Chapter 7

Adjustment and initial operation

32708885 Geset 100

Version: 16.07.13

Page 46 of 77

GB

Insert label roll in labeler

Further information on adjustment of the labelers is described separately in provided

manual.

Additionally there is a threading pattern sticked on each labeler that shows the guiding of

the label web. Thread the label web accordingly. Please observe that for each labeler and

to the product to be labeled, there will be inserted the correct label roll.

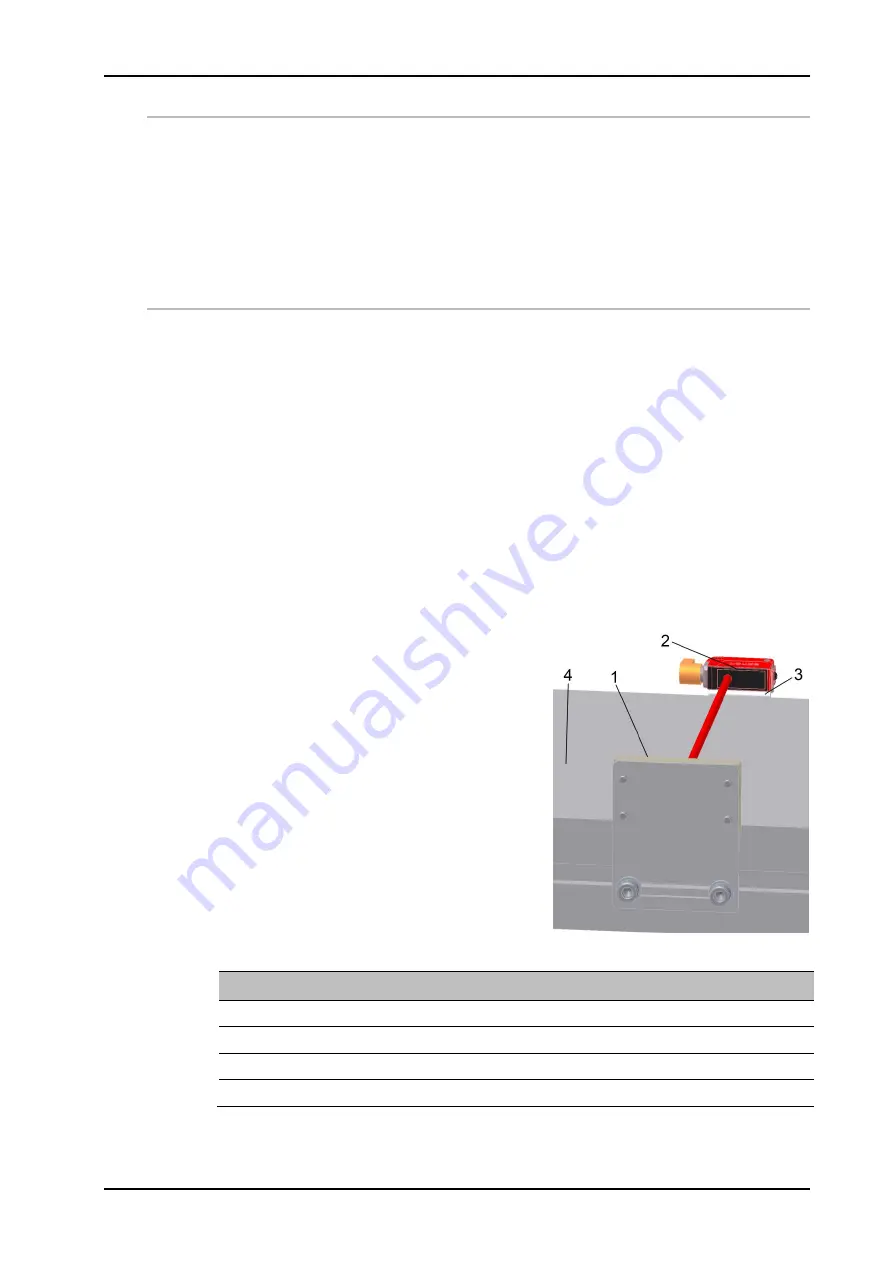

Adjust product light barrier

One light barrier is used for detection of the product at the labeling station. If a product is

detected, a signal is forwarded to the controller of the appropriate labeler to start the la-

beling process.

The point of time of the product detection is significant for the positioning of the label onto

the product. A delay value in the controller enables to change the label position exactly

per each millimeter (s. Alpha manual).

The light barriers are installed at a fix position ex-factory. A position change is not requi-

red. It is even undesired as it may impact the application rate of the labeling station unfa-

vorably.

Depending on product property a balancing of the sensor sensitivity may be necessary.

Particularly glossy and transparent products (e.g. foils) require a careful balancing of the

sensor. Further notes on balancing can be found in the manual of the sensor manufactu-

rer.

Fig. 7-8: Example of a product light barrier

No.

Description

1

REFLECTOR (EXAMPLE)

2

LIGHT BARRIER SENSOR (EXAMPLE)

3

SENSOR MOUNTING (EXAMPLE)

4

BASE CONVEYOR

Содержание Geset 100

Страница 2: ...Blank page ...