YORK INTERNATIONAL

26

SYSTEM START-UP AND OPERATION

Checking the System 24 Hours Prior to Initial Start-

Up (No Power)

1. UNIT CHECKS

A. Inspect the unit for shipping or installation damage.

B. Assure that all piping has been completed and

flushed.

C. Check that the unit is properly charged and that

there are no piping leaks.

D. Suction and discharge stop valves and the refrig-

erant liquid stop valves are open (ccw).

CAUTION

Compressor lubrication circuit must be primed with

YORK “C” oil prior to start-up. Priming should be

done through the Schrader fitting at the compres-

sor oil pump. Stroke oil pump 10 times to prime the

lubrication circuit.

E. “Full” oil quantity is shown by an oil level showing

in the upper sight glass. “Low” oil quantity is shown

by an oil level showing in the lower sight glass. If it

is necessary to add oil, connect a YORK oil pump

to the oil charging valve, but do not tighten the

flare nut on the delivery tubing. With the bottom

(suction end) of the pump submerged in oil to avoid

the entrance of air, operate the pump until oil drips

from the flare nut joint, allowing the air to be ex-

pelled, and tighten the flare nut. Open the com-

pressor oil charging valve and pump in oil until oil

reaches the proper level as described above.

Close the compressor oil charging valve.

F. Assure water pumps are on. Check and adjust

water pump flow rate and pressure drop across

cooler. Verify flow switch operation.

G. Check panel to see that it is free of foreign mate-

rial (wires, metal chips, etc.).

H. Visually inspect wiring (power & control). Must

meet NEC and all local codes.*, **

I. Check for proper size fuses in main and control

power circuits.

J. Verify that field wiring matches the 3-phase power

requirements of the compressor. See nameplate.**

K. Assure 115VAC Control Power to TB1 has 30A

minimum capacity.*

L. Be certain all control bulbs are inserted completely

in their respective wells and are coated with heat

conductive compound.

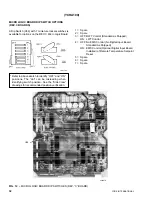

2. PANEL CHECKS (Power On, System Switch “Off”)

A. Apply 3 phase power and verify its value.**

B. Apply 115VAC and verify its value on the terminal

block in the lower right of the Logic Panel. Make

the measurement between terminals 41 and 2.

Should be 10%.*

C. Assure crankcase heaters are on. Allow crank-

case heaters to remain on a minimum of 24 hours

before startup. This is important to assure no re-

frigerant is in the oil at start-up!

D.

Checking The Electronics

A few simple checks will assure that the panel

electronics are working and that the system will

run when you come back in 24 hrs. for start-up.

Checking the Microprocessor Board and its Par-

allel Interface

Display the Return Water Temp. Setpoint and

verify that it matches the Return Water Temp.

Setpoint Switches.

Checking the Analog Input Board and the Micro-

processor Board’s A/D Converter

Display the Low Suction Pressure Cutout, Low Wa-

ter Temp. Cutout, and Low Ambient Cutout. These

displays should match the printout placed inside

the unit. The printout will provide the unit specs. on

the cutouts as ordered by the customer. Deviation

from these could be due to a defective board or

tampering with the Analog Input Board pots.

Checking the R.P. Relay

Remove the wire on terminal 3 & 4 of the terminal

block in the lower right corner Logic Panel. Note:

Water flow should be present and any remote cy-

cling devices jumpered. By removing the wire, we

simulate an open flow switch or cycling device. Con-

sequently an “A” code should appear on the display.

Checking the Power Supply Board

If the other boards check out alright, there is al-

most a100% chance that the Power Supply Board

is functioning properly. If any board malfunctions,

check its supply voltages. UNREG voltages nor-

mally measure 40% high + 10%. REG voltages

should be +.1V.

E. By performing the previous checks, we will assure

most of the system is functioning properly. Ther-

mistors and transducers can be checked at this point.

The display can be checked against a gauge if de-

sired. To assure proper return and leaving water

temp. displays, flow must be present. We won’t be

worrying about checking out the Relay Output Board.

This board is easy to diagnose and can easily be

field repaired with factory assistance if the need

arises.

INITIAL START-UP

After the operator has read the proceeding pages, has

become familiar with the control panel and its functions,

and has performed the proceeding unit checks and

panel checks, the unit can be put into operation. Pro-

ceed by setting the switches as follows:

(YCHA100)

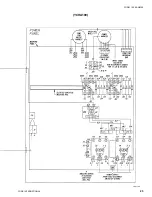

*See Fig. 7.

**See Fig. 8.

Содержание YCAQ10

Страница 20: ...YORK INTERNATIONAL 20 LD01779 YCHA100 FIG 9 WIRING DIAGRAM YCHA100...

Страница 21: ...FORM 150 40 NM20 21 YORK INTERNATIONAL YCHA100 LD01779 D...

Страница 22: ...YORK INTERNATIONAL 22 LD01780 L YCHA100 FIG 9 Continued...

Страница 23: ...FORM 150 40 NM20 23 YORK INTERNATIONAL LD01780 R YCHA100...

Страница 24: ...YORK INTERNATIONAL 24 YCHA100 LD01781 FIG 9 Continued...

Страница 25: ...FORM 150 40 NM20 25 YORK INTERNATIONAL LD01782 YCHA100...

Страница 46: ...YORK INTERNATIONAL 46 LD01787...

Страница 47: ...FORM 150 40 NM20 47 YORK INTERNATIONAL LD01788...

Страница 48: ...YORK INTERNATIONAL 48 LD01789...

Страница 49: ...FORM 150 40 NM20 49 YORK INTERNATIONAL LD01790...

Страница 50: ...YORK INTERNATIONAL 50 LD01791...

Страница 51: ...FORM 150 40 NM20 51 YORK INTERNATIONAL LD01792...

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......