Chapter 10

Troubleshooting

32708885 Geset 100

Version: 16.07.13

Page 73 of 77

GB

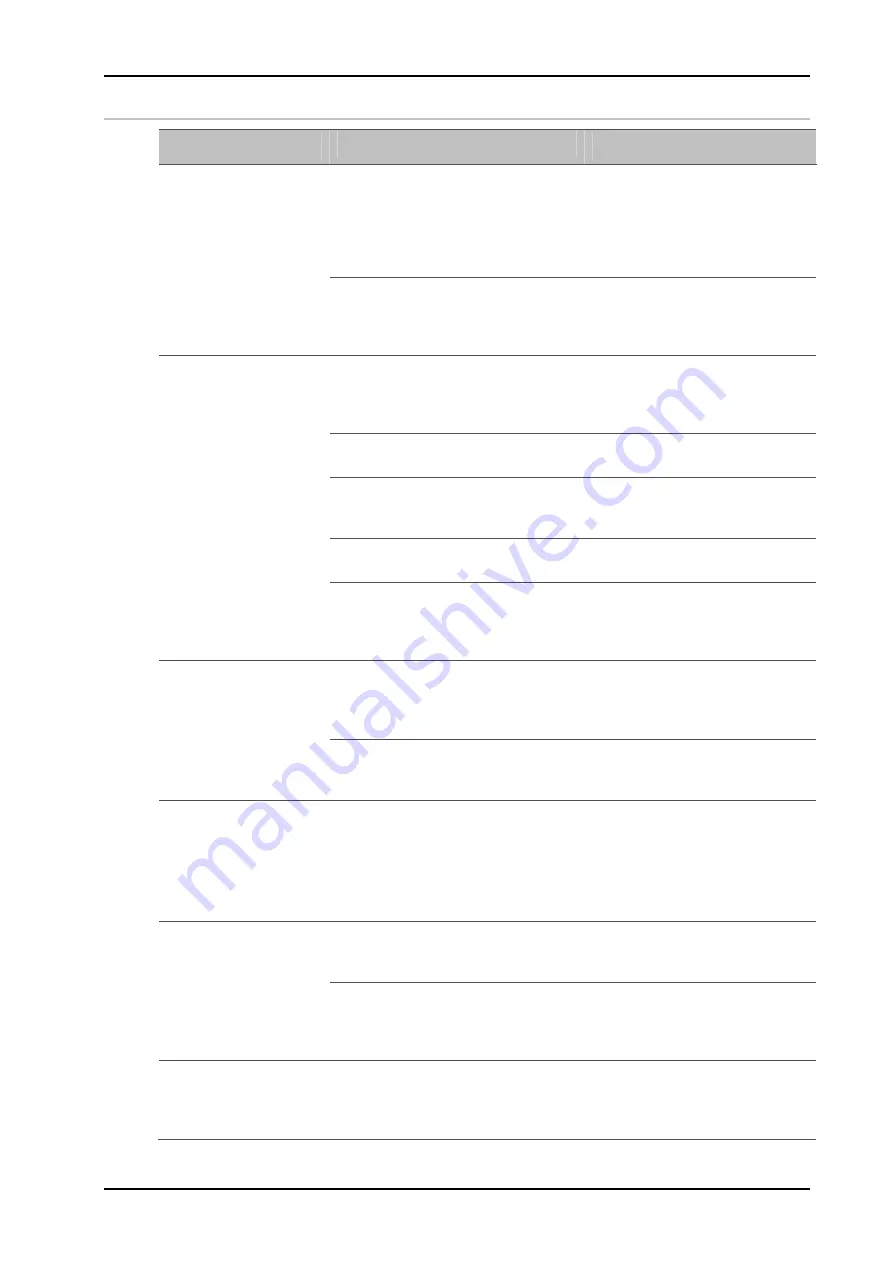

Mechanical error

Problem

Possible cause

Solution

Label liner tears.

Label roll is damaged.

Nicks or label cutter-die damage on

liner.

Dents/damages at the side of the

label roll.

The liner width varies significantly.

Exchange label roll.

Adhesive residues in the area of

the peeler bar.

Remove adhesive residues and

check the label roll for damages

caused by adhesive residues.

Otherwise exchange roll.

Label placement on

the product is consis-

tently poor.

The product is not yet/ not anymore

incorrect labeling position.

Check sensors of the conveyor

used to determine the product’s

stop position.

Product sensor (or its reflector) are

loose or vibrate.

Check sensors and remount, if

required.

Changing conveyor speed (e.g.

depending on load)

Check the speed and record.

Contact supplier of conveying

system.

Label with not suitable adhesive,

insufficient initial adhesion.

Change label quality.

Wrong parameterization.

Check time- and delay settings

of the responsible configuration

parameters (blow-, extension-

…)

The desired rate of

application can not be

reached with the labe-

ler.

The required rate of application

from the conveyor exceeds the

specifications.

Check conveyor speed and the

product gap. Reduce conveyor

speed if possible.

Incorrect configuration parameter

values of the labeler. Excessive

cycle processing time.

Check the delay times. Inquire

Service Technician at the Hot-

line (s. page 8).

Machine functions

occur at random with-

out being initiated.

Product detector loose or vibrating

or being affected of reflecting light

from product surface.

Check the adjustments of the

sensors and inquire if needed a

Service-Technician at the Ser-

vice-Hotline (s. page 8).

Loose wiring connections.

Check all connections at la-

beler.

Incomplete label feed.

Powered rewinder is not switched

off by rewinder dancer arm.

Control the function of the

dancer arm. If the liner tenses,

the Rewinder has to stop.

The unwinder brake is not ap-

proved by unwinder dancer arm.

Control the function of the

dancer arm. If the label web

becomes more tense, the label

roll has to be unwinded easily.

No label feed possible. Tamp home sensor is broken or out

of adjustment.

Replace or adjust sensors as

needed or inquire Service

Technician at the Service-

Hotline (s. page 8).

Содержание Geset 100

Страница 2: ...Blank page ...