B95W

Maintenance

190 / 306

6

06_Wartung und Pflege_en.fm - V1.0 - 1.8.17

20

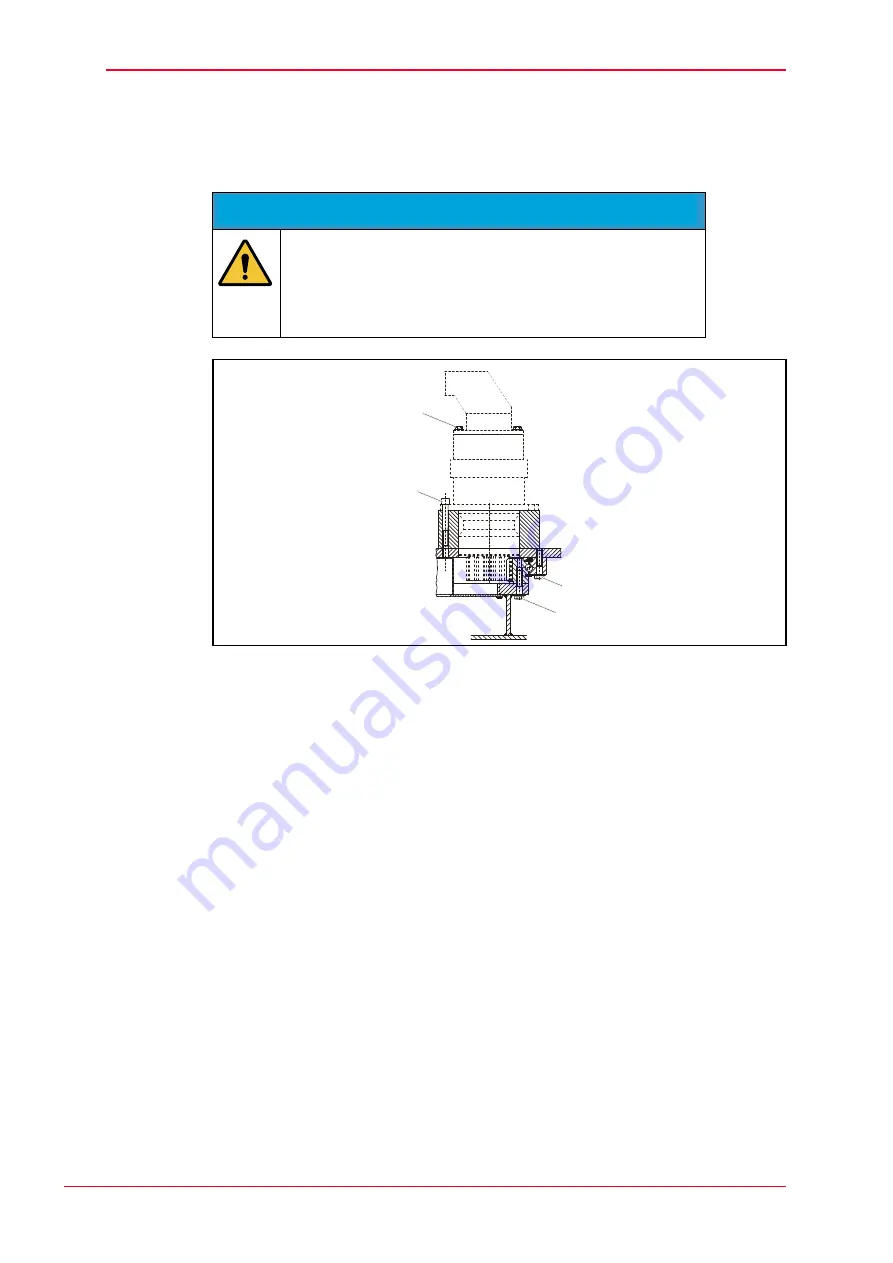

Checking the fastening of slewing joint and swing assembly

Fig. 6-38 Torque values

The following mounting conditions are prerequisites for an optimum bolted

connection on the undercarriage and the uppercarriage:

The contact faces of the screw/bolt heads must be bare metal, i.e., absolutely

free from grease and paint.

The thread and the screw/bolt head, particularly the toothing of the head,

must not be damaged.

Check all accessible screws for the specified tightening torques.

CAUTION

Danger posed by damaged screws

Danger due to damage to the machine.

Z

Replace damaged screws/bolts immediately.

Z

After installing new ones: Check the tightening torque of the

screws/bolts after 100 operating hours.

MA = 72 Nm

MA = 195 Nm

MA = 325 Nm

MA = 325 Nm

Содержание B95W

Страница 2: ......

Страница 8: ...B95W Table of contents 6 306 1 01_Inhaltsverzeichnis_enIVZ fm V1 0 1 8 17 10 ...

Страница 52: ...B95W Description 50 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Страница 58: ...B95W Description 56 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Страница 206: ...B95W Maintenance 204 306 6 06_Wartung und Pflege_en fm V1 0 1 8 17 20 ...

Страница 208: ...B95W Operation 206 306 7 07_Bedienung_en fm V1 0 1 8 17 26 ...

Страница 238: ...B95W Operation 236 306 7 07_Bedienung_en fm V1 0 1 8 17 26 Optional SAE control system Fig 7 14 Lever control 3 5 4 1 2 ...

Страница 272: ...B95W Transport 270 306 8 08_Transport_en fm V1 0 1 8 17 27 ...

Страница 302: ...B95W Troubleshooting 300 306 10 10_Fehlerbeseitigung_en fm V1 0 1 8 17 30 ...

Страница 309: ......

Страница 310: ...http www yanmar eu MOBILE EXCAVATOR ...