6.

Use the front tractor wheel as a guide to maintain equal

lateral hole spacing with the previous pass.

7.

At the end of the aeration pass, raise the aerator and

disengage the PTO.

8.

If you back into a tight area (like a tee box), disengage

the PTO and raise the aerator to the highest position.

Use caution not to catch the turf guards on the turf.

9.

Always clear the area of all damaged machine parts,

such as broken tines, etc., to prevent anything from

being picked up and thrown by mowers or other turf

maintenance equipment.

10.

Replace broken tines, inspect and correct damage to

those still usable. Repair any other machine damage

before commencing operation.

Aerating Hard Ground

If the ground is too firm to obtain the desired coring depth,

the coring head can get into a “bouncing” rhythm. This is

due to the tines attempting to penetrate the hard pan. This

condition can be corrected by attempting one or more of

the following:

•

Best results are obtained after a rain or when turf has

been watered the previous day.

•

Reduce the number of tines per stomper arm. Attempt

to maintain a symmetrical tine configuration to evenly

load the stomper arms.

•

Reduce aerator penetration (depth setting) if the ground

is hard packed. Clean up the cores, water the turf, and

aerate again at a deeper penetration.

Aeration of soil types built on top of hard subsoils (i.e.

sand/soil cap placed over rocky ground) can cause undesired

hole quality. This is caused when the aeration depth is greater

than the soil cap and the subsoil is too hard to penetrate.

When the tines contact this subsoil the aerator may lift and

cause the top of the holes to become elongated. Reduce the

aeration depth sufficiently to avoid penetration into the hard

subsoil.

Using Needle Tines

Long slender tines used in either a needle tine head or mini

tine head can leave the front or rear of the hole tufted

or slightly deformed. Hole quality for this configuration

generally improves if the coring head speed is reduced 10 to

15% from full operating speed. For PTO powered aerators

reduced the engine speed until the PTO speed is around 460

to 490 rpm. The forward spacing is not effected by reducing

the engine speed. The pushed hole can also be affected by the

position of the rotalink damper assembly. Refer to

the Rotalink Assembly (page 21)

.

Avoiding Root Zone Lifting

Using the mini-tine heads in conjunction with larger coring

tines or large diameter solid tines can induce significant stress

on the root zone of the turf. This stress can fracture the root

zone and cause a lifting action to the turf. If this damage

occurs try one or more of the following:

•

Reduce the tine density (remove some of the tines).

•

Decrease the coring depth (suggested in 1/2 inch

increments).

•

Increase the forward hole spacing (change the tractor

transmission up one gear).

•

Decrease the tine diameter (solid or coring).

Adjusting the Rotalink

Assembly

The mounting height of the rotalink damper assembly affects

the reactive force applied to the stomper arm and ground

engagement during aeration. In the event of the front of the

hole being pushed (elongated or dimpled), a “stiffer” position

can help resist this push and improve hole quality. In the

event of the back of the hole being pushed (elongated or

dimpled) a “softer” position can improve the hole quality.

To adjust the rotalink assembly, proceed as follows:

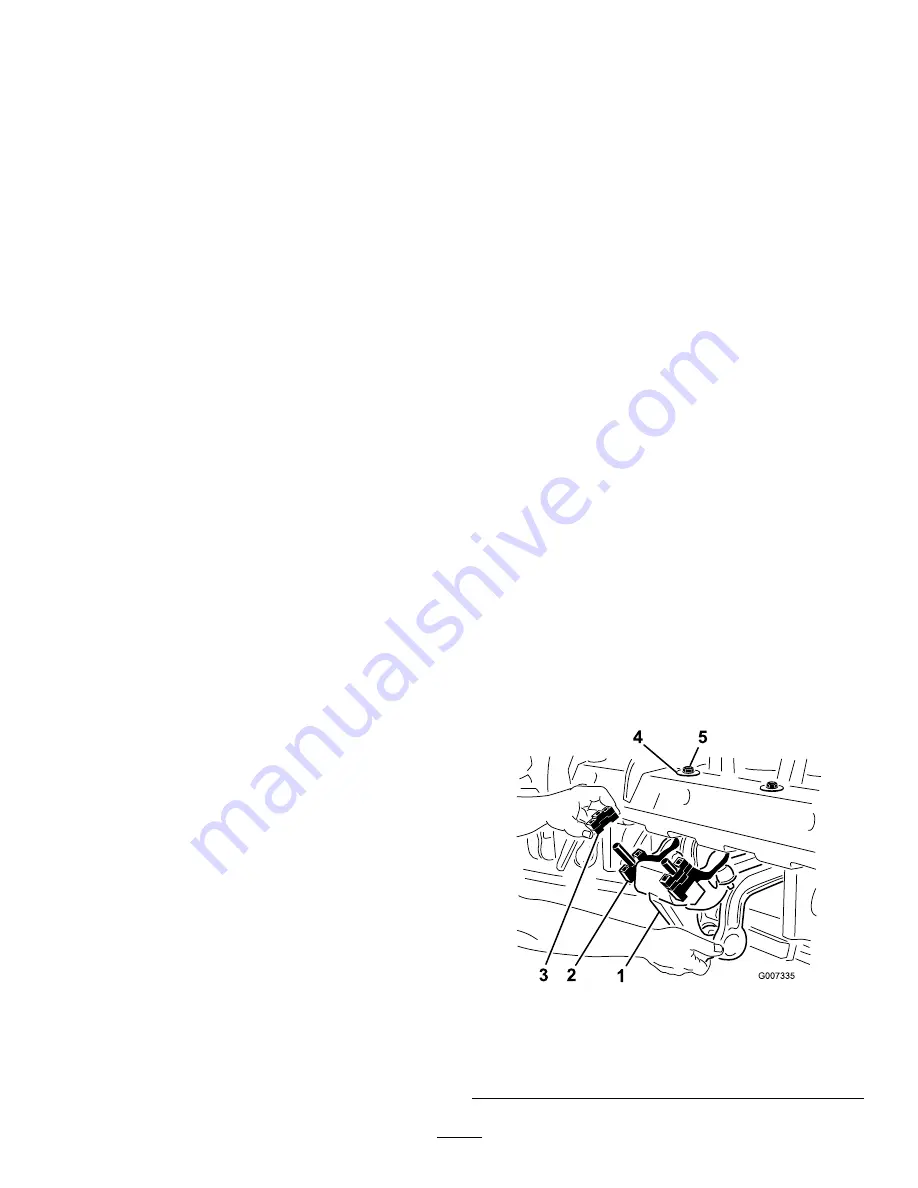

1.

Remove the 2 locknuts (1/2 inch) securing the rotalink

damper assembly to the underside of the coring head

frame (

2.

Lower the damper assembly to expose the spacers

(

).

3.

Move 1 or 2 spacers per side from the damper assembly

to the top of the coring head frame. Each spacer is

equivalent to 1/2 inch. The lower bumper spacer must

remain on the damper assembly.

g007335

Figure 26

1.

Rotalink damper assembly

4.

D washer

2.

Lower bumper spacer

5.

Locknut

3.

Spacer(s)

21

Содержание ProCore 1298

Страница 17: ...g028725 Figure 21 17...

Страница 18: ...g028724 Figure 22 18...