Example # 2 - Tracking an edge:

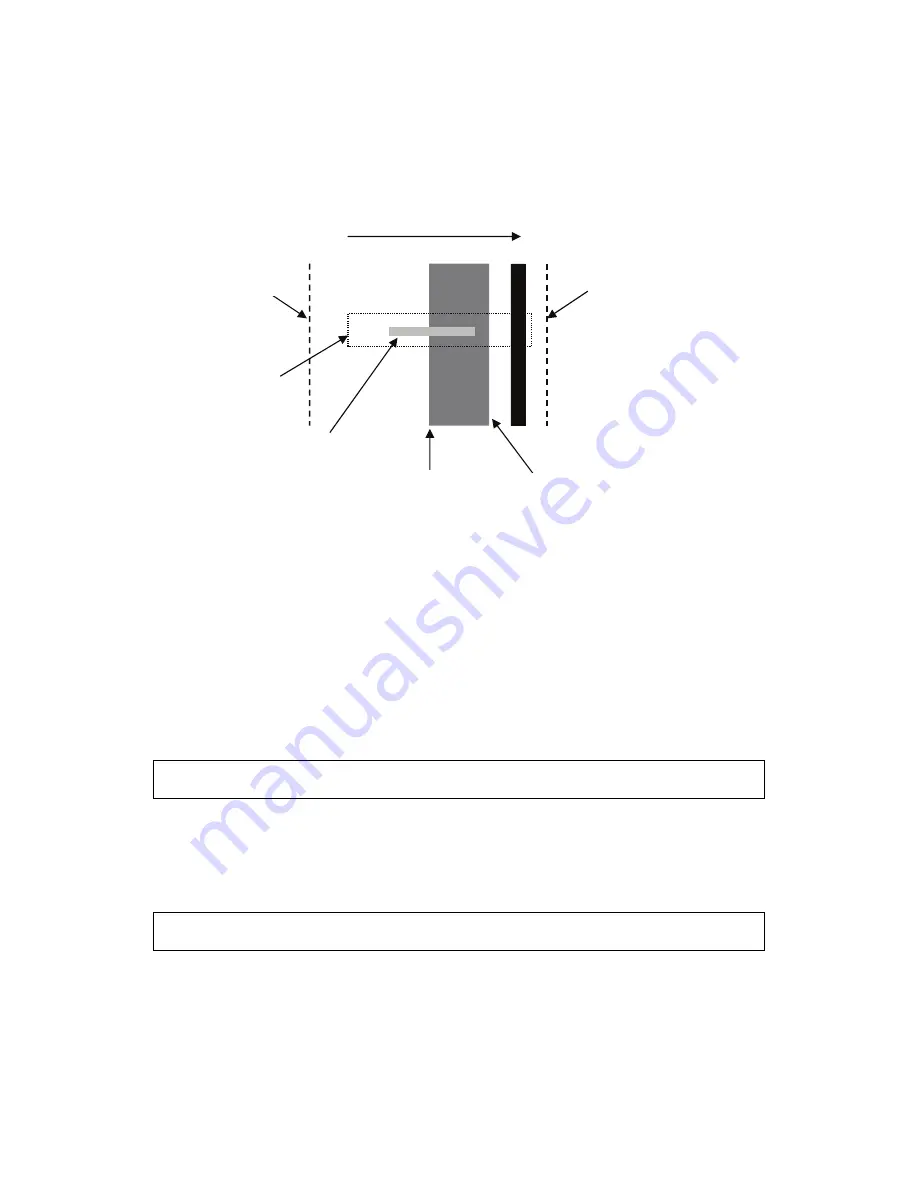

1) Suppose you have a narrow black line and a wide yellow stripe printed on silver metallized

film, as shown below:

2) Now, let’s assume you want to track the left edge of the yellow stripe. Since there will

probably be several edges in the sensor’s field of view you will need to indicate which edge

you want the sensor to track.

Right edge of web

Scan direction (Left-to-Right)

Selection window

Left edge of web

Registration edge

Sensor’s field of view

0.625” [15.9mm] wide)

Yellow stripe

(

a) Position the sensor so that it is approximately centered over the left edge of the yellow

stripe.

b) Select the Calibration parameter and press ENTER to start the auto-calibration

procedure.

c) When the “Select line/edge” message appears, adjust the position and width of the

selection window so that it straddles the left edge of the yellow stripe and covers roughly

equal amounts of the stripe and metallized area to its left. Make sure the window

does

not

touch the right edge of the stripe. Use the DOWN key to adjust position and the UP

key to adjust size.

Note:

It may not be necessary to adjust the selection window if there is only one edge in

the sensor’s field of view and the sensor has been centered over it.

d) As you adjust the window size and position, the sensor will continuously analyze your

selection and pick the best parameter settings to track the edge you selected. If it can

reliably track this edge it will place an indicator dot directly under it.

e) If the indicator dot is not visible or is in the wrong place, adjust the selection window size

and position until the indicator appears under the desired edge.

Tip:

To exit from the auto-calibration procedure without changing any settings, press the

UP key repeatedly until the “Exit?” message appears, then press ENTER.

3) When the indicator dot is under the edge you want to track, press the ENTER key to

complete the auto-calibration. The sensor will then store the new parameter values in the

current Job Profile’s memory. For the material used in this example the parameters will be set

to the following values:

AccuBeam 3 Digital Line Guide Sensor

68

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Summary of Contents for MICRO 4000 NET

Page 3: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 141: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 142: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 143: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 144: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 145: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 146: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 147: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 148: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 149: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 150: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 151: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 152: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 153: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 154: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...