Maintenance

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the first 2 hours

• Inspect the traction cable and adjust it if necessary.

• Inspect the auger/impeller cable and adjust it if necessary.

After the first 5 hours

• Change the engine oil.

Before each use or daily

• Check the engine-oil level and add oil if necessary.

Every 100 hours

• Replace the spark plug.

Yearly

• Check the skids and the scraper and adjust them if necessary.

• Inspect the traction cable and adjust or replace it if necessary.

• Inspect the auger/impeller cable and adjust or replace it if necessary.

• Check the auger-gearbox oil and add oil if necessary.

• Change the engine oil.

• Lubricate the hex shaft.

Yearly or before storage

• Check the air pressure in the tires and inflate them to 116 to 137 kPa (17 to 20 psi).

• Drain the gasoline and run the engine to dry out the fuel tank and the carburetor at

the end of the season.

• Have an Authorized Service Dealer inspect and replace the traction-drive belt and/or

the auger/impeller drive belt, if necessary.

Maintenance Safety

Read the following safety precautions before

performing any maintenance on the machine:

•

Shut off the engine, remove the key, and wait

for all movement to stop before you leave the

operator’s position. Allow the machine to cool

before adjusting, servicing, cleaning, or storing it.

•

Always wear eye protection while performing an

adjustment or repair to protect your eyes from

foreign objects that the machine may throw.

•

Check all fasteners at frequent intervals for proper

tightness to ensure that the machine is in safe

working condition.

•

Do not change the governor settings on the engine.

Purchase only genuine Toro replacement parts

and accessories.

Preparing for Maintenance

1.

Move the machine to a level surface.

2.

Shut off the engine, remove the key, and wait for

all moving parts to stop.

3.

Disconnect the spark-plug wire. Refer to

Replacing the Spark Plug (page 24)

.

19

Содержание 38812

Страница 2: ......

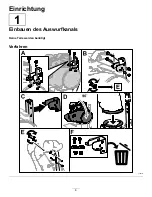

Страница 8: ...Setup 1 Installing the Chute No Parts Required Procedure g385316 6 ...

Страница 10: ...4 Installing the Chute Control Rod No Parts Required Procedure g257848 8 ...

Страница 36: ...Einrichtung 1 Einbauen des Auswurfkanals Keine Teile werden benötigt Verfahren g385316 6 ...

Страница 38: ...4 Einbauen der Schaltstange für den Auswurfkanal Keine Teile werden benötigt Verfahren g257848 8 ...

Страница 62: ......

Страница 68: ...Mise en service 1 Montage de la goulotte Aucune pièce requise Procédure g385316 6 ...

Страница 70: ...4 Montage de la tige d orientation de la goulotte Aucune pièce requise Procédure g257848 8 ...

Страница 98: ...Montage 1 Monteren van het uitwerpkanaal Geen onderdelen vereist Procedure g385316 6 ...

Страница 100: ...4 De bedieningsstang van het uitwerpkanaal monteren Geen onderdelen vereist Procedure g257848 8 ...

Страница 124: ......