Alvarado Manufacturing Company, Inc.

12660 Colony Street, Chino, CA 91710

Phone: +1 (909) 591-8431

Fax: +1 (909) 628-1403

[email protected]

www.alvaradomfg.com

PUD3448R2-1

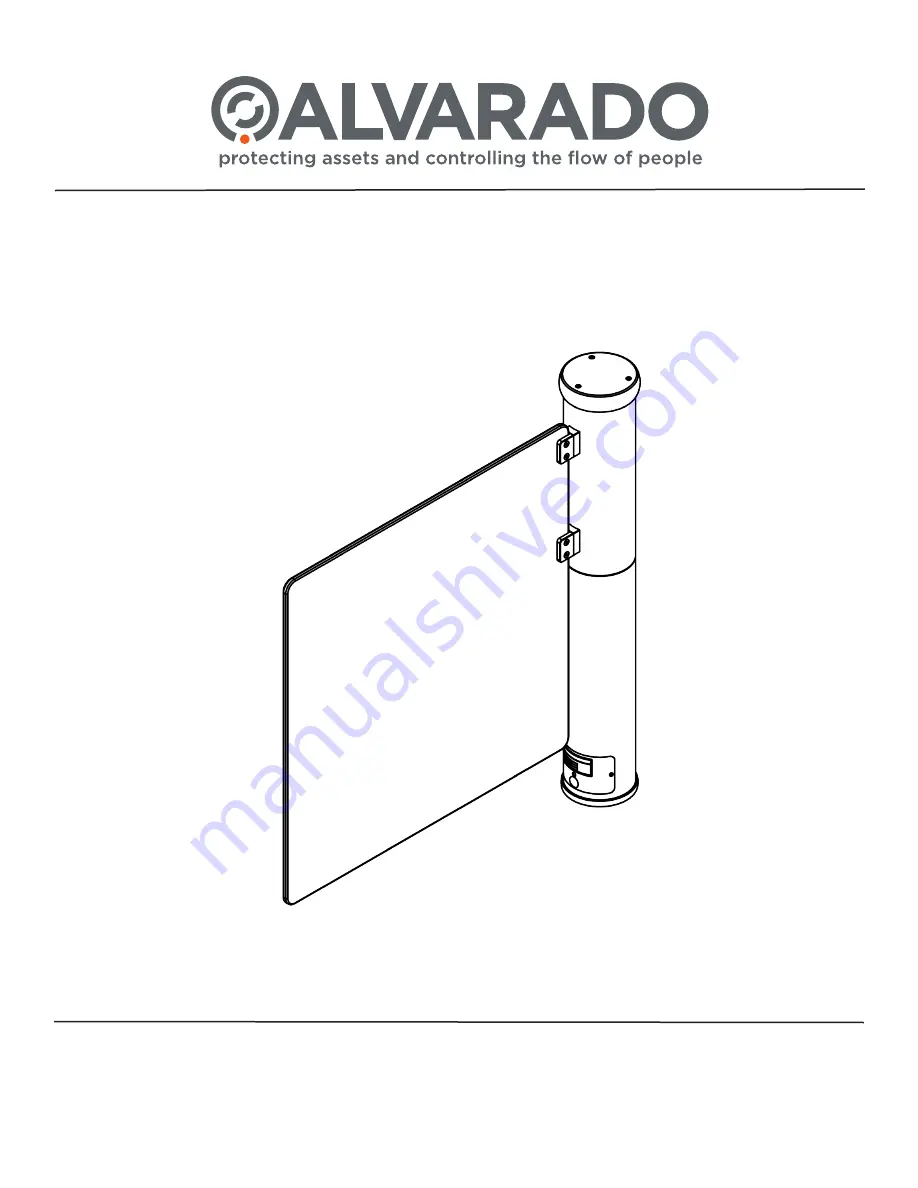

SW1000/SW1000T

Motorized Pedestrian Security Gate

Installation and Operation Instructions