Agilent 1260 Infinity II Preparative Autosampler User Manual

185

Maintenance

9

Exchange the Wash Port Assembly

15

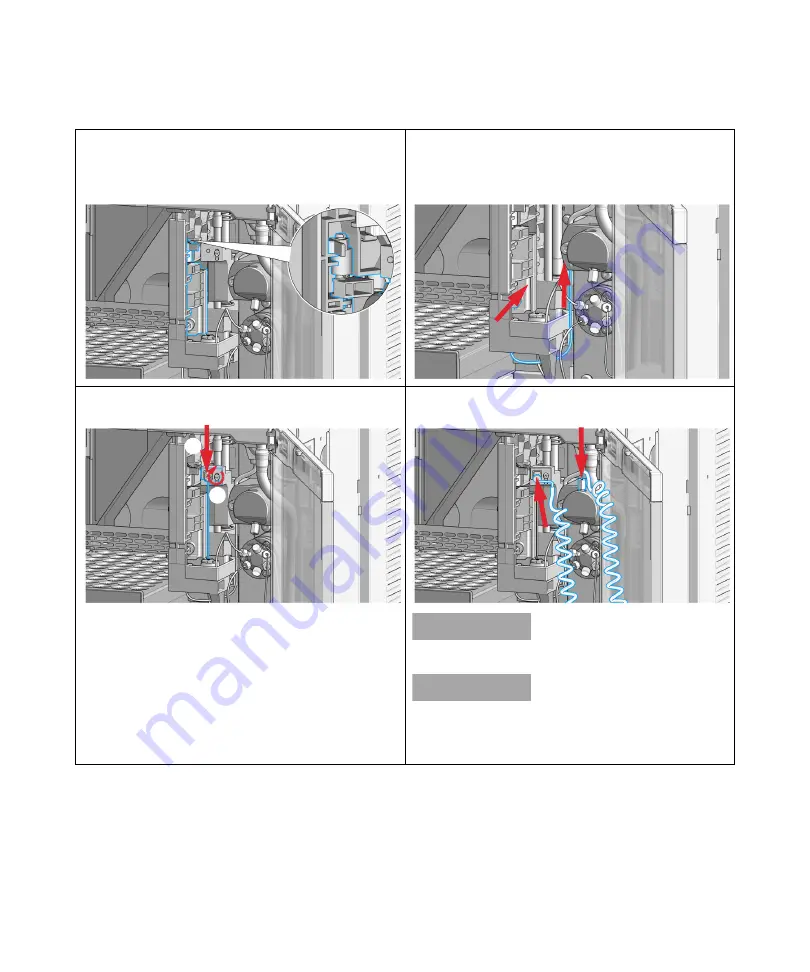

Reinstall the new wash port assembly by mounting the

flapper into the housing of the needle station. The pin

must be latched into the housing. Check the movement

of the flapper.

16

Install and reconnect the wash tubing to the peristaltic

pump.

17

Insert the needle (1). Align the needle in the seat, then

tighten the screw firmly (2).

18

Reconnect the sample-loop to the needle.

N O T E

Do not overtighten the fitting!

N O T E

Incorrect positioning and installation of the

needle/loop connection can result in damaging and

breaking the sample loop.

1

2