I N S T R U C T I O N S

598/669/1896/1994 Stand-Up Toggles

Fits Traveler Cars:

3163/3165/T3200 Series

N15W24983 Bluemound Rd • Pewaukee, WI 53072-4974 USA.

Tel: (262) 691-3320 • Fax: (262) 701-5780

Web: harken.com • Email: [email protected]

Parts List

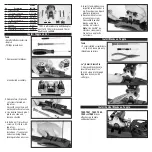

Replacing Polyurethane Stand-Up Device

1. Remove stainless toggle

from car.

Tip:

mark top of toggle

to make installation of new

stand-up device easier.

2. Use pliers to squeeze

circular base of stand-up

device; work device up

and out the side.

3. Install replacement piece

by squeezing circular base

of stand-up device and

inserting it from side of

toggle.

Note:

do not use pliers

to squeeze new stand

up device while installing.

This will damage part.

Tip:

use soap on circular

portion of stand-up device.

Printed in USA 4521 11/13

598, 1896 Big Boat Stand-Up Toggles Fit

Mainsheet Blocks

Swivel Ø (A)

Clevis Pin Ø (B)

Midrange

9

/

16

" (14.5 mm)

5

/

16

" (8 mm)

Cruising ESP 57 mm

9

/

16

" (14.5 mm)

5

/

16

" (8 mm)

Cruising ESP 75 mm

19

/

32

" (15 mm)

5

/

16

" (8 mm)

57 mm Big Boat Double

5

/

8

" (16 mm)

5

/

16

" (8 mm)

57 mm Big Boat Triple

5

/

8

" (16 mm)

5

/

16

" (8 mm)

75 mm Big Boat Single

5

/

8

" (16 mm)

5

/

16

" (8 mm)

75 mm Big Boat Spriddle

5

/

8

" (16 mm)

5

/

16

" (8 mm)

Control Blocks - 598/669

End Controls

Purchase

2650, 2600, 1950, 1951

3168, 3173, E3230, E3230.HL

2:1

2650, 2601, 1951, 1959

3169, 3170, E3240, E3240.HL, E3246

3:1

2638, 2602, 1952, 1960

3169, 3170, 3183, E3250, E3250.HL

4:1

2640, 2604, 1954

3186, 3193

6:1

These are a sample of combinations. Many more combinations are available.

Traveler Cars:

Clean by frequently flushing with fresh water. Periodically clean car by

squirting a detergent/water solution into center openings. Roll car back and forth to

distribute evenly then flush bearings with fresh water.

Do not use spray lubricants because ball bearings may skid not roll. Apply one to two

drops of McLube

®

OneDrop to ball contact surfaces of track. Roll car back and

forth through OneDrop several times to distribute onto bearings. Wipe remaining

OneDrop off track. OneDrop is preferred but you can also use one to two drops of a light

machine oil. Too much oil attracts dirt.

Track:

Clean with detergent and water.

Important! Exposure to some teak cleaners and other caustic solutions can result

in discoloration of part and is not covered under the Harken warranty.

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken

®

catalog.

Maintenance

Warranty

Inspect

Frequently inspect shackles and control block fittings for signs of fatigue and replace as

necessary. Make sure every installation includes Harken track end stops. Arrange control

tackle so cars do not hit end stops under load.

Strictly follow all instructions to avoid an accident, damage to

your vessel, personal injury or death. See www.harken.com/

manuals for additional safety information.

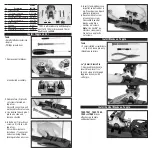

2600, 2601, 2602, 2604,

2638, 2640 and 2650

blocks

attach using shackle

and becket spacer.

Install Control Blocks on Toggle (Continued)

*

1994, 669 includes H-30392B adapter post to fit 100 mm blocks and 75 mm double and spriddle

.

Top

15

/

16

"

23 mm

1

1

/

8

"

25 mm

15

/

16

"

23 mm

1

1

/

8

"

25 mm

Top

1896

1994*

598

669*

No.

Description

Part No.

1896

1994*

1 Large cotter pin

HFS181

HFS181

2

5

/

16

" (8 mm) clevis pin

HCP208

H-21164A

3 BB stand-up toggle

H-17343C H25142C

4 Polyurethane stand-up device MP-1839

MP-1839

5 Blue Loctite

®

833

833

6 Replacement Set Screw (2)

HFS1050

HFS1050

Loctite

®

is a trademark of Henkel AG & Company KGaA.

McLube

®

is a registered trademark of McGee Industries, Inc.

1 2

3

4

5

6

6