FORM 150.40-NM20

11

YORK INTERNATIONAL

COMPRESSOR MOUNTING

The compressor(s) are mounted on four (4) isolator pads

(one under each compressor foot). (See Fig. 3.) The

mounting bolts are not to be loosened or adjusted at

installation.

4. All chilled liquid piping should be thoroughly

flushed to free it from foreign material before the

system is placed into operation. Use care not to

flush any foreign material into or through the

cooler.

5. As an aid to servicing, thermometers and pressure

gauges are recommended for installation in the inlet

and outlet water lines. One connection point (plugged)

is provided in each cooler nozzle. Thermometers and

gauges are not furnished with the unit and are to be

furnished by other suppliers.

6. The chilled liquid lines that are exposed to outdoor

ambients should be wrapped with a supplemental

heater cable and insulated to protect against

freeze-up during low ambient periods, and to pre-

vent fomlation of condensation on lines in warm

humid climates.

7. A chilled water flow switch, (either by YORK or oth-

ers) must be installed in the leaving water piping of

the cooler. There should be a straight horizontal run

of at least 5 diameters on each side of the switch.

Adjust the flow switch paddle to the size of pipe in

which it is to be installed. (See: manufacturer’s in-

structions furnished with switch.) The switch is to

be wired to terminals in the control panel as shown

in the WIRING DIAGRAM.

WARNING: Flow switch must not be used to stop

and start chiller.

ELECTRICAL WIRING

The YORK Series YCHA Packaged Liquid Chillers are

shipped with all contained controls wired for operation.

Field Wiring – Power wiring must be provided through

a fused disconnect switch. Minimum circuit ampacity

and maximum dual element fuse size are given on page

6. A 115-1-60/ 50, 30 amp source must be supplied for

the control panel through a fused disconnect when a

control panel transformer (optional) is not provided.

Refer to Wiring Diagrams.

Affiliated apparatus, such as a chilled water flow switch,

auxiliary contacts from the chilled water pump starter,

alarms, etc. should be interlocked into the control panel

circuit. These field modifications may be made as shown

on the WIRING DIAGRAMS.

MULTIPLE UNITS

For increased compressor protection and to reduce

power inrush at start-up on multiple chiller installa-

tions, provisions must be made to prevent simulta-

neous start-up of two or more units. Also, some

method must be employed to automatically cycle on

or off one or more of the units to permit more effi-

cient operation at part load conditions. A sequencing

kit may be acquired through your local YORK repre-

sentative.

CHILLED LIQUID PIPING

General – When the unit has been located in its final

position, the unit liquid piping may be connected. Nor-

mal installation precautions should be observed in or-

der to receive maximum operating efficiencies. Piping

should be kept as free as possible of all foreign matter.

All liquid cooler piping must comply in all respects with

local plumbing codes and ordinances.

Since elbows tees and valves decrease pump capacity,

all piping should be kept as simple as possible.

Hand stop valves should be installed in all lines to facili-

tate servicing.

Piping to the inlet and outlet connections of the chiller may

include high-pressure rubber hose or piping loops to in-

sure against transmission of vibration. This is optional and

the necessary components must be obtained in the field.

Drain connections should be provided at all low points

to permit complete drainage of liquid cooler and piping

system.

A small valve or valves should be installed at the high-

est point or points in the chilled liquid piping to allow

any trapped air to be purged. Vent and drain connec-

tions should be extended beyond the insulation to make

them accessible.

The piping to and from the cooler must be designed to

suit the individual installation. It is important that the

following considerations be observed:

1. The chilled liquid piping system should be laid out

so that the circulating pump discharges directly into

the cooler. The suction for this pump should be taken

from the piping system return line and not the cooler.

2. The inlet and outlet cooler liquid connection sizes

are given on pages 4 and 5.

3. It is recommended that a strainer, preferably 40

mesh, be installed in the cooler inlet line just ahead

of the cooler.

00006TG

FIG. 3 – COMPRESSOR MOUNTING PAD

Содержание YCAQ10

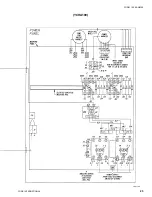

Страница 20: ...YORK INTERNATIONAL 20 LD01779 YCHA100 FIG 9 WIRING DIAGRAM YCHA100...

Страница 21: ...FORM 150 40 NM20 21 YORK INTERNATIONAL YCHA100 LD01779 D...

Страница 22: ...YORK INTERNATIONAL 22 LD01780 L YCHA100 FIG 9 Continued...

Страница 23: ...FORM 150 40 NM20 23 YORK INTERNATIONAL LD01780 R YCHA100...

Страница 24: ...YORK INTERNATIONAL 24 YCHA100 LD01781 FIG 9 Continued...

Страница 25: ...FORM 150 40 NM20 25 YORK INTERNATIONAL LD01782 YCHA100...

Страница 46: ...YORK INTERNATIONAL 46 LD01787...

Страница 47: ...FORM 150 40 NM20 47 YORK INTERNATIONAL LD01788...

Страница 48: ...YORK INTERNATIONAL 48 LD01789...

Страница 49: ...FORM 150 40 NM20 49 YORK INTERNATIONAL LD01790...

Страница 50: ...YORK INTERNATIONAL 50 LD01791...

Страница 51: ...FORM 150 40 NM20 51 YORK INTERNATIONAL LD01792...

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......

Страница 96: ......

Страница 97: ......

Страница 98: ......

Страница 99: ......