To this chapter contents

11. CRANKCASE / CRANK

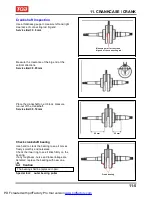

Crankshaft Inspection

Use a thickness gauge to measure left and right

clearance of connecting rod big end.

Service limit: 0.6 mm

Measure point for the crank

big end of the connecting rod.

Measure the clearance of the big end at the

vertical directions.

Service limit: 0.05 mm

Place the crankshaft on a V-block, measure

run-out of the crankshaft.

Service limit: 0.10 mm

90 mm

60 mm

Check crankshaft bearing

Use hand to crank the bearing to see it moves

freely, smoothly and noiseless.

Check the inner ring to see it links firmly on the

bearing.

If any roughness, noise and loose linkage are

detected, replace the bearing with new one.

Caution

The bearing shall be replaced in pair.

Special tool: outer bearing puller

Crank bearing

11-5

PDF created with pdfFactory Pro trial version

www.pdffactory.com

Содержание BLADE 250

Страница 1: ...BLADE 250 300 SERVICE MANUAL PDF created with pdfFactory Pro trial version www pdffactory com ...

Страница 145: ...13 BODY COVER Mechanism Diagram 13 1 13 PDF created with pdfFactory Pro trial version www pdffactory com ...

Страница 217: ...Home page Contents 18 ELECTRICAL DIAGRAM 18 18 1 PDF created with pdfFactory Pro trial version www pdffactory com ...

Страница 218: ...Home pae Contents 18 ELECTRICAL DIAGRAM Notes 18 2 PDF created with pdfFactory Pro trial version www pdffactory com ...