Operating and Maintenance Instructions

Inspection intervals

1HSB435409-100 en1

9

Condition of circuit-breaker during work:

a1)

Circuit-breaker in service.

b1)

Closing springs unloaded, circuit-breaker open, disconnected and earthed. If

thermovision measurement is included, it shall be done at normal load before

the circuit-breaker is disconnected.

c1)

Closing springs unloaded, circuit-breaker open, disconnected and earthed.

Poles/Breaking units dismounted and transported to workshop.

d1)

Closing springs unloaded, circuit-breaker open, disconnected and earthed.

Complete circuit-breaker including operating mechanism transported to

workshop.

Competence requirements:

a2)

Substation personnel with no special training.

b2)

Personnel authorised by ABB to carry out assembly, commissioning and

maintenance work.

c2)

Personnel authorised by ABB to carry out assembly, commissioning and

maintenance work. Support from ABB may be necessary in certain cases.

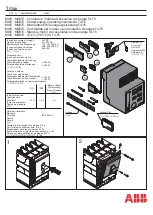

3.2 Maintenance category A

To be inspected

Inspection interval

Measures / Instructions /

Tools

1.

Ocular inspection

1-2 years

Check external cleanliness, heater

element function, gas pressure, valves

and drainage holes.

No special tools needed.

See

Chapter 2.1.3

and

Chapter 2.1.4

and 1HSB515409-100 for BLG 1002A

or 1HSB535409-100 for BLK 222.

Summary of Contents for SF6 LTB 245E1 BLG 1002A

Page 1: ...Product Manual 1HSB435416 2 en Rev 1 LTB 245E1 BLG 1002A 3 pole operation ...

Page 92: ...ABB Switchgear SF6 Circuit Breaker Circuit breakers HPL and LTB 1HSB445409 1 en0 Lubricants ...

Page 198: ......

Page 199: ......

Page 209: ......

Page 210: ......