60

MOU NTI NG A N D OPE R ATI ON M A N UA L

I N D O O R A I R S W I TC H - D I S CO N N EC TO R , N A L /N A L F/ V R

1 / 1

1:5

A3

Sheet No.

Format

Language

Scale

Subtitle

Type

Derived from

Name

Date

Location

Revision

Drawn

Checked

Approved

EC No.

EN

Drawing status

Title

Drawing No.

Responsible

ABB Switzerland Ltd

Weight

Material

f

m

c

v

H

L

K

PROPRIETARY AND SECRET INFORMATION The information contained in this document has to be kept stric

tly confidential.

Any unauthorized use, reproduction, distribution or disclosure

to third parties

is strictly forbidden. ABB reserves all rights regarding Intell

ectual Property Rights.

Thread Quality Tolerance

"6g-6H" ISO 965

ISO 2768 T.1 Lengths and Angle

ISO 2768 T.2 Geometrical Tolerances

Surface

Surface code

Coord. punching N.C.Mach.

and unfold JS11

Standard Tolerances for Machining and Forming

© Copyright

ABB. All rights reserved.

2016

5

4

3

2

1

H

G

F

D

C

B

A

H

G

F

E

C

B

A

5

4

3

2

1

Group Technology Management

M. Mańkowski

PL-PSY

05.03.2020

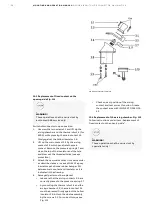

21.5 Replacement of the piston with piston rod.

Fig. 121

1. Remove spring mechanism before starting (if

a mechanism is installed).

2. Close the switch-disconnector.

3. Disconnect the lower part of draw bar from

the main shaft.

4. Disconnect the piston rod from the operating

shaft and piston can be taken out.

5. New piston is installed the reverse way.

6. Connect the drawbar to the eccentric bolt on

the main shaft."

—

121 Replacement of the piston with piston rod.

—

122 Tightening torque for screws NAL/VR 36-40,5

_

WARNING!

These operations shall be carried out by

authorised ABB service only!

_

Note:

Piston and cylinder MUST NOT be

greased or lubricated.

_

Note:

A certain degree of adjustment can

be made by moving the hollow insulator.

21.4 Replacement of the hollow insulator. Fig.

120

1. Disconnect the switch-disconnector.

2. The spring mechanism is removed from the

frame.

3. All draw bars are detached from the crank

arm of the operating shaft, see Fig.116.

4. Turn the operating shaft to one side.

5. Disconnect the piston rod from the operating

shaft and piston can be taken out.

6. Undo the mounting screws on insulator.

7. The hollow insulator is attached to the frame

by 4 screws M10 (spanner-gap 17). New

insulator is mounted. If contact blocks and

arc extinguishing chambers are to be used

again, these must be mounted to the

insulator BEFORE the insulator is fitted to the

switch frame.

8. Add spring mechanism and connect all draw

bars to the crank arms as described in

paragraph “Hollow insulator with arcing

chamber”.

9. The position of the insulator is checked and

adjusted as described in paragraph “Hollow

insulator with arcing chamber”.

—

120 Replacement of the hollow insulator.

_

WARNING!

These operations shall be carried out by

authorised ABB service only!

15 Nm

11

9

1

2

3

8

6

4

10

7

5

40 Nm

12