GF-135

Esteem 399 Low NOx Boiler

Chapter 5

OMM-0089_0A

Installation, Operation & Maintenance Manual

Boiler Piping

Page

36

of

188

AERCO International, Inc.

•

100 Oritani Dr.

•

Blauvelt, NY 10913

OMM-0089_0A

MC1 06/19/14

Ph.: 800-526-0288

5.16 SYSTEM PIPING—SPECIAL APPLICATIONS

If the boiler is used in conjunction with a chilled water/medium system, the boiler and chiller

must be piped in parallel. Install flow/check valves to prevent the chilled medium from entering

into the boiler.

If the boiler is used to supply hot water to the heating coils of an air handler where they may

be exposed to chilled air circulation, install flow/check valves or other automatic means to

prevent gravity circulation of the boiler water during cooling cycles.

5.17 SYSTEM PIPING—MULTIPLE UNITS INSTALLATION

Use a balanced manifold system as the primary / secondary connection to the space heating

piping as shown in Figure 5-9

.

Maintain a minimum of 6 inches [153 mm] of clearance between units to allow for servicing.

Refer to Figure 5-3 and Figure 5-4

to install air separator and expansion tank.

For the space heating piping refer to the applications mentioned in this manual or use

recognized design methods.

NOTE

The boiler system piping shown must be a “closed” system to

avoid any contamination and potential failure of any components

in the system.

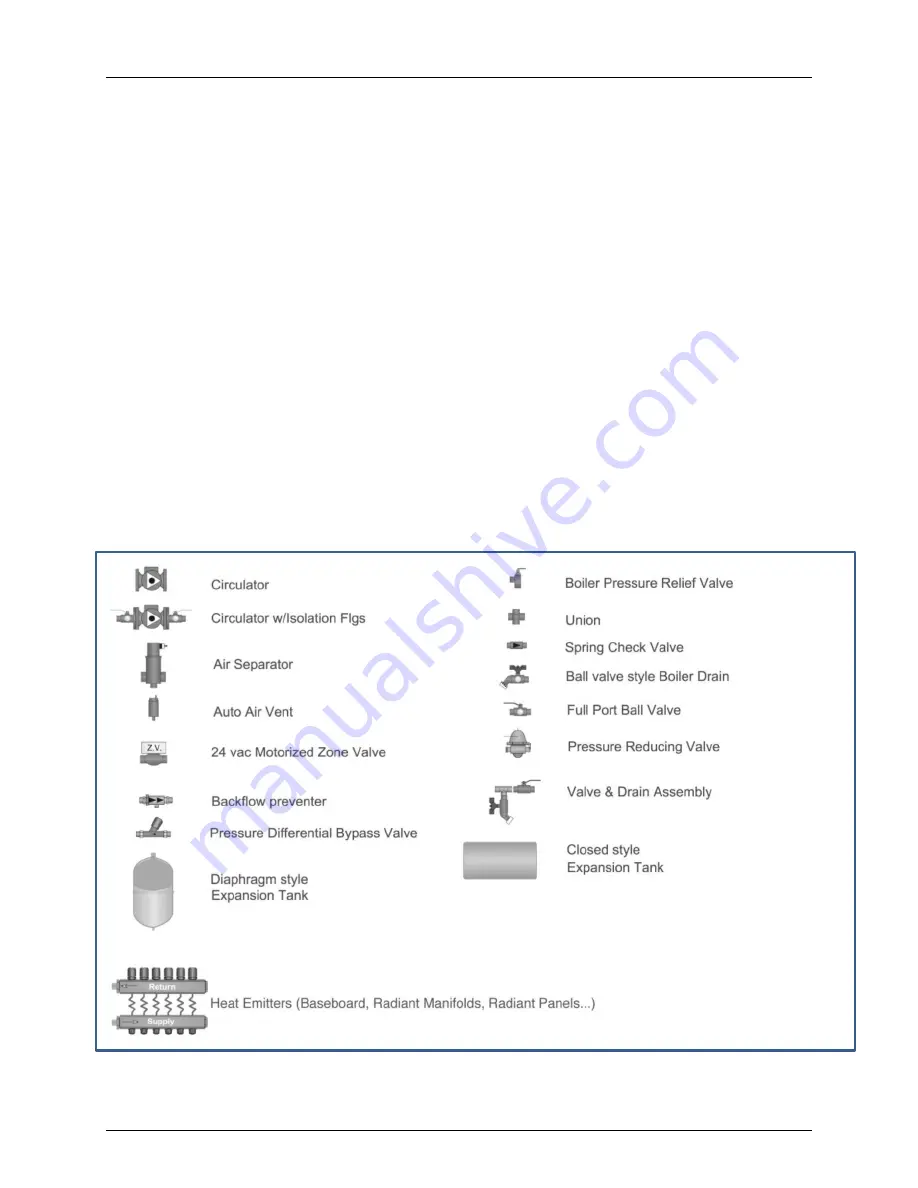

Figure 5-2: Piping Diagram Component Legend