. It is recommended to use a Total

Chlorine test kit, such as IBT Water Check 2 Low Level Chlorine/Chloramines Test

Strips (P/N 97CM20201).

7.

Incoming tap water pH should be within EPA National Secondary Drinking Water

Regulations of 6.5 - 8.5. Incoming tap water with pH higher or lower than the

regulation will cause higher conductivity in the product water. If the water changes

drastically, the membrane will be harder to clean. Periodically check the pH of the

incoming tap water to verify that it is within the specified range (IBT pH

Water/Bicarbonate/Dialysate Test Strips P/N 97PH20901).

Summary of Contents for MRO3

Page 8: ...MRO 3 4 MANUAL 5 98 0140 Rev F SECTION 3 COMPONENTS AND SCHEMATICS 3 1 EXTERNAL FRONT VIEW...

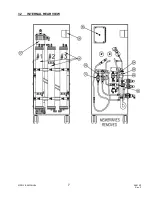

Page 10: ...MRO 3 4 MANUAL 7 98 0140 Rev F 3 2 INTERNAL REAR VIEW...

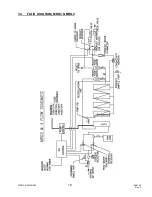

Page 12: ...MRO 3 4 MANUAL 9 98 0140 Rev F 3 3 ELECTRICAL DIAGRAM MRO3 MRO4...

Page 13: ...MRO 3 4 MANUAL 10 98 0140 Rev F 3 4 FLUID DIAGRAM MRO3 MRO4...

Page 34: ...MRO 3 4 MANUAL 31 98 0140 Rev F FIGURE 6 2...

Page 35: ...MRO 3 4 MANUAL 32 98 0140 Rev F FIGURE 6 3...

Page 52: ...MRO 3 4 MANUAL 49 98 0140 Rev F SECTION 11 MRO3 4 SPARE PARTS LISTING...