Planning the electrical installation 45

Selecting the power cables

General rules

Dimension the supply (input power) and motor cables

according to local

regulations

.

• The cable must be able to carry the drive load current. See the chapter

for the rated currents.

• The cable must be rated for at least 70

°

C maximum permissible temperature of

conductor in continuous use. For UL installations use 75 °C copper wiring only.

• The conductivity of the PE conductor must be equal to that of a phase conductor

(i.e. same cross-sectional area).

• 600 VAC cable is accepted for up to 500 VAC.

• Refer to the chapter

for EMC requirements.

Symmetrical shielded motor cable must be used (see the figure below) to meet the

EMC requirements of the CE mark.

A four-conductor system is allowed for input cabling, but shielded symmetrical cable

is recommended. Compared to a four-conductor system, the use of symmetrical

shielded cable reduces electromagnetic emission of the whole drive system as well

as motor bearing currents and wear.

The motor cable and its PE pigtail (twisted shield) must be kept as short as possible

in order to reduce electromagnetic emission.

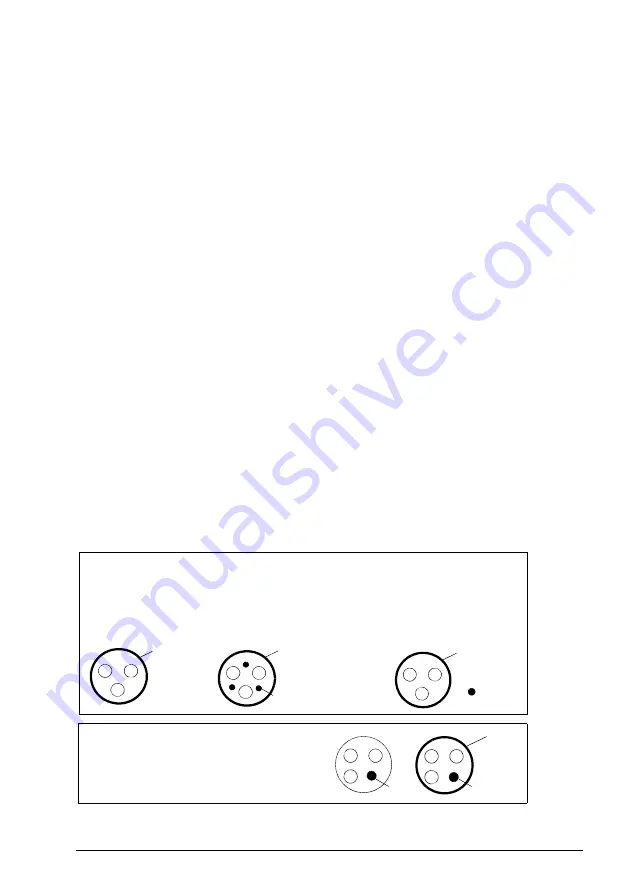

Alternative power cable types

Power cable types that can be used with the drive are represented below.

Symmetrical shielded cable: three phase conductors

and a concentric or otherwise symmetrically

constructed PE conductor, and a shield

Motor cable

(also recommended for supply cabling)

PE conductor

and shield

Shield

Shield

Note:

A separate PE conductor is

required if the conductivity of the

cable shield is not sufficient for the

purpose.

A four-conductor system: three phase conductors

and a protective conductor.

Shield

PE

PE

Allowed for supply cabling

PE

PE

Summary of Contents for MicroFlex e190

Page 1: ...ABB motion control User s manual MicroFlex e190 servo drive ...

Page 4: ......

Page 12: ...12 Table of contents ...

Page 26: ...26 Introduction to the manual ...

Page 90: ...90 Electrical installation input output ...

Page 146: ...146 Maintenance ...

Page 178: ...178 Resistor braking ...

Page 186: ...186 Accessories ...

Page 208: ...208 Appendix Safe Torque Off STO ...