52

MOU NTI NG A N D OPE R ATI ON M A N UA L

I N D O O R A I R S W I TC H - D I S CO N N EC TO R , N A L /N A L F/ V R

_

WARNING!

In case of A mechanism pay extreme

caution during adjusting the position of

the main contacts because this kind of

mechanism can unexpectedly open the

switchdisconnector.

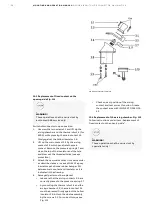

1. Switch with A-mechanism. On delivery the

draw bars (1.1) are detached,

a) test by hand that each arcing knife (1.2)

moves freely in the arc chamber (1.3),

b) pull the main contacts by hand (1.4) to

open position, see Fig.105. Attach the draw

bars to the main shaft (1.5) by the eccentric

bolt (1.6), and secure with washer and circlip.

2. Switch with K-mechanism. On delivery the

draw bars are connected.

3. Before operating the switch, check that the

surfaces of the main contacts are covered by

contact grease in the contact area. The

grease type Isoflex Topas NCA 52 must be

used if additional grease is required.

4. Operate the switch several times.

5. Check the main contact position at closed

switch- disconnector.

6. After all adjustments this position must be in

accordance with adjusting specification

shown on Fig. 106- in case of fixed contact

with a height of approximately 38 mm, main

contact in closed position should be between

two extreme positions: 2 mm above and 4

mm below the fixed contact. In case of fixed

contact with a height of approximately 46

mm, main contact in closed position should

not be below the fixed contact more than 10

mm while not extending below the lower

edge of the fixed contact. If this position is

different then it must be adjusted by the

eccentric bolt (see Fig.110). To do this,

change positions of eccentric bolts placed on

the shaft arms (unscrew the M10 nut by

wrench first to make possible rotation of

eccentric bolt, rotate the eccentric bolt by

second flat wrench, then tighten the nut with

32 [Nm] +/-10% torque) to achieve proper

position of main knives.