43

8.4

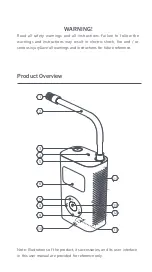

High pressure compressor Pilot Valve

50a

MTG

thread

Proceed with the following instructions while

compressor is running (Fig. 50a):

1.

Loosen locknut (4) and back off several

turns. Do not turn differential adjuster (3).

2.

Check reading on the tank pressure gauge

at 12 bar (170 psig). Turn the regulation

screw clockwise to increase pressure or

counterclockwise to decrease pressure.

3.

After pressure is set, tighten locknut (4). Be

careful not to move the nut of threaded

cap (1).

Proceeding with the following instructions while compressor is running:

1. Loosen locknut (2) and back off several turns.

2. Controllare il manometro sul serbatoio.

Check reading on the tank pressure gauge. Set the pressure to 2 bar ( 30 psi) differential (unload at

12 bar - 170 psi, and reload at 10 bar -140 psi). Turn nut (3) clockwise to increase differential pressure

or counterclockwise to decrease differential pressure.

3. After pressure is set, tighten locknut (2). Be careful not to move the nut of threaded

cap (3).

Pressure adjustment

8.4.1

Differential pressure adjustment

8.4.2

SENSING TUBE FROM

AIR RECEIVER

ACTUATING TUBE TO

HEAD UNLOADER

Start up

Summary of Contents for MCH 14 TECH NITROX SERIES

Page 31: ...31 Installation 3 Pass the pipe through the hole located in the rear guard Fig 29 30 28 29 ...

Page 80: ...80 Troubleshooting 12 1 1 Low pressure compressor ...

Page 85: ...85 Compression diagram High pressure compressor only air Machine diagrams 14 2 ...

Page 86: ...86 Machine diagrams 14 3 Electrical diagram ...

Page 87: ...87 Machine diagrams ...

Page 104: ...104 Pulley Crankcase and cylinder Low pressure compressor Spare parts ...

Page 105: ...105 Piston rod unit Low pressure compressor Spare parts ...

Page 106: ...106 Cylinder Valve and Filter unit Low pressure compressor Spare parts ...

Page 107: ...107 Pump unit Low pressure compressor Spare parts ...