MRO 3 & 4 MANUAL

19

98-0140

Rev. F

15.

Press and hold the ENTER key to turn on the Disinfect Draw function and THE

DISPLAY WILL READ

DISINFECT ENABLED DRAW

.

16.

Adjust the REJECT flow control knob so that the PAA will be drawn into the MRO in

about 2 minutes. (Figure 5.1) The REJECT flow amount will have to be determined

the first time the PAA is drawn in, and noted so that it will empty the container in about

2 minutes.

17a. Continue holding the ENTER key until the PAA container is empty, then immediately

release the ENTER key.

17b. If disinfecting the MRO while connected to a small direct-feed loop:

Draw a complete PAA container into the MRO (with the REJECT flow amount

adjusted as needed described in step 12).

Release the ENTER key, then refill the PAA container, reconnect the PAA

container to the MRO, press & hold the ENTER key, and draw the 2

nd

PAA

container into the MRO.

When the 2

nd

PAA container’s contents reaches the blue line (or a level

approximately 2” from the bottom) on the PAA Container, continue holding the

ENTER key, but be prepared to release the ENTER key when the PAA

container is emptied (Approximately ¼” of the solution will remain in the bottom

of the plastic container). Avoid sucking air into the system.

NOTE: The ENTER key must be held until all the PAA is drawn into the MRO.

a. Avoid stopping and starting the disinfect function which may cause a thermal

overload of the MRO pump.

b. Releasing the ENTER key may cause the system to lose its prime preventing all of

the disinfectant from being drawn into the MRO.

c. Approximately ¼” of the solution will remain in the bottom of the PAA container.

This is normal and may be emptied down the drain after the entire process is

complete.

18.

Record on the Start-Up Log that this step was performed.

19a. The MRO (if not connected to a loop) should be filled with PAA disinfecting solution.

To ensure that PAA solution has been pumped through the MRO, use Peraacid test

strips (P/N 97hp20401):

a. Using a test strip, test the water the REJECT WATER TO DRAIN hose, the

result must be at least 1% (500 ppm).

b. Use another test strip at the PRODUCT WATER hose, the result must be at

least 0.5% (250 ppm).

Summary of Contents for MRO3

Page 8: ...MRO 3 4 MANUAL 5 98 0140 Rev F SECTION 3 COMPONENTS AND SCHEMATICS 3 1 EXTERNAL FRONT VIEW...

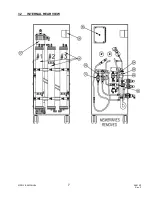

Page 10: ...MRO 3 4 MANUAL 7 98 0140 Rev F 3 2 INTERNAL REAR VIEW...

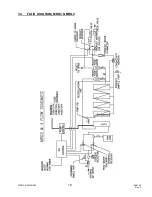

Page 12: ...MRO 3 4 MANUAL 9 98 0140 Rev F 3 3 ELECTRICAL DIAGRAM MRO3 MRO4...

Page 13: ...MRO 3 4 MANUAL 10 98 0140 Rev F 3 4 FLUID DIAGRAM MRO3 MRO4...

Page 34: ...MRO 3 4 MANUAL 31 98 0140 Rev F FIGURE 6 2...

Page 35: ...MRO 3 4 MANUAL 32 98 0140 Rev F FIGURE 6 3...

Page 52: ...MRO 3 4 MANUAL 49 98 0140 Rev F SECTION 11 MRO3 4 SPARE PARTS LISTING...