FORM 150.40-NM20

39

YORK INTERNATIONAL

tive switch must be in the “ON” position.

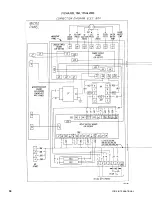

4. “DATA DISPLAY CODES”

Refer to this list when selecting the desired system

parameter to be displayed. A list of the codes and

their respective number is shown in Fig. 14.

5. “UNIT START-UP SEQUENCE”

This is a simplified start-up procedure for switch setup

of the panel and system.

6. “SYSTEM MONITORING OR DIAGNOSIS”

This list informs the operator of the meaning of the

alphabetic codes which may appear on the display.

Anti-recycle status, external device status, and fault

information is displayed using this alphabetical code.

(See Fig.13 and 14.)

7. “FAULT CODES”

Any time an “F” appears on the display, one or both

compressors will be shut down on a safety control.

At this time, the operator should turn the “SELECT

DATA DISPLAY” rotary switches to the number “18”.

When this is done, a Fault Code will appear which

can be compared to the “FAULT Code” list to deter-

mine the reason for system failure. A list of the codes

and their respective number is shown in Fig. 14.

An “F” Code overrides any other letter code display

which may appear. See the “SHUTDOWN SAFETY

CONTROLS” and “MANUAL RESET SAFETY CON-

TROLS” Section for a more detailed explaination of

the codes.

8. “WATER COOLING RANGE CODE”

Refer to this list when setting up the “WATER COOL-

ING RANGE” rotary switch. Since the switch does

not read directly, decoding is necessary.

9. “SYS 1 LEAD/LAG” Select

This switch allows the operator to select SYS 1 as

the lead or lag compressor. Note: See Micro Logic

Board Jumper/Switch Section for automatic lead/lag

switching by the Micro Logic Board.

10. “SELECT DATA DISPLAY” Switches

These switches can be used to display 18 Test Points

for troubleshooting and data recording. This is done

via the 2 Rotary Switches marked “Select Data Dis-

play”. To look at a specific function, select the num-

ber of the function from the “Data Display Codes”

listing on the panel.

Proceed by dialing the number up on the “Select Data

Display” Rotary Switches. In the event of a failure,

the failure can be displayed by selecting #18 of the

“Select Data Display”. The mode of failure will then

be indicated by a number from 0-11. This number

can be translated by comparing the number to the

“Fault Code” listing on the right side of the panel.

(YCHA120, 150, 175, & 200)

• System 2 % Full Load Motor Current

• System 2 Suction Pressure

• System 2 Oil Pressure, PSID

• System 2 Discharge Pressure

• Suction Pressure Cutout Setting, PSIG

• Water Cooling Range Temperature

(Also see Fig. 14 for a complete list)

The system “Return Chilled Water Temp” is entered by

two rotary switches and the “Water Cooling Range” by

a single rotary switch.

System 1 and 2 can be activated by 2 toggle switches.

These switches normally remain “ON” after startup. A

toggle switch is available to select compressor #1 as

the lead or lag system.

Remote cycling, unloading, and Return Chilled Water

Temp Setpoint Reset can be accomplished as noted

on Page 42. Loading and unloading decision making is

done by software on the Micro Logic Board. These de-

cisions are made according to temperature deviations

from the selected setpoint and the selected cooling

range resulting in more precise control of water tem-

perature.

CONTROL PANEL

1. “CHILLED WATER TEMP SELECT”*

Control is achieved by Return Chilled Water Setpoint

(adjustable from 0°F to 70°F in one degree incre-

ments). Setpoint is entered via two rotary switches

on the control panel marked “Chilled Water Temp.

Select °F”.

*If needed,the unit can be configured to control Leav-

ing Chilled Water Temp. This can be accomplished

by a jumper/switch on the Micro Board. See Fig. 20

& 21.

J10 OUT / SW. 3 OFF RWT Control

J10 IN / SW. 3 ON LWT Control

NOTE: It is recommended that RWT control be used

unless LWT control is absolutely necessary.

Control via LWT is best obtained using optional

additional steps of loading. Contact YORK Sales

for this option.

2. “WATER COOLING RANGE” Select Switch

Temperature control range is variable via a single

rotary switch labeled “Water Cooling Range”. There

will be a choice of eight settings (0-7). Available

ranges are 6.0°F, 7.0°F, 8.0°F, 9.0°F, 10.0°F, 11.0°F,

12.0°F, and 14.0°F, corresponding to setting 0-7 re-

spectively.

3. SYS 1 and SYS 2 “ON/OFF” Switches

These switches allow the operator to manually turn

off either system. To operate a system, the respec-

Содержание YCAQ10

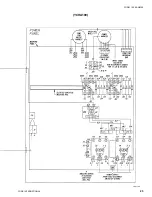

Страница 20: ...YORK INTERNATIONAL 20 LD01779 YCHA100 FIG 9 WIRING DIAGRAM YCHA100...

Страница 21: ...FORM 150 40 NM20 21 YORK INTERNATIONAL YCHA100 LD01779 D...

Страница 22: ...YORK INTERNATIONAL 22 LD01780 L YCHA100 FIG 9 Continued...

Страница 23: ...FORM 150 40 NM20 23 YORK INTERNATIONAL LD01780 R YCHA100...

Страница 24: ...YORK INTERNATIONAL 24 YCHA100 LD01781 FIG 9 Continued...

Страница 25: ...FORM 150 40 NM20 25 YORK INTERNATIONAL LD01782 YCHA100...

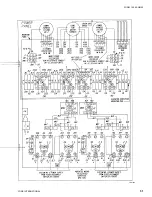

Страница 46: ...YORK INTERNATIONAL 46 LD01787...

Страница 47: ...FORM 150 40 NM20 47 YORK INTERNATIONAL LD01788...

Страница 48: ...YORK INTERNATIONAL 48 LD01789...

Страница 49: ...FORM 150 40 NM20 49 YORK INTERNATIONAL LD01790...

Страница 50: ...YORK INTERNATIONAL 50 LD01791...

Страница 51: ...FORM 150 40 NM20 51 YORK INTERNATIONAL LD01792...

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......