40

YORK INTERNATIONAL

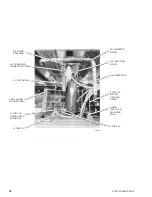

valve open to load the compressor. Electrical pulses open

a solenoid valve, allowing oil pressure to move the piston

which operates the slide valve. The pulses originate at the

micro and are a function of the required load on the chiller

in response to leaving water temperature.

The micro must repetitively pulse the slide valve to

maintain a constant load. This is required because

discharge pressure is always present on the other end of

the slide valve, trying to force it closed.

To unload the compressor, a second solenoid is opened,

which vents oil pressure away from the piston. By

releasing the pressure on the piston, the discharge

pressure is able to push the valve toward the closed or

unload position.

It will be noted that slide valve movement is greater at high

discharge pressures. This is due to higher oil pressure

which is directly proportional to discharge pressure.

Higher oil pressures exert more pressure on the slide

valve causing greater movement as the slide valve is

pulsed with oil. This condition is normal. Also normal and

a result of compressor design is non-linear movement at

various points in the slide valve travel as the slide valve

is pulsed. Closely monitoring the movement will show that

the slide valve will move easier at the ends and in the

center of its travel range.

When the compressor is shut down, a check valve

releases oil from the piston. Since no discharge pressure

is available to push the valve closed, the slide valve will

maintain the position it was in when the compressor

stopped. To assure the compressor starts unloaded, the

micro sends an unload signal to the slide valve on start-

up. In some cases, oil pressure may not be high enough

at start-up to move the slide valve. This means the

compressor could start-up partially loaded. This will

seldom occur and will not hurt the motor due to the extra

torque built into the design.

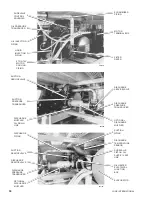

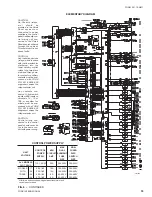

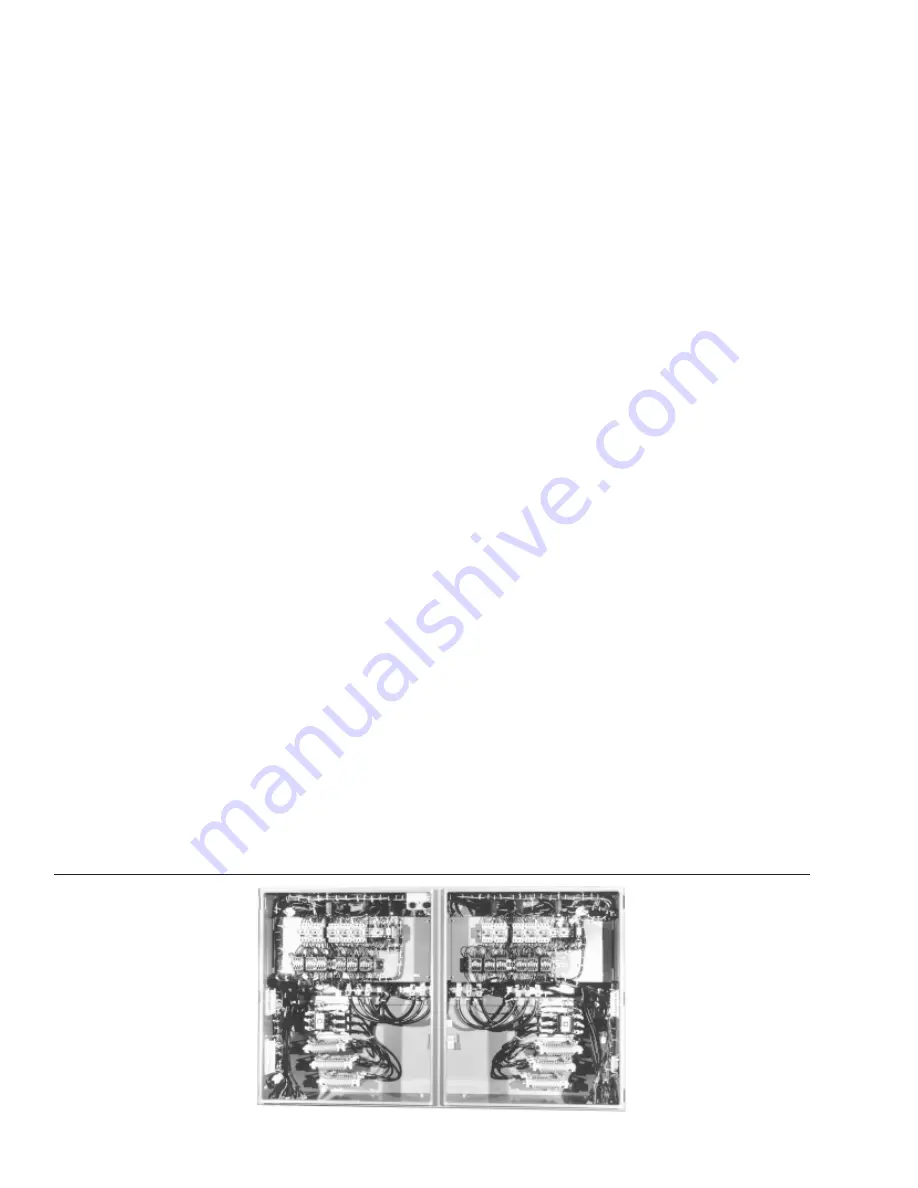

STARTER

Two types of compressor motor starting are available:

Across-the-line and optional Wye-Delta Closed Transition

Starter. The Across-the-line starters will utilize one

contactor per compressor.

The optional Wye-Delta starter utilizes 4 contactors, a

time delay relay, and wire wound power resistors for each

compressor. See Fig. 5.

The Wye-Delta start allows inrush current to be limited to

approximately 33% LRA for the first 15 seconds with

current increasing to normal running current when the

Delta connection is completed.

When the micro initiates a start signal to run a

compressor, the 1CR (SYS 1) or 2CR (SYS 2) relay is

energized. At the same time, the 1TR (SYS 1) or 2TR

(SYS 2) “15 second” time delay relay is energized and

begins timing. The transition of the 1CR (SYS 1) or 2CR

(SYS 2) contactor also energizes 1S (SYS 1) or 2S (SYS

2) normally open auxiliary interlock contacts after

approximately 16ms which in turn energizes the 1M (SYS

1) or 3M (SYS 2) motor contactor after approximately

another 16ms. This completes the “WYE” connection of

the motor start. At the same time, the normally closed 1S

or 2S auxiliary interlock open, preventing 2M (SYS 1) or

4M (SYS 2) from energizing.

The “WYE” connection of the motor start is enabled for

approximately 15 seconds. When the 1TR or 2TR timer

times out after 15 seconds, the interlock contacts

energize 1A (SYS 1) or 2A (SYS 2) “TRANSITION”

contactor which puts the resistance networks across

each winding of the “WYE” connection. At the same time,

the normally closed 1A or 2A auxiliary interlock contacts

de-energize 1S or 2S after approximately 16ms. The

normally closed auxiliary interlock contacts on 1S or 2S

will close energizing 2M or 4M after approximately 16ms.

With the 1M or 3M contactors already held in by the 1M

or 3M auxiliary contacts and 2M or 4M energized, the

normally closed auxiliary interlock contact on 2M or 4M

contactor holding in the 1A or 2A “TRANSITION” contactor

opens removing the resistor network and completing the

“DELTA” connection of the “WYE-DELTA” start.

FIG. 5 – POWER PANEL (WITH WYE-DELTA STARTING)

27963A

Содержание Millennium YCAS 216X

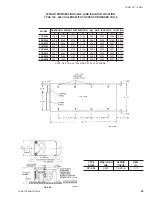

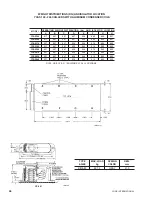

Страница 11: ...FORM 201 10 NM1 11 YORK INTERNATIONAL YCAS 140 246 DIMENSIONS English LD01444 LD01446...

Страница 13: ...FORM 201 10 NM1 13 YORK INTERNATIONAL YCAS 140 246 DIMENSIONS SI LD01440 LD01442...

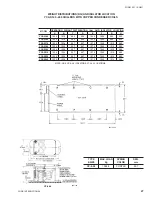

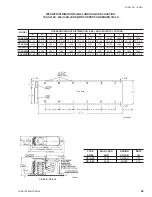

Страница 15: ...FORM 201 10 NM1 15 YORK INTERNATIONAL YCAS 216X 266X DIMENSIONS English LD01454 LD01454...

Страница 17: ...FORM 201 10 NM1 17 YORK INTERNATIONAL YCAS 216X 266X DIMENSIONS SI LD01450 LD01448...

Страница 33: ...FORM 201 10 NM1 33 YORK INTERNATIONAL 28514A FILTER DRYER LIQUID STOP VALVE...

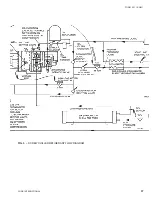

Страница 37: ...FORM 201 10 NM1 37 YORK INTERNATIONAL LD01285 FIG 3 SCREW CHILLER REFIGERANT FLOW DIAGRAM...

Страница 54: ...54 YORK INTERNATIONAL FIG 9 SYSTEM WIRING YCAS 140 246 CONNECTION DIAGRAM SYSTEM WIRING LD01466 D...

Страница 59: ...FORM 201 10 NM1 59 YORK INTERNATIONAL FIG 11 CONTINUED LD01465 D...

Страница 60: ...60 YORK INTERNATIONAL FIG 12 CONNECTION DIAGRAM WYE DELTA YCAS 140 246 CONNECTION DIAGRAM WYE DELTA LD01458 D...

Страница 61: ...FORM 201 10 NM1 61 YORK INTERNATIONAL FIG 12 CONTINUED LD01458 D...

Страница 69: ...FORM 201 10 NM1 69 YORK INTERNATIONAL FIG 16 CONTINUED LD01206 D...

Страница 71: ...FORM 201 10 NM1 71 YORK INTERNATIONAL FIG 17 CONTINUED LD01202 D...