FORM 150.40-NM20

17

YORK INTERNATIONAL

SYSTEM SAFETIES

SHUTDOWN SAFETY CONTROLS

A. These software controls in the Micro Board automati-

cally reset and allow restart of the system without

operator intervention (auto-restart) when the condi-

tion causing the shutdown clears. After the condition

causing the shutdown clears, the unit will restart in a

minimum of 2 minutes or a maximum of 10 minutes,

depending upon the remaining time on the

anti-recycle timer. Restart will occur only if cooling

demand is present. An “F” code will be displayed for

LAT* and HAT* shutdowns. Otherwise, no code will

be displayed other than one indicating the anti-recycle

timer(s) is in effect.

1. Power Failure: After power has been restored, the

unit will automatically restart after a 2 minute time

delay. System acts as it does any time power is ap-

plied. Restart is dependent on cooling demand after

the 2 minute start-up timer has completed its cycle.

2. Flow Switch/Remote Cycling Device: The Micro

Board monitors the closure of the Flow Switch Con-

tacts. Upon opening of the contacts, the unit will shut

down and will remain off until the contacts close.

Remote devices are wired in series with the Flow

Switch and can be used to start and stop the unit.

Anytime the contacts open, an “A” Code will appear

on the display indicating a Flow Switch problem or

an EMS/BAS/Time Clock stop.

3. Low Pressure Cutout: Compressor suction pres-

sure cutout is a factory adjustable setpoint (R26) on

the Analog Board. It will be factory set at 44 PSIG. If

Glycol or Brine is utilized, then the cutout can be var-

ied according to mixture. Suction pressure must be

80% cutout after 30 sec. of running and must remain

above cutout after 4 minutes of operation. The sys-

tem will restart after an LP shutdown provided the

anti-recycle timer has timed out and a minimum 2

minute delay before restart has passed.

NOTE: The system will be locked out on a Fault if cycled

on LP on 3 successive starts. See LEP (Low

Evaporator Pressure Cutout) in the MANUAL

RESET SAFETY CONTROLS section.

4. Low Ambient Temperature Cutout (LAT*): Unit is

locked out when the ambient temperature is below

0° to 50°F (Adjustable on Analog Board resistor R24).

This is factory set at 35°F. Upon a rise in tempera-

ture above setpoint, the unit will restart provided the

anti-recycle timer has timed out and a minimum

2-minute delay has passed. An “F 10” code will be

displayed while the temperature is low and the sys-

tem will be shut down. The “F” will disappear when

temp. rises above cut-out.

5. High Ambient Temperature Cutout (HAT*): Unit locks

out when the ambient temperature is above 130°F.

Upon a decrease in temperature below 130°F, the unit

will restart providing the anti-recycle timer has timed

out and a minimum 2-minute delay has passed. An

“F9” code will be displayed while the temperature is

high and the system will be shut down. The “F” will

disappear when temp. drops below cut-out.

MANUAL RESET SAFETY CONTROLS

A. The system will shut down instantly when a Manual

Reset Fault is sensed, but it will allow automatic re-

start until it sees a total of any 3 Faults in a 90-minute

period.**A 90-minute counter is started as soon as

the first Fault occurs. If 2 more faults do not occur in

the next 90 minutes, the counter is reset to “0”.

After a fault, restart cannot be expected until the anti-re-

cycle timers time out. No display (“F” Code) will be indi-

cated during the first two faults except for a letter code

telling the operator the anti-recycle timer is in effect.

After 3 faults, an “F” code will be displayed and the

system will not restart. The fault can be cleared and the

compressor restarted by placing the System Off/On

Switch to the OFF position. However another fault will

shut down the system and an “F” code will be displayed.

The system will continue to shut down after restart on

every Fault with an “F” Code until the system runs with-

out faulting for 90 minutes or until power is cycled. Re-

cycling power will reset the counter to “0”.

1. HP: Unit shuts down when the discharge pressure

exceeds the pressure cutout setpoint of 395 PSI set

in software. An “F4” will appear for this safety. See

also Note 6) FS (Fault Stop) for external HP safety.

2. Power Fault: Analog signals are provided to the Micro-

Board by the Motor Current Board (MCB) which gets

info from 3 current transformers (C.T.’s). A signal of

4VDC = 100% FLA Current. The system shuts down

if the signal is <1.2VDC (<30% FLA) or 4.6 VDC

(>115% FLA) when Run Time > 4 sec. This protection

assures that both contactors are energized, all C.T.’s

are connected and operating, and that the motor is

not drawing excessive current. An F1 will be displayed

for this safety. NOTE: See also Note 6) FS (Fault Stop).

3. Oil Pressure Cutout: An analog signal is provided

which is the Differential Oil Pressure (PSID). This

PSID provided to the Micro Board = Oil Pressure

PSIG - Suction Pressure PSIG. The system shuts

down if < 10 PSID at run time 4 - 30 seconds; if <25

PSID at run time 30 seconds - 4 minutes; or if <20

PSID at run time > 4 minutes. An “F2” will be dis-

played for this cut-out.

(YCAH100)

* These controls are not furnished as part of the standard unit. A

10K ohm resistor is used in place of them.

** This does not apply to item #4 (LWT Freeze Safety). A fault on

the LWT Freeze Safety will cause the system to shut down and

lock out on a single fault.

Содержание YCAQ10

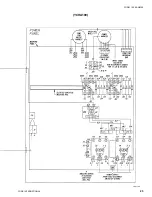

Страница 20: ...YORK INTERNATIONAL 20 LD01779 YCHA100 FIG 9 WIRING DIAGRAM YCHA100...

Страница 21: ...FORM 150 40 NM20 21 YORK INTERNATIONAL YCHA100 LD01779 D...

Страница 22: ...YORK INTERNATIONAL 22 LD01780 L YCHA100 FIG 9 Continued...

Страница 23: ...FORM 150 40 NM20 23 YORK INTERNATIONAL LD01780 R YCHA100...

Страница 24: ...YORK INTERNATIONAL 24 YCHA100 LD01781 FIG 9 Continued...

Страница 25: ...FORM 150 40 NM20 25 YORK INTERNATIONAL LD01782 YCHA100...

Страница 46: ...YORK INTERNATIONAL 46 LD01787...

Страница 47: ...FORM 150 40 NM20 47 YORK INTERNATIONAL LD01788...

Страница 48: ...YORK INTERNATIONAL 48 LD01789...

Страница 49: ...FORM 150 40 NM20 49 YORK INTERNATIONAL LD01790...

Страница 50: ...YORK INTERNATIONAL 50 LD01791...

Страница 51: ...FORM 150 40 NM20 51 YORK INTERNATIONAL LD01792...

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......