Troubleshooting

Problem

Possible Cause

Corrective Action

1. The power cord is disconnected at the

outlet or the machine.

1. Connect the power cord to the outlet

and/or the machine.

2. The power cord is worn, corroded, or

damaged.

2. Replace the power cord.

The electric starter does not turn

(electric-start models only).

3. The power outlet is not energized.

3. Have a qualified electrician energize

the outlet.

1. The key is not in the ignition.

1. Insert the key into the ignition.

2. The choke is in the O

FF

position and

the primer has not been pressed.

2. Move the choke to the O

N

position and

press the primer 3 times.

3. The fuel-shutoff valve is not open.

3. Open the fuel-shutoff valve.

4. The throttle is not in the F

AST

position.

4. Move the throttle to the F

AST

position.

5. The fuel tank is empty or the fuel

system contains stale fuel.

5. Drain and/or fill the fuel tank with

fresh fuel (not more than 30 days old).

If the problem persists, contact an

Authorized Service Dealer.

6. The spark-plug wire is loose or

disconnected.

6. Connect the wire to the spark plug.

7. The spark plug is pitted, fouled, or the

gap is incorrect.

7. Check the spark plug and adjust the

gap if necessary. Replace the spark

plug if it is pitted, fouled, or cracked.

8. The fuel-vent cap is restricted.

8. Remove the vent restriction or replace

the fuel cap.

The engine does not start or starts hard.

9. The engine-oil level in the engine

crankcase is too low or too high.

9. Add or drain oil to adjust the oil level in

the engine crankcase to the Full mark

on the dipstick.

1. The choke is in the O

N

position.

1. Move the choke to the O

FF

position.

2. The fuel-shutoff valve is not completely

open.

2. Open the fuel-shutoff valve.

3. The fuel tank is nearly empty or

contains stale fuel.

3. Drain and fill the fuel tank with fresh

fuel (not more than 30 days old).

If the problem persists, contact an

Authorized Service Dealer.

4. The spark-plug wire is loose.

4. Connect the wire to the spark plug.

5. The spark plug is pitted, fouled, or the

gap is incorrect.

5. Check the spark plug and adjust the

gap if necessary. Replace the spark

plug if it is pitted, fouled, or cracked.

The engine runs rough.

6. The engine-oil level in the engine

crankcase is too low or too high.

6. Add or drain oil to adjust the oil level in

the engine crankcase to the Full mark

on the dipstick.

26

Содержание 38812

Страница 2: ......

Страница 8: ...Setup 1 Installing the Chute No Parts Required Procedure g385316 6 ...

Страница 10: ...4 Installing the Chute Control Rod No Parts Required Procedure g257848 8 ...

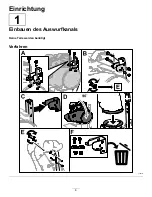

Страница 36: ...Einrichtung 1 Einbauen des Auswurfkanals Keine Teile werden benötigt Verfahren g385316 6 ...

Страница 38: ...4 Einbauen der Schaltstange für den Auswurfkanal Keine Teile werden benötigt Verfahren g257848 8 ...

Страница 62: ......

Страница 68: ...Mise en service 1 Montage de la goulotte Aucune pièce requise Procédure g385316 6 ...

Страница 70: ...4 Montage de la tige d orientation de la goulotte Aucune pièce requise Procédure g257848 8 ...

Страница 98: ...Montage 1 Monteren van het uitwerpkanaal Geen onderdelen vereist Procedure g385316 6 ...

Страница 100: ...4 De bedieningsstang van het uitwerpkanaal monteren Geen onderdelen vereist Procedure g257848 8 ...

Страница 124: ......