Chapter 7

Adjustment and initial operation

32708885 Geset 100

Version: 16.07.13

Page 41 of 77

GB

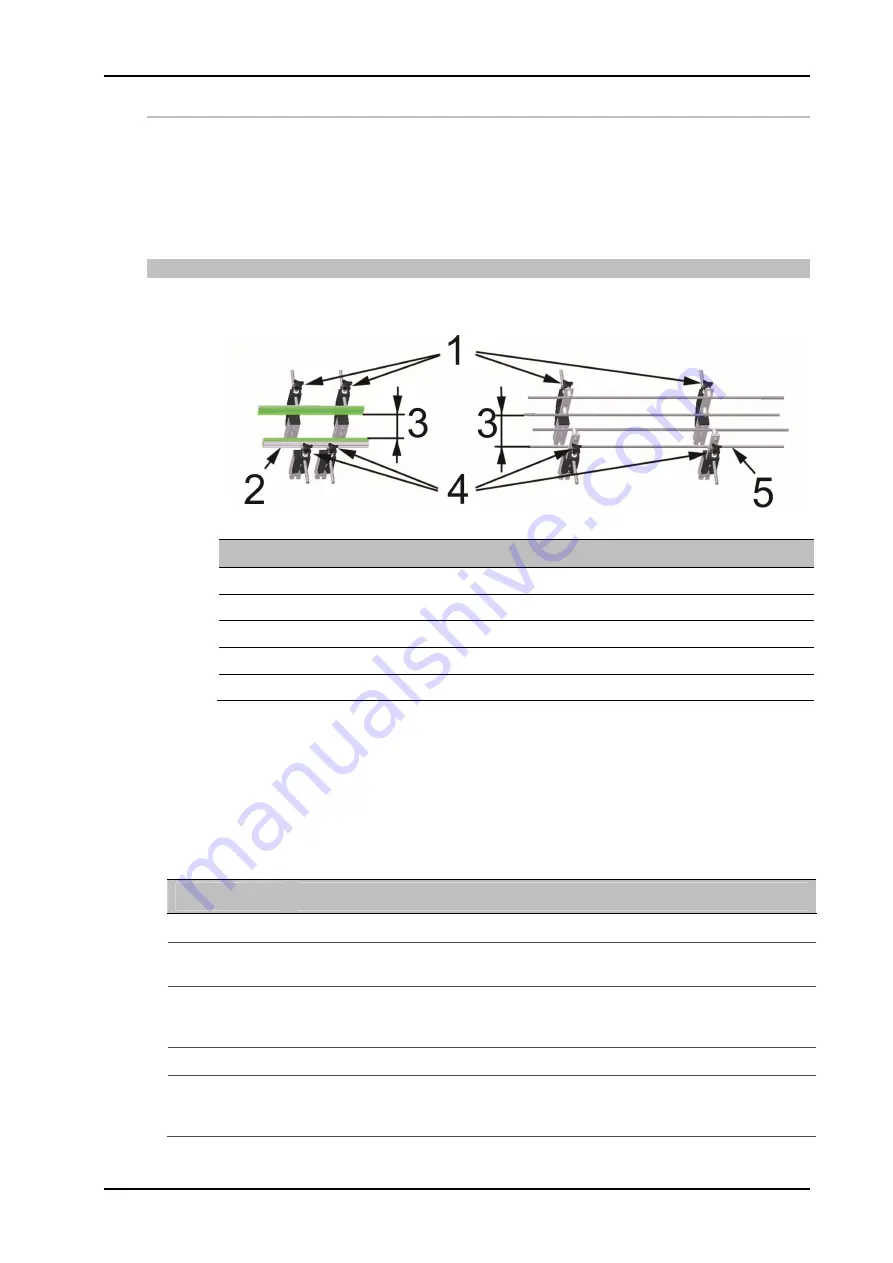

Adjust side guidance

The side guidances are used to determine the place at the conveyor where the product to

be labeled should be transported to. For side labeling, the adjustment is generally cen-

tered to the base conveyor.

At wrap-around labeling, products have to be transported laterally at the base conveyor’s

outside edge. I.e. at wrap-around labeling the products are positioned at base conveyor’s

outside edge at which also the fixed part of the wrapping unit is located

Information on adjustment of side guidance

The side guidances are adjusted by the star grips. The guidances have to be adjusted that

between product and side guiding is a crack of appr. 1-1,5 mm per side

Fig. 7-5:

Examples of side guidances

No.

Description

1

STAR GRIP SIDE GUIDANCE OPERATOR’S SIDE

2

SIDE GUIDANCE WITH WEAR STRIP

3

DISTANCE = P 2-3 mm

4

STAR GRIP SIDE GUIDANCE DRIVE SIDE

5

SIDE GUIDANCE WITH RODS

Requirements

¥

Labeling system is turned off.

¥

2 sample products.

¥

No transportation of products.

Please adjust the side guidances as follows.

Step

Procedure

1

Loosen the star grips.

2

Open the side guidances and place one sample product at beginning and

end.

3

Adjust the side guidance to the required criteria (s. section above). Observe

a distance of 1 - 1,5 mm to the product. (In infeed passage this distance can

be adjusted larger.)

4

Tighten the star grips.

5

Check the adjustment by moving a sample product through the side guid-

ances. The sample product has to slide easily through the guidance at each

passage.

Содержание Geset 100

Страница 2: ...Blank page ...