41

Subject to technical amendments without prior notice | 83055400iUK – 2.1 | ait-deutschland GmbH

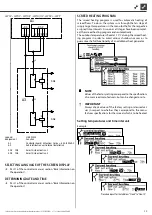

No.

Display

Description

Remedy

762

Sensor compressor intake

Tü sensor error (compressor intake).

Check sensor, replace if necessary.

763

Sensor evaporator intake

Tü1 sensor error (evaporator intake).

Check sensor, replace if necessary.

764

Sensor compressor heater

Sensor error compressor heater.

Check sensor, replace if necessary.

765

Overheating

Overheating longer than 5 minutes below 2K.

When switching on for the first time, check

rotary field, otherwise phone customer

service.

766

compressor's functional

range

Operation for 5 minutes outside the compressor's functional

range.

Check rotary field.

767

STB E-Rod

STB of the heating element has been activated.

Check the heating element and press the

fuse back in.

768

Flow monitoring

Insufficient flow in defrost cycle.

Check hydraulics, check pump, check flow.

769

Pump control

After 10 sec compressor runtime excessively low flow.

Check PWM cable, check pump.

770

Low superheat

Overheating lies below the limit value for a lengthy period.

Check the temperature sensor, pressure

sensor and expansion valve.

771

High superheat

Overheating lies below the limit value for a lengthy period.

Check the temperature sensor, pressure

sensor, fill quantity and expansion valve.

775

SEC EVI valve

Electronic expansion valve is no longer recognised by the

control in the EVI circuit

Check the expansion valve, connection

cable and if applicable the SEC board

776

limit of application-CP

Compressor operates outside its use limits for a lengthy period. Check the thermodynamics.

777

Expansion valve

Electronic expansion valve is defective.

Check the expansion valve, connection

cable and if applicable the SEC board.

778

Low pressure sensor

Low-pressure sensor is defective.

Check the sensor, connector and

connection cable.

779

High pressure sensor

High-pressure sensor is defective.

Check the sensor, connector and

connection cable.

780

EVI sensor

EVI sensor is defective.

Check the sensor, connector and

connection cable.

781

Liquid temp. sensor before

EXV

Liquid temperature sensor upstream of the ex-valve is

defective.

Check the sensor, connector and

connection cable.

782

Suction gas EVI temp.

sensor

Suction gas EVI temperature sensor is defective.

Check the sensor, connector and

connection cable.

783

Communication SEC

board – Inverter

Connection between the SEC board and the inverter is

disrupted.

Check the connection cable, interference

suppression capacitors and wiring.

784

VSS lockdown

Inverter is blocked.

Disconnect the complete system from the

power supply for 2 minutes.

If it occurs again, check the inverter and

compressor.

785

SEC-Board defective

Error found in the SEC board.

Replace the SEC board.

786

Communication SEC

board – Inverter

Connection between SEC board and HZ/IO is disrupted by the

SEC board.

Check the HZ/IO – SEC board wiring.

787

VD alert

Compressor signals faults.

Acknowledge fault.

If an error occurs repeatedly, phone the

authorised service personnel (customer

service).

788

Major VSS fault

Fault in the inverter.

Check the inverter.

789

LIN/Encoding not found

Control unit unable to find coding. Either the LIN connection is

interrupted or the coding resistor is not detected.

Check the connection cable LIN / coding

resistor.

790

Major VSS fault

Fault in the power supply of the inverter / compressor.

Check the wiring, inverter and compressor.

791

ModBus connection lost

Inverter

The control panel has no ModBus communication with the

inverter for at least 10 seconds or 10 communication packets

to the inverter were lost. Reset automatically.

Check the Modbus wiring of inverter.

792

LIN-connection lost

Unable to find a master board or any configuration.

Check the coding connector on the LIN

board(s).

793

Inverter Temperature

Temperature sensor fault in the inverter. Internal inverter

temperature too high at least 5x within 24 h.

Fault acknowledges itself.

794

Overvoltage

Overvoltage on inverter.

Check the inverter voltage supply.