EN / 10-2015 / 1000683

© STULZ GmbH, Hamburg

-

16

-

Product description

STULZUltraSonic-SystemforDirectRoomHumidificationBNB-

4.3.

Description of unit

UnitsintheUltraSonicBNBmodelseries1000AtoBNB8000Aaredirectroomhumidifiersthatwork

on the principle of ultrasonic atomization of demineralized drinking water. The principal components of

this device are made from stainless steel or high-grade plastic. A fan integrated in the housing distributes

thecoldmist,whichisgeneratedinthewatertank,aroundtheroom.Thehumidifierisfullyassembled,

internally wired and leak tested at the factory, where it also undergoes testing under standard operating

conditions.

The polished stainless steel housing with removable stainless steel hood contains ultrasonic atomization

modules,asolenoidvalveandtwofloatswitches.Theairintakefeaturesamaintenance-friendlyinsert

withstainlesssteelguiderails,inwhichawashabledustfilterisinserted.

ThecompactUltraSonicatomizationmoduleismountedonthefloorofthewatertank.Toincreaseop-

erationalreliability,eachtransducerhasitsownelectronics,consistingofarectifier,vibrationcircuitand

transistoramplifier.Theultrasonicvibrationsproducedinthiswayareaimedatthesurfaceofthewater,

which is then atomized.

Thefandistributesthemistproducedinthewatertankaroundtheroom.Avariableairflowisgenerated,

to ensure that the aerosols dissipate rapidly.

Topreventlargerdropletsintheairflow,themistisblownoutbyspeciallyshapedmistguidetubes,con-

taining a droplet strainer and featuring a soft plastic wiper ring at the outlet. The unit has an air bypass as

standard, which allows mechanical calibration of the effective humidifying output.

Waterissuppliedbyaninletvalvewithanintegratedstainlesssteelfilterstrainer,whichisprotected

against overheating if it were to run dry. The water level is controlled by hermetically sealed, dust-insen-

sitivemagneticfloatswitches,whichadditionallymonitorunwanteddryrunning.

To achieve optimum atomization, the water level in the tank must be kept as constant as possible. In

additiontothefloatswitches,thesolenoidvalvealsoassistswithautomatedmonitoringofthewatersup-

ply.Ifthewaterinthetankfallsbelowthenormallevel,theupperfloatswitchswitchesandthesolenoid

valve opens the water supply to the tank. Once the normal water level is reached, the solenoid valve is

closed once more.

Operatingthehumidifierwithaninadequatewaterleveldamagesthetransducers.Topreventthis,the

lowerfloatswitchswitchesandoperatesarelayinthecontrolcabinet,whichturnsoffthepowersupply

totheunitifthewaterfallsbelowthesafetylevel:

Inaddition,athermostatswitchesthepoweroffifthetemperatureintheultrasonichumidifierrisesabove

a preset threshold. Varistors are installed to protect the electronics from voltage peaks.

EN / 06-2015 / 1000610

© STULZ GmbH, Hamburg

-

16

-

Product description

STULZUltraSonic-SystemforDirectRoomHumidificationBNB-

4.3.

Description of unit

UnitsintheUltraSonicBNBmodelseries1000AtoBNB8000Aaredirectroomhumidifiersthatwork

on the principle of ultrasonic atomization of demineralized drinking water. The principal components of

this device are made from stainless steel or high-grade plastic. A fan integrated in the housing distributes

thecoldmist,whichisgeneratedinthewatertank,aroundtheroom.Thehumidifierisfullyassembled,

internally wired and leak tested at the factory, where it also undergoes testing under standard operating

conditions.

The polished stainless steel housing with removable stainless steel hood contains ultrasonic atomization

modules,asolenoidvalveandtwofloatswitches.Theairintakefeaturesamaintenance-friendlyinsert

withstainlesssteelguiderails,inwhichawashabledustfilterisinserted.

ThecompactUltraSonicatomizationmoduleismountedonthefloorofthewatertank.Toincrease

operationalreliability,eachoscillatorhasitsownelectronics,consistingofarectifier,vibrationcircuitand

transistoramplifier.Theultrasonicvibrationsproducedinthiswayareaimedatthesurfaceofthewater,

which is then atomized.

Thefandistributesthemistproducedinthewatertankaroundtheroom.Avariableairflowisgenerated,

to ensure that the aerosols dissipate rapidly.

Topreventlargerdropletsintheairflow,themistisblownoutbyspeciallyshapedmistguidepipes,con

-

taining a droplet strainer and featuring a soft plastic wiper ring at the outlet. The unit has an air bypass as

standard, which allows mechanical calibration of the effective humidifying output.

Waterissuppliedbyaninletvalvewithanintegratedstainlesssteelfilterstrainer,whichisprotected

against overheating if it were to run dry. The water level is controlled by hermetically sealed, dust-insen-

sitivemagneticfloatswitches,whichadditionallymonitorunwanteddryrunning.

To achieve optimum atomization, the water level in the tank must be kept as constant as possible. In

additiontothefloatswitches,thesolenoidvalvealsoassistswithautomatedmonitoringofthewatersup

-

ply.Ifthewaterinthetankfallsbelowthenormallevel,theupperfloatswitchswitchesandthesolenoid

valve opens the water supply to the tank. Once the normal water level is reached, the solenoid valve is

closed once more.

Operatingthehumidifierwithaninadequatewaterleveldamagestheoscillators.Topreventthis,the

lowerfloatswitchswitchesandoperatesarelayinthecontrolcabinet,whichturnsoffthepowersupply

totheunitifthewaterfallsbelowthesafetylevel:

Inaddition,athermostatswitchesthepoweroffifthetemperatureintheultrasonichumidifierrisesabove

a preset threshold. Varistors are installed to protect the electronics from voltage peaks.

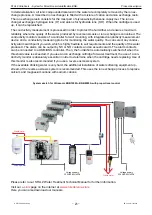

Schwimmerschalter Wasserversorgung, BNB

Befindet sich der Magnetring im Schwimmer in der unteren Position bleibt

der Schalter geöffnet.

Befindet sich der Magnetring im Schwimmer in der oberen Position wird der

Schalter geschlossen und somit die Stromversorgung des Magnetventils

und damit die Wasserversorgung hergestellt.

Normal operation for BNB

Water level

ON status

OFF status

Magnetic ring

Switch

The magnetic ring

opens the switch

to cut off the

power supply

OFF Status

Magnetring

Schalter

Der Magnetring hält den

Schalter in geöffneter

Position, so dass das

Magnetventil nicht

einschaltet und die

Wasserversorgung

unterbrochen bleibt.

Float

Fehlfunktion bei Vertauschen

Water supply

Keine Wasserversorgung