20

YORK INTERNATIONAL

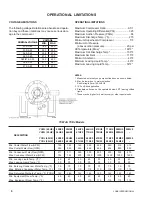

A strainer, preferably 40 mesh,

MUST

be installed in the

cooler and condenser inlet lines, just ahead of the cooler

and condenser.

A small valve or valves should be installed at the highest

point or points in the chilled liquid piping to allow any

trapped air to be purged. Vent and drain connections

should be extended beyond the insulation to make them

accessible. Chiller piping as well as the circulating pump

may be insulated as required to prevent condensation

from forming.

CHILLED LIQUID PIPING

The piping to and from the cooler must be designed to

suit the individual installation. It is important that the

following considerations be observed:

1. The chilled liquid piping system should be laid out

so that the circulating pump discharge is into the

cooler. The suction for this pump should be taken

from the piping system return line and not the cooler.

2. It is recommended that all chilled liquid piping be

thoroughly flushed to free it from foreign material be-

fore the system is placed into operation. Use care

not to flush any foreign material into or through the

cooler.

3. As an aid to servicing, thermometers and pressure

gauges should be installed in the inlet and outlet

water lines. One connection point (plugged) is pro-

vided in each cooler nozzle. Thermometers and

gauges are not furnished with the unit and are to be

furnished by other suppliers.

4. A chilled water flow switch, (either by YORK or oth-

ers)

MUST

be installed in the leaving water piping of

the cooler. There should be a straight horizontal run

of at least 5 diameters on each side of the switch.

Adjust the flow switch paddle to the size of pipe in

which it is to be installed. (See manufacturers in-

structions furnished with switch). The switch is to

be wired to terminals in the control panel as shown

in the WlRING DIAGRAM.

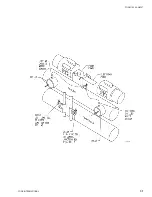

CONDENSER WATER PIPING

Water cooled condensers may be piping for well water

or for use in conjunction with a water cooling tower.

1. WELL WATER If well water with a temperature be-

low 55°F is used to cool the condenser, some means

must be provided to maintain adequate condenser

pressure for proper operation of the expansion valve.

One way to control condenser pressure is to use an

automatic water regulating valve to maintain a mini-

mum leaving water temperature of 65°F .

The regulator should be installed in the entering water

line; however, the outlet piping leaving the condenser

should contain a vertical rise approximately 3" higher

than the top of the condenser before an elbow is in-

stalled to continue the piping to an open drain. The

reason for the vertical riser is to create a trap which

will prevent water from draining out of the condenser

at each shut down. This aids in preventing unneces-

sary and premature fouling of the condenser due to

drying of the tubes (with subsequent rapid build up of

foreign material) during shutdown periods.

It should be determined that the maximum water pres-

sure at the condenser does not exceed the maximum

design working pressure of the condenser (150 PSIG).

In order to insure quiet and satisfactory operation of

the water regulating valve, the manufacturer may limit

the working pressure to which the valve can be sub-

jected.

Where excessive water pressures are encountered, a

pressure reducing valve should be installed ahead of

the water regulating valve to permit reduction of the

condenser water pressure in accordance with the re-

quirements of the condenser and/or water regulating

valve.

2. WATER COOLING TOWER PIPING When install-

ing these chillers with a cooling tower, some means

of controlling head pressure must be provided if op-

eration with entering condenser water temperature

below 55°F is required. Water flow through the cool-

ing tower should be constant, while at the same time,

it must be possible to vary the water flow through the

condenser to keep the condensing pressure and tem-

perature constant regardless of load and outside tem-

perature and wet bulb conditions to assure proper

operation of the thermal expansion valve or valves.

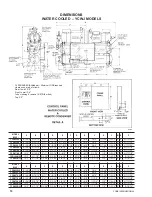

This may be accomplished by installing a 3-way wa-

ter regulating valve as shown in Fig. 6. The valve should

be set to maintain 65°F minimum leaving condenser

water temperature.

The use of a three way water regulating valve with

bypass is highly recommended since it maintains con-

stant condensing pressure regardless of outside tem-

perature conditions and insures proper operation of

the cooler expansion valve.

It is important to follow the instructions of the water

regulating valve manufacturer in regard to installation

recommendations and valve adjustment procedures.

Thermometer wells should be located at the condenser

inlet and outlet to aid in performance and service work.

Содержание YCRJ45E00

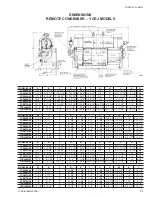

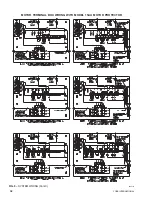

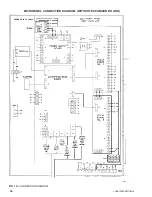

Страница 29: ...FORM 150 24 NM27 YORK INTERNATIONAL 29 CONTROL CIRCUIT With I O Expansion Board LD02106 ...

Страница 30: ...30 YORK INTERNATIONAL FIG 9 SYSTEM WIRING ...

Страница 31: ...FORM 150 24 NM27 YORK INTERNATIONAL 31 LD02678 ...

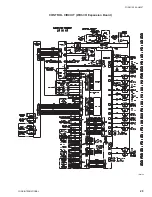

Страница 33: ...FORM 150 24 NM27 YORK INTERNATIONAL 33 LD02357 MOTOR TERMINAL BOX WIRING WITH MODEL 31AA MOTOR PROTECTOR ...

Страница 34: ...34 YORK INTERNATIONAL FIG 10 CONNECTION DIAGRAM LD02358 MICROPANEL CONNECTION DIAGRAM WITHOUT EXPANSION BOARD ...

Страница 35: ...FORM 150 24 NM27 YORK INTERNATIONAL 35 LD02679 ...

Страница 36: ...36 YORK INTERNATIONAL MICROPANEL CONNECTION DIAGRAM With I O Expansion Board LD02107 ...

Страница 37: ...FORM 150 24 NM27 YORK INTERNATIONAL 37 LD02108 ...