of the sprayer through the InfoCenter in the

Automatic mode.

Note:

An icon for the application rate will appear

in the display of the InfoCenter.

•

Press the

SPRAYER

-

MODE

switch to the right to

control the application rate of the sprayer by hand

in the Manual mode.

Note:

When switching from the Automatic mode

to the Manual mode, the icon for the application

rate will disappear in the display.

Switching between Sprayer Programming

Settings

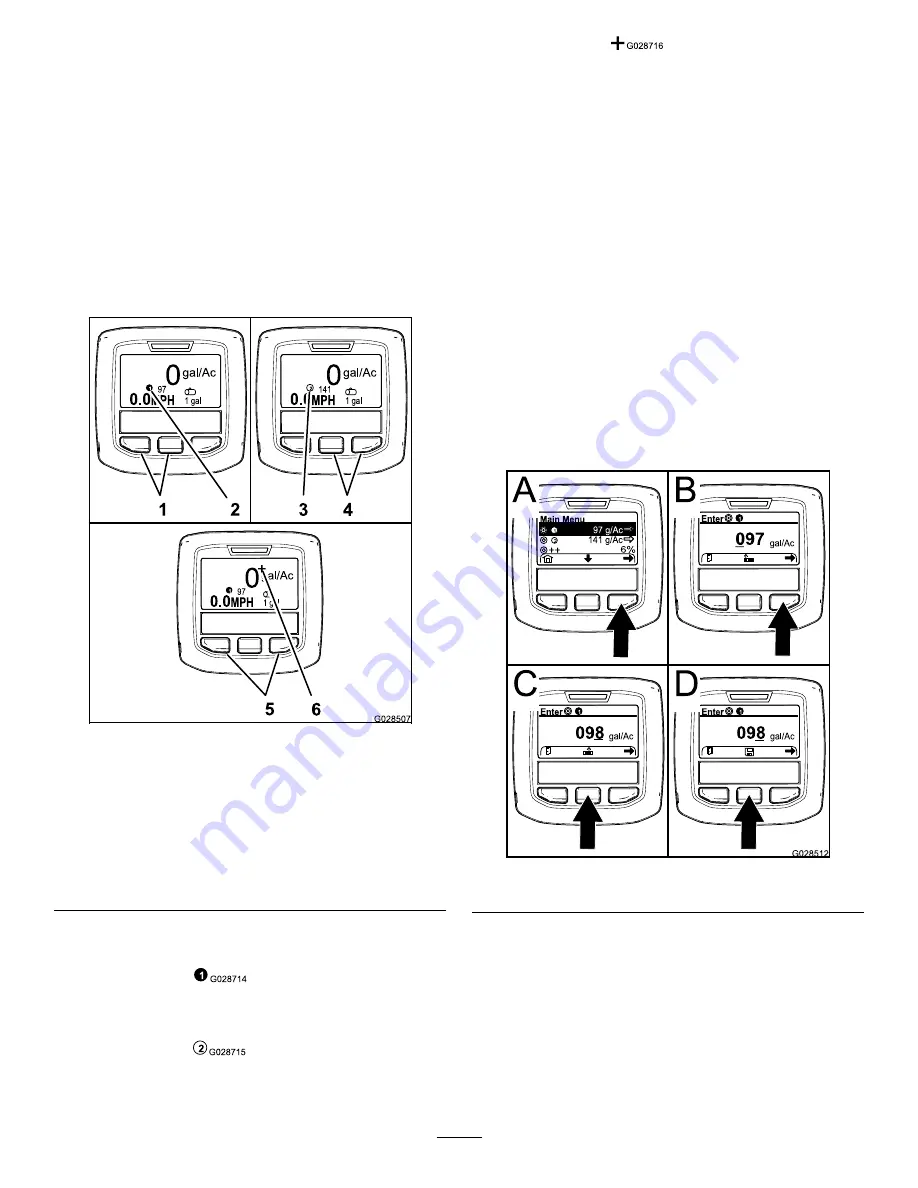

g028507

Figure 56

1.

Left and center

buttons—selecting

application rate 1

4.

Center and right

buttons—selecting

application rate 2

2.

Icon—application rate 1

5.

Left and right

buttons—selecting

application rate boost

3.

Icon —application rate 2

6.

Icon —application rate

boost

•

To select application rate 1, press the left 2 buttons

of the InfoCenter (

).

Note:

An icon

will appear.

•

To select application rate 2 (application rate),

press the right 2 buttons (

).

Note:

An icon

will appear.

•

To temporarily apply a boost application rate,

press and hold the 2 outer buttons (

).

Note:

An icon

will appear.

Note:

The application rate boost is an additional

percent above the active program (1 or 2)

application rate. Press and hold the buttons to

apply the boost application rate; release the

buttons to stop the boost rate.

Programming the Application Rate

and Application Rate Boost

HDX-Auto Model

Programming the Application Rate 1 and 2

1.

From the Home screen, press the center

selection button to navigate to the Main Menu.

2.

If needed, press the center selection button to

highlight the application rate for sprayer program

1 (

Note:

The icon for sprayer application rate 1

looks like the numeral 1 in a circle to the right of

a bull's-eye target.

g028512

Figure 57

3.

Press the right selection button to select sprayer

program 1 (A of

4.

Set the numerical value by pressing the following

selection buttons:

•

Press the right selection button (B of

) to move the cursor to the next numerical

position to the right.

•

Press the center selection button (C of

) to increase the numerical value (0 to 9)

44

Содержание Multi Pro WM 41240

Страница 79: ...Schematics g255886 Flow Diagram Sprayer System DWG 125 0699 Rev B 79...

Страница 80: ...Notes...

Страница 81: ...Notes...

Страница 82: ...Notes...