IM_ONE_Safety-07

www.ueonline.com

6

The One Series

Field Safety System™

enclosure includes two conduit openings,

one intended for the high-power SAFETY RELAY OUTPUT (SRO) wiring and the

other intended for low-level signal and analog 4-20 mA wiring. 4-20 mA signals

shall be wired using a shielded/twisted pair to minimize the effects of electrical

interference. Please follow local electrical code requirements for explosion/flame

proof instrumentation.

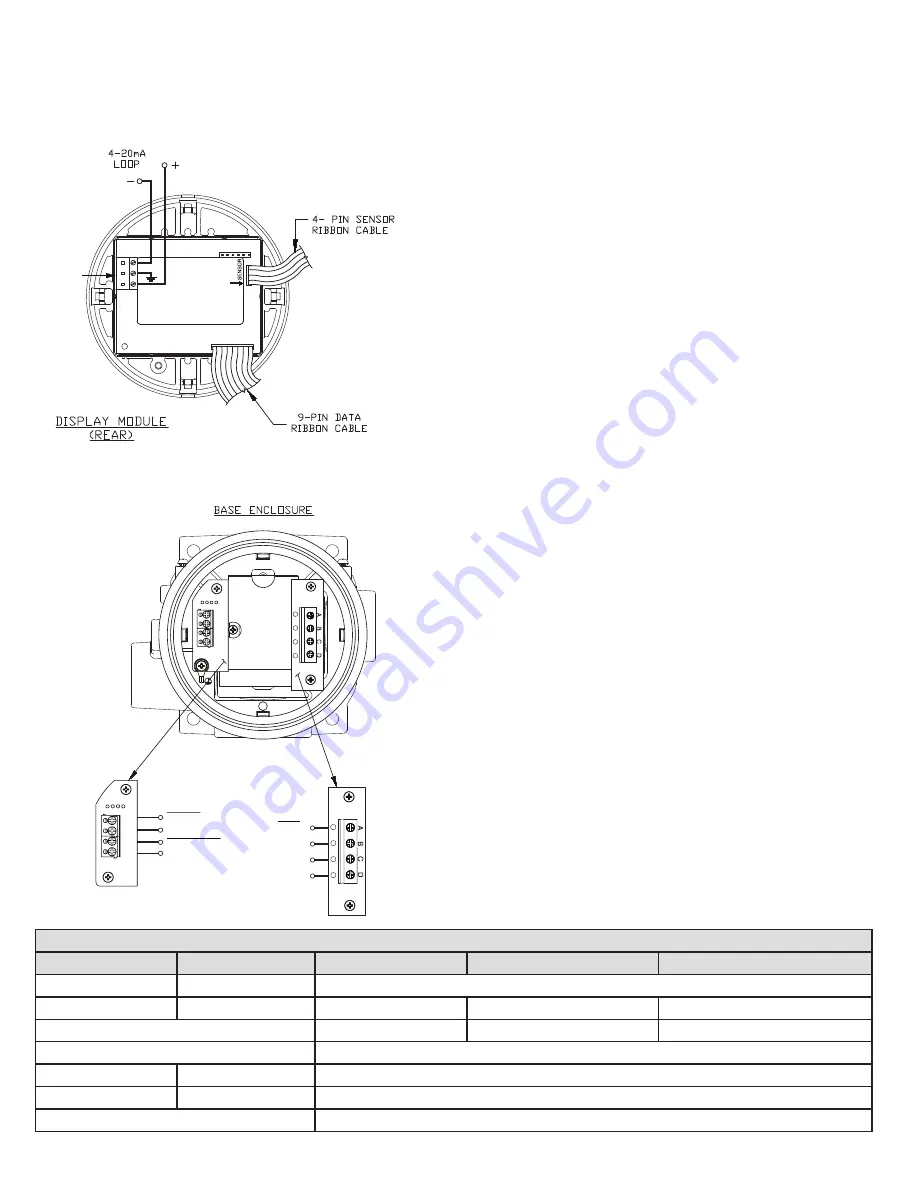

The diagrams in Figures 5 and 6 provide a rear view of the display module after

it has been removed from the base enclosure and an inside view of the base

enclosure circuit boards. Terminal Block 1 (TB1) is located on the display module.

All other terminal blocks (TB2 - TB4) are located inside the base enclosure.

Model 2SLP is loop-powered and is connected directly to an analog input of a PLC

or DCS via TB1 providing a 4-20 mA analog signal (see Table 3). (Polarity must

be observed). The loop connection powers the entire One Series

Field Safety

System™

, including the Safety Relay Output switch actuation. The auxiliary SAFETY

RELAY OUTPUT is connected via TB2 and is intended to switch an external load.

Refer to Table 3 for the SAFETY RELAY OUTPUT switch ratings.

Figure 6 shows the switch wiring connections located at TB2, TB3 and TB4 inside

the base enclosure. TB2 A and B terminals are provided for the external power

supply inputs to be switched by the Safety Relay Output. The SRO at TB2 C and D

terminals provide connections to the Safety Relay Output switch. Polarity must be

observed on all VDC switches. Please refer to the wiring diagrams shown on page

7.

The SRO Monitor function, if used, requires a connection to VDC (+) or VDC (-)

depending on whether the SRO circuit arrangement is sinking or sourcing (either

Neutral1 or Neutral2 for model 2SLP47). This connection allows the SRO current

to be measured that is sent out to an external load (final element), allowing the

IAW

TM

diagnostics to determine the integrity of the SRO wiring and if the SRO is

functioning properly.

NOTE:

As an alternative to loop power, model 2SLP may be wired directly to a

24 VDC power supply (+) and minus (-) terminals. In this wiring configuration,

power is provided for all switching and diagnostic functions but a 4-20 mA output

is not possible. This alternative method of powering the One Series

Field Safety

System™

may be used when loop power is not available and a 4-20 mA output is

not desired.

Two additional discrete outputs are available at TB3 and TB4 - SRO STATUS and

IAW OUTPUT. These are intended for use in Safety Instrumented Systems (SIS)

applications and for monitoring certain One Series Safety Transmitter functions.

These discrete signals are useful for voting logic schemes where the safety PLC can

decide to initiate an emergency shutdown (ESD) or an alarm depending on their

state. These outputs may also be used to distinguish between a process upset

(set point reached) or the IAW™

self-diagnostics detecting a fault with the One

Series

Field Safety System™

. Please refer to table 4 on page 15 for additional

information.

NOTE:

Do not exceed the maximum switch ratings of the SAFETY RELAY OUTPUT,

IAW™ OUTPUT and SRO STATUS signals or permanent damage to the One Series

Field Safety System™

may result. Please refer to Table 3.

WIRING DIAGRAMS - MODEL 2SLP

+

+

TB 2

+

-

RED

TB1

+

+

TB4

TB3

TB 2

TB2

TB 2

TB4

TB3

TB 2

SRO/SWITCH STATUS

TB2

IAW OUTPUT

SAFETY

RELAY

OUTPUT

+TB4-2

-TB4-1

+TB3-2

-TB3-1

NEUTRAL 1

NEUTRAL 2

LINE

SRO

Table 3 – Voltage and Current Maximum Ratings

Signal Name

Location

2SLP47

2SLP48

2SLP49

Power Supply

TB1: + & -

2-wire 20-40 VDC @ 4-20 mA (Loop or Fixed Current)

Safety Relay Output

TB2: C & D

12-250 VAC @ 5 mA-5 A

1

0-30 VDC @ 6 A

1

, 1.8 A

1

Pilot Duty 0-130 VDC @ 2.5 A

1

, Q150

1,2

Pilot Duty

With Relay Monitor Enabled

12-250 VAC @ 5 mA-5 A

1

10-30 VDC @ 5 mA-6 A

1

10-130 VDC @ 5 mA-2.5 A

1

Temperature Derating

1

1% per ˚C above 25˚C

SRO Status

TB3: 1 & 2

30 VDC @ 20 mA

IAW Output

TB4: 1 & 2

30 VDC @ 20 mA

2

Q150 Pilot Duty: 2.5 A (Continuous Current), 0.55 A (Make or Break), 69 VA

Figure 5 - Rear View Display Module

Figure 6 - Inside View Base Enclosure