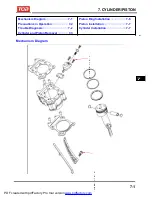

To this chapter contents

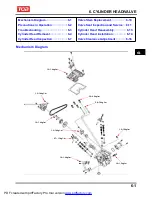

6. CYLINDER HEAD/VALVE

Valve Seat Inspection and Service

Clean up all carbon deposits onto intake and

exhaust valves.

Apply with emery slightly onto valve contact face.

Grind valve seat with a rubber hose or other

manual grinding tool.

Caution

●

Do not let emery enter into between valve stem

and valve guide.

●

Clean up the emery after corrected, and apply

with engine oil onto contact faces of valve and

valve seat.

Remove the valve and check its contact face.

Caution

Replace the valve with new one if valve seal is

roughness, wear out, or incomplete contacted

with valve seat.

Valve seat inspection

If the valve seat is too width, narrow or rough,

corrects it.

Valve seat width

Service limit: 1.6mm

Check the contact condition of valve seat.

Valve seat grinding

The worn valve seat has to be ground with valve

seat chamfer cutter.

Refer to operation manual of the valve seat

chamfer cutter.

Use 45

°

valve seat chamfer cutter to cut any rough

or uneven surface from valve seat.

Caution

After valve guide had been replaced, it has to be

ground with 45

°

valve seal chamfer cutter to

correct its seat face.

Valve seat width

Roughness

45

°

Use 32

°

cutter to cut a quarter upper parts out.

Old valve seat width

32

°

6-11

PDF created with pdfFactory Pro trial version

www.pdffactory.com

Содержание BLADE 250

Страница 1: ...BLADE 250 300 SERVICE MANUAL PDF created with pdfFactory Pro trial version www pdffactory com ...

Страница 145: ...13 BODY COVER Mechanism Diagram 13 1 13 PDF created with pdfFactory Pro trial version www pdffactory com ...

Страница 217: ...Home page Contents 18 ELECTRICAL DIAGRAM 18 18 1 PDF created with pdfFactory Pro trial version www pdffactory com ...

Страница 218: ...Home pae Contents 18 ELECTRICAL DIAGRAM Notes 18 2 PDF created with pdfFactory Pro trial version www pdffactory com ...