100

YORK INTERNATIONAL

TROUBLESHOOTING CHART

PROBLEM

CAUSE

SOLUTION

No display on panel

1. No 115VAC to 2T.

1. Checking wiring and fuses (1 FU and 2

Unit will not operate

FU). Check emergency stop contacts

5

to

1

.

2. No 24VAC to Power Supply Board.

2. Check wiring 2T to Power Supply Board.

3. 2T defective, no 24VAC output.

3. Replace 2T.

4. No +12V output from Power Supply

4. Replace Power Supply Board or isolate

Board.

excessive load on the board.

Contact YORK Service Before Replacing Circuit Boards!

NO RUN PERM

1. No flow.

1. Check chilled liquid flow.

2. Flow switch installed improperly.

2. Check that flow switch is installed

according to manufacturers Instructions.

3. Defective flow switch.

3. Replace flow switch.

4. Remote cycling device open.

4. Check cycling devices connected to

terminals 13 & 14 of the TB3 Terminal

Block.

5. System switch in the OFF position.

5. Place switches to the ON position.

MOTOR CURRENT CONTACTOR DOES NOT ENERGIZE

FAULT

1. External high pressure switch tripped. 1. Check external high pressure switch,

cooling tower operation, and discharge

Motor Contactor may

pressure stored in memory.

or may not Energize

2. External motor protector tripped.

2. Check for defective External motor

protector, wiring and motor problems.

Assure that motor protector is not tripped

due to external high pressure switch.

3. Defective relay output board.

3. Replace relay output board.

CONTACTOR ENERGIZES

1. Improper system high voltage.

1. Check system high voltage supply.

2. Defective contactor contacts and

2. Check contacts and contactor.

contactor.

3. Faulty high voltage wiring.

3. Check wiring.

4. High motor current stored in memory.

4. Loose calibration resistors in J9 (SYS 1)

or J10 (SYS 2) of power supply board.

5. Defective current transformer (CT).

5. CT resistance 42-44

Ω

.

Contact YORK Service Before Replacing Circuit Boards or C.T.s!

LOW OIL PRESS

1. Low oil charge.

1. Oil level should be visible in sight glass

FAULT

at all times. Add YORK C oil if

necessary.

2. Too much refrigerant-in oil,

2. Check crankcase oil heater operation.

particularly on start-up.

(350 Watt heater should be ON when

unit is OFF. Measure heater current.

(Should be min. 2 amps.)

3. Liquid Line Solenoid Valve (LLSV)

3. Check wiring and LLSV.

not operating.

4. Suction Press. Transducer or wiring

4. Compare display to a gauge (SYS OFF).

defective.

Replace defective component.

5. Oil Press. Transducer or wiring -

5. Compare suction and oil gauges to

defective.

display. Replace defective component.

Содержание YCRJ45E00

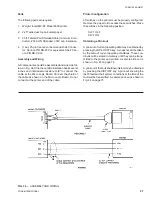

Страница 29: ...FORM 150 24 NM27 YORK INTERNATIONAL 29 CONTROL CIRCUIT With I O Expansion Board LD02106 ...

Страница 30: ...30 YORK INTERNATIONAL FIG 9 SYSTEM WIRING ...

Страница 31: ...FORM 150 24 NM27 YORK INTERNATIONAL 31 LD02678 ...

Страница 33: ...FORM 150 24 NM27 YORK INTERNATIONAL 33 LD02357 MOTOR TERMINAL BOX WIRING WITH MODEL 31AA MOTOR PROTECTOR ...

Страница 34: ...34 YORK INTERNATIONAL FIG 10 CONNECTION DIAGRAM LD02358 MICROPANEL CONNECTION DIAGRAM WITHOUT EXPANSION BOARD ...

Страница 35: ...FORM 150 24 NM27 YORK INTERNATIONAL 35 LD02679 ...

Страница 36: ...36 YORK INTERNATIONAL MICROPANEL CONNECTION DIAGRAM With I O Expansion Board LD02107 ...

Страница 37: ...FORM 150 24 NM27 YORK INTERNATIONAL 37 LD02108 ...