Package thickness

Volume mm

3

<350

Volume mm

3

350-2000

Volume mm

3

>2000

< 1.6mm

260°C

260°C

260°C

1.6mm - 2.5mm

260°C

250°C

245°C

> 2.5mm

250°C

245°C

245°C

Table 28: Package classification reflow temperature, PB-free assembly, Note: refer to IPC/-

JEDEC J-STD-020E

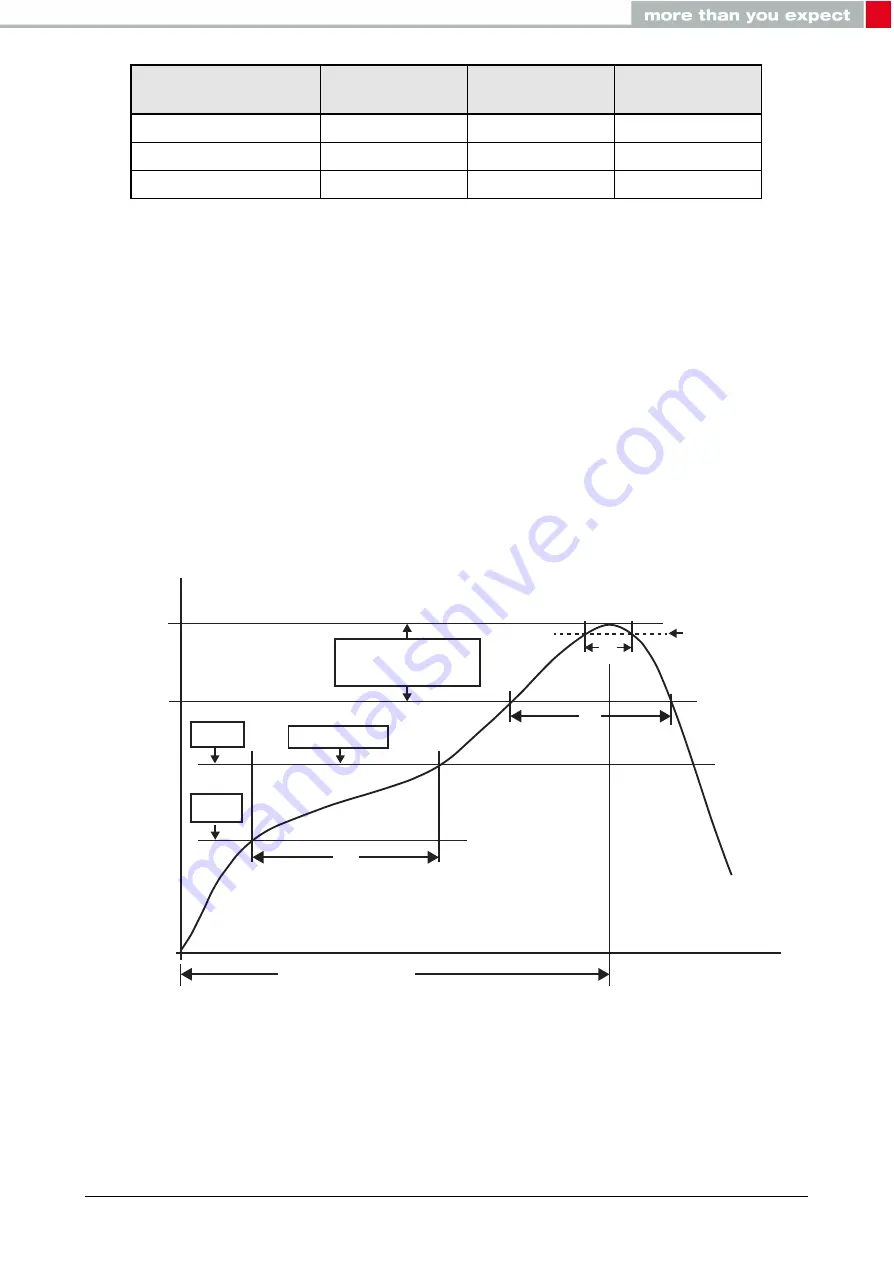

It is recommended to solder this module on the last reflow cycle of the PCB. For solder paste

use a LFM-48W or Indium based SAC 305 alloy (Sn 96.5 / Ag 3.0 / Cu 0.5 / Indium 8.9HF /

Type 3 / 89%) type 3 or higher.

The reflow profile must be adjusted based on the thermal mass of the entire populated PCB,

heat transfer efficiency of the reflow oven and the specific type of solder paste used. Based

on the specific process and PCB layout the optimal soldering profile must be adjusted and

verified. Other soldering methods (e.g. vapor phase) have not been verified and have to be

validated by the customer at their own risk. Rework is not recommended.

Time

Temperature

T

p

t

p

t

L

t

S

T

s max

T

s min

T

C

–5°C

T

L

25

Time 25°C to Peak

Preheat Area

Max. Ramp Up Rate

Max. Ramp Down Rate

Figure 32: Reflow soldering profile

Proteus-III reference manual version 1.3

© August 2020

www.we-online.com/wireless-connectivity

198