EN / 10-2015 / 1000683

© STULZ GmbH, Hamburg

-

60

-

Start-up

STULZUltraSonic-SystemforDirectRoomHumidificationBNB-

8.1.

Reports and checklists for STULZ UltraSonic humidifi ers

Wehaveprovidedyouwithachecklisttofacilitatestart-up.YoucanfindtheStart-upChecklist,TestRe-

portandMaintenanceChecklistonthefinalpagesofthismanualoravailabletodownloadonour

e-stulz

page at

www.stulz.de/en/e-stulz

.

TEST REPORT

STULZ GMBH

STULZ UltraSonic®

KLIMATECHNIK

Air Conditioning & Humidifying

Systems Division

Phone

+49 (0)40 55 85 252

Fax

+49 (0)40 55 01 315

KTR No.:

Testperformedby:

Date:

Customername:

Address,zipcode,city:

Order:

Contact:

Phone:

Unit type: Ultrasonic humidifier

BNB

ENS

SCA

FN

Unitname:

Serialno.:

Errormessage:

Electricalsupply:

230V/1Ph/50Hz

Comments:

Reason for test

Start-up

Service

Fault

General condition

(beforethetest)

Very good

Good

Adequate

Poor

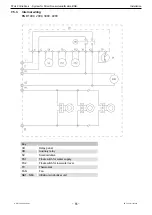

Electrical test of humidifier

Solenoid fill valve

OK

Damaged/tight

Comments:

Oscillators

Circuit 1

OK

Damaged

Comments:

Oscillators

Circuit 2

OK

Damaged

Comments:

Fan module

OK

Damaged

Comments:

Safety chain

Low level float switch

OK

Damaged

Comments:

Supply float switch

OK

Damaged/tight

Comments:

Auxiliary relay on PCB

OK

Damaged

Comments:

Thermostat

OK

Damaged

Comments:

Watercontactloop(ENS14+18)

OK

Damaged

Comments:

Ultrasonic Humidifier

STULZ GmbH Klimatechnik

Holsteiner Chaussee 283

22457 Hamburg, Germany

Company headquarters is Hamburg

Hamburg District Court HRB 16255

VAT ID No. DE 811 207 224

Directors:J.Stulz(Chairman),

Dr. U. Görge, M. Stulz,

M. Zimmermann

Start-up Checklist for STULZ UltraSonic® Humidifiers

The

technical documentation

of all units to be started up and their accessories is to hand

All humidifiers are precisely horizontal and securely mounted

Clearances and distances have been complied with

All units are accessible and operable

All humidifiers have an upstream actuation system

The oscillator PCBs are protected from voltage peaks by a TVS diode. This must be integrated

in the control system.

The electrical wiring is correct and complies with standards

Electrical power is available

Demineralized drinking water is connected to the supply pipe of all humidifiers

All water supply and drainage pipes and the overflow are correctly connected and secured

All accessories (e.g. water treatment system, sensors, fan, …) have been correctly fitted

All pipework channels and shut-off valves are known

Drinking water is available (if reverse osmosis or an ion exchanger is used, otherwise:

demineralized drinking water is available)

Duct units are locked with the airflow

The offtake capacity can be guaranteed by the upstream water softening equipment

The minimum pressure of 0.5 bar at the humidifiers is complied with

The maximum operating pressure of 6 bar at the humidifiers is not exceeded

The conductivity specified for the application is adhered to

Sensitive components are protected from or resistant to demineralized water

The humidifiers are protected from impurities that may arise (dust, pollen, etc.)

The flush valve is installed downstream from the humidifier in the drainage pipe, and is

below the humidifier

__________________________________

Date, signature

Job to be performed

Page Procedure and maintenance interval

Date

Signature

Date

Signature

Date

Signature

OK*

OK*

OK*

Visual inspection

48 -

Tightness of connections of water-bearing parts

-

Cleanness of filter

-

Outside of unit for impurities

-

Water tank for impurities, damage, microbial growth and

corrosion

-

Humidity sensor and ventilation slots for impurities

-

Solenoid valves for deposits

Every 3 months**

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

☐

51 -

Check oscillators for deposits

-

Check mist guide pipes for deposits

Every 6 months**

☐

☐

☐

☐

☐

☐

Leak test

48

Inspect all screw and push-in connections for leaks and a secure fit

Every 6 months**

☐

☐

☐

Clean the air filter

50

Open filter drawer, clean filter

Every 6 months**

☐

☐

☐

Clean the water tank

51

Remove housing cover and retaining plate together with mist

guide pipes (open water tank), clean and

disinfect with hydrogen peroxide solution

Every 6 months**

☐

☐

☐

☐

☐

☐

Inspect the electrical

system

52

Remove cover of control system and check electrics

Every 6 months**

☐

☐

☐

Replace float switches

55

Open water tank, remove float switch and fill valve unit

Approx. every 10,000 operating hours**

☐

☐

☐

Replace oscillators

58

Remove water tank, disconnect cables, detach oscillators

Approx. every 10,000 operating hours**

☐

☐

☐

*

Delete as applicable

**

Time intervals may be shorter in isolated cases, depending on local conditions